Non-noble metal doped molybdenum carbide hydrogen evolution electrode, preparation method thereof and application of electrode

A non-precious metal, hydrogen evolution electrode technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problem of low hydrogen evolution reaction rate, achieve the effect of improving hydrogen evolution performance, improving acetic acid production efficiency, and avoiding slow electron transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

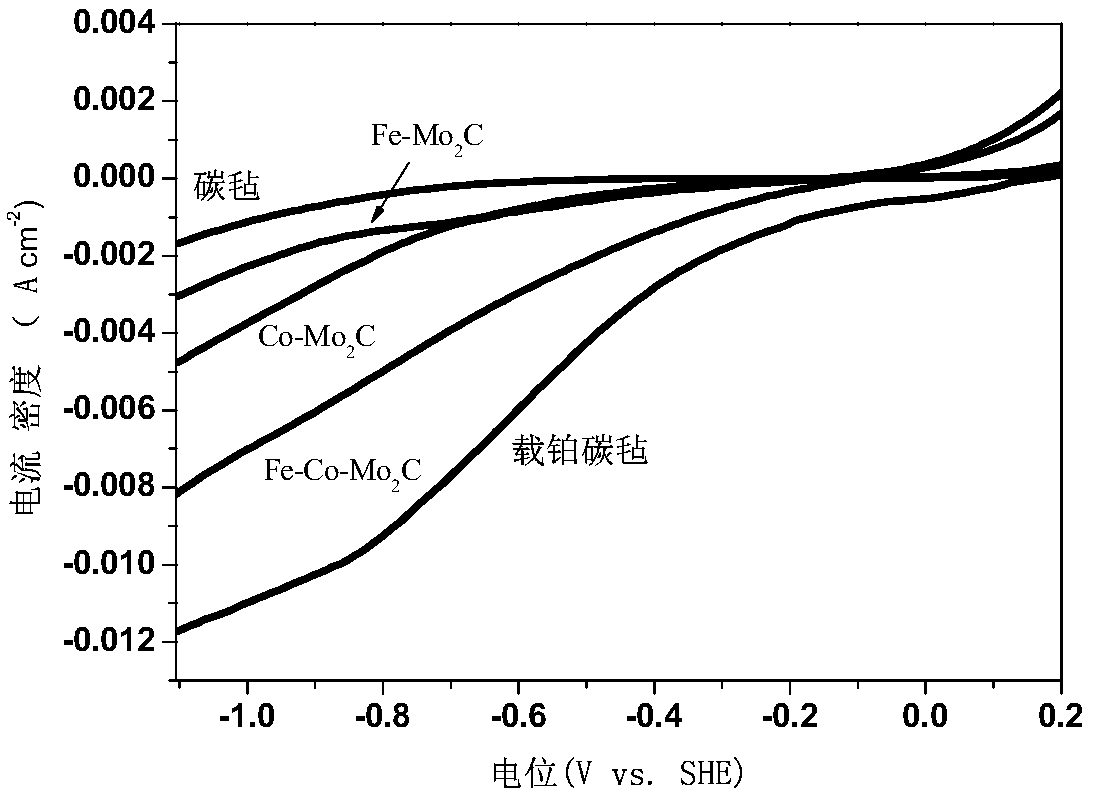

Embodiment 1

[0024] Dissolve 2 mol of ammonium molybdate, ferric chloride, and cobalt chloride in 250 mL of water at a molar ratio of 24:3:1, add 10 mL of benzylamine, and mix for 2 hours. Then the pH was adjusted to 5 with 1M HCl, stirred at 60° C. for 4 h to obtain a mixed solution. The solution was then filtered, washed with ethanol, and dried overnight at 60°C. The dried samples were placed in a tube furnace and reacted at 700 °C for 8 h under the protection of argon. The calcined sample was washed with 1M HCl, then deionized water, and dried to obtain a non-precious metal-doped molybdenum carbide catalyst. Then the catalyst was dissolved with a mixture of 3% Nafion solution with volume ratio of 3:10 and ethanol water solution with volume concentration of 95%. Carbon felt was pre-used with 1mol L -1 Soak in hydrochloric acid for 6 hours, wash to neutral drying, and then use 1mol L -1 Soak in sodium hydroxide aqueous solution for 6 hours, wash until neutral and dry, then add the pre...

Embodiment 2

[0029] Dissolve 1mol of ammonium molybdate, ferric chloride, and cobalt chloride in 250mL of water at a molar ratio of 10:1:1, add 10mL of benzylamine, and mix for 4h. Then the pH was adjusted to 5 with 1M HCl, stirred at 60° C. for 4 h to obtain a mixed solution. The solution was then filtered, washed with ethanol, and dried overnight at 60°C. The dried samples were placed in a tube furnace and reacted at 800°C for 10 h under the protection of argon. The calcined sample was washed with 1M HCl, then deionized water, and dried to obtain a non-precious metal-doped molybdenum carbide catalyst. The catalyst was then dissolved with a mixture of 5% Nafion solution and 95% ethanol aqueous solution with a volume ratio of 1:10. Carbon felt was pre-used with 1mol L -1 Soak in hydrochloric acid for 6 hours, wash to neutral drying, and then use 1mol L -1 soaked in sodium hydroxide for 6 hours, washed until neutral and dried, then added the pretreated carbon felt to the catalyst soluti...

Embodiment 3

[0032] Dissolve 5 mol of ammonium molybdate, ferric chloride, and cobalt chloride in 250 mL of water at a molar ratio of 30:2:1, add 10 mL of benzylamine, and mix for 3 hours. Then the pH was adjusted to 6 with 1M HCl, stirred at 80° C. for 3 h to obtain a mixed solution. The solution was then filtered, washed with ethanol, and dried overnight at 60°C. The dried samples were placed in a tube furnace and reacted at 900°C for 6 h under the protection of argon. The calcined sample was washed with 1M HCl, then deionized water, and dried to obtain a non-precious metal-doped molybdenum carbide catalyst. Then dissolve the catalyst with a mixture of 1% Nafion solution and 95% ethanol solution with a volume ratio of 3:10. Carbon felt was pre-used with 1mol L -1 Soak in hydrochloric acid for 6 hours, wash to neutral drying, and then use 1mol L -1 Soak in sodium hydroxide aqueous solution for 6 hours, wash until neutral and dry, then add the pretreated carbon felt to the catalyst sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com