Production method of astringency-removed persimmon wine

A persimmon wine and astringent removal technology, which is applied in the field of food processing, can solve the problems of insufficient profit, short production cycle, and waste of persimmon fruit resources, and achieve the effects of improving the astringent removal ability, short production cycle, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

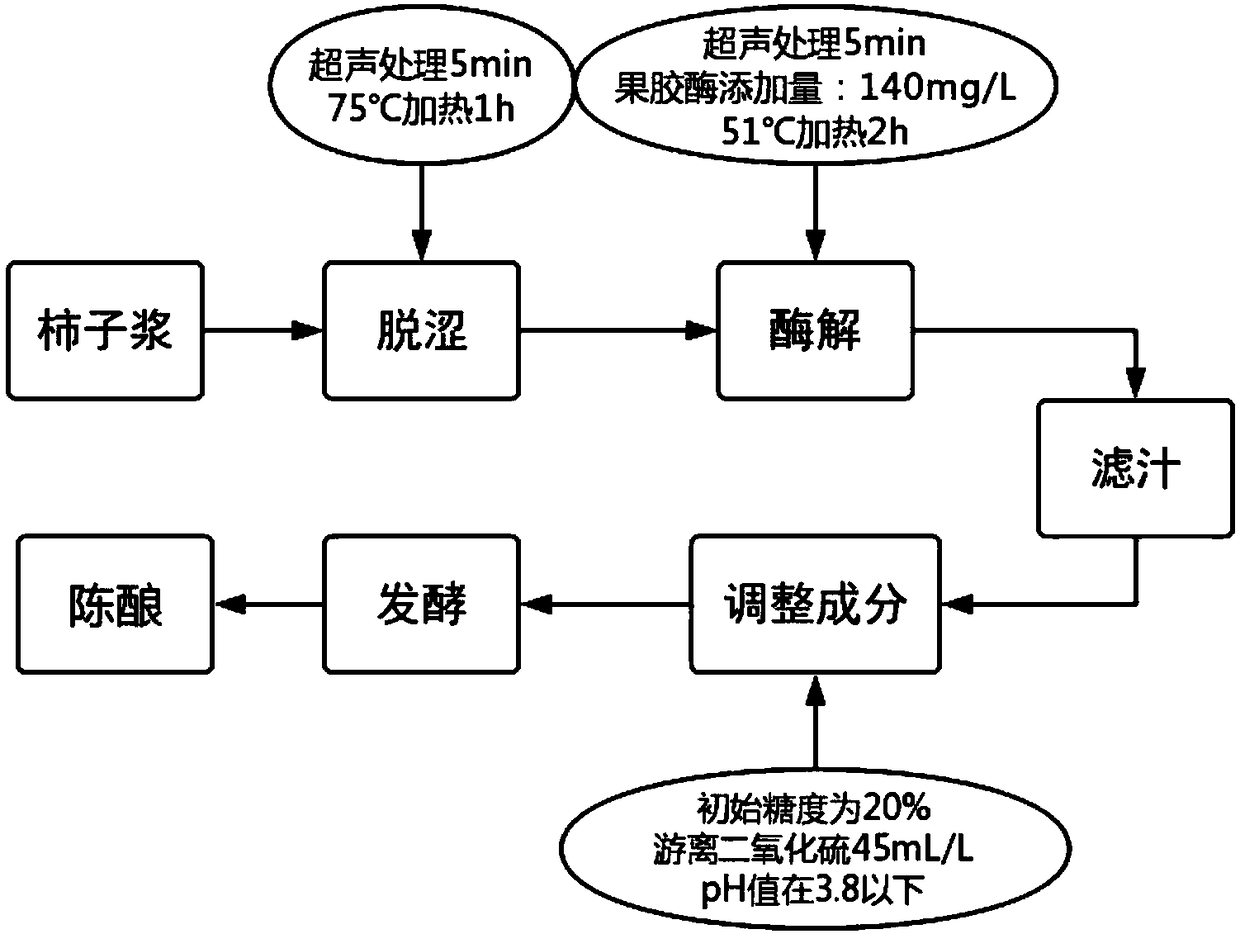

Image

Examples

Embodiment 1

[0050] A method for preparing deastringent persimmon wine. The method utilizes a combination of temperature adjustment and ultrasonic treatment to deastringent persimmons, adjusts the composition of clarified persimmon juice obtained by enzymatic hydrolysis and filtration, then adds Saccharomyces cerevisiae, and after 28 ℃ fermentation to prepare persimmon fermented wine.

[0051] Specifically, the steps are as follows:

[0052] (1) Raw materials: Take 4 persimmons frozen at -20℃, weighing about 1200g;

[0053] (2) Juicing: thaw the frozen persimmons at room temperature, separate the skin and flesh after cleaning, and squeeze the persimmon pulp;

[0054] (3) Deastringency treatment and preparation of clarified persimmon juice: Put the persimmon pulp into a container for ultrasonic treatment for 5 minutes, heat at 65°C for 40 minutes, and stir once every 10 minutes. After the heating is completed, when the temperature of the persimmon pulp drops to about 50°C, add pectinase in ...

Embodiment 2

[0059] A method for preparing deastringent persimmon wine. The method utilizes a combination of temperature adjustment and ultrasonic treatment to deastringent persimmons, adjusts the composition of clarified persimmon juice obtained by enzymatic hydrolysis and filtration, then adds Saccharomyces cerevisiae, and after 28 ℃ fermentation to prepare persimmon fermented wine.

[0060] Specifically, the steps are as follows:

[0061] (1) Raw materials: Take 10 persimmons frozen at -20℃, weighing about 3000g;

[0062] (2) Juicing: thaw the frozen persimmons at room temperature, separate the skin and flesh after cleaning, and squeeze the persimmon pulp;

[0063] (3) Deastringency treatment and preparation of clarified persimmon juice: put the persimmon pulp into a container for ultrasonic treatment for 5 minutes, heat at 75°C for 20 minutes, and stir once every 10 minutes. After heating, when the temperature of the persimmon pulp drops to about 50°C, add pectinase in an amount of 1...

Embodiment 3

[0068] A method for preparing deastringent persimmon wine. The method utilizes a combination of temperature adjustment and ultrasonic treatment to deastringent persimmons, adjusts the composition of clarified persimmon juice obtained by enzymatic hydrolysis and filtration, then adds Saccharomyces cerevisiae, and after 28 ℃ fermentation to prepare persimmon fermented wine.

[0069] Specifically, the steps are as follows:

[0070] (1) Raw materials: Take 20 persimmons frozen at -30℃, weighing about 6000g;

[0071] (2) Juicing: thaw the frozen persimmons at room temperature, separate the skin and flesh after cleaning, and squeeze the persimmon pulp;

[0072] (3) Deastringency treatment and preparation of clarified persimmon juice: Put the persimmon pulp into a container for ultrasonic treatment for 5 minutes, heat at 75°C for 40 minutes, and stir once every 10 minutes. After heating, when the temperature of the persimmon pulp drops to about 50°C, add pectinase in an amount of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com