A kind of synthetic water tolerance industrial gear oil and preparation method thereof

An industrial gear oil, water-based technology, applied in the petroleum industry, lubricating compositions, additives, etc., can solve the problems of shortened working life of oil products and equipment, decreased working performance, equipment corrosion, etc., and achieves significant energy saving effect and slow aging speed. , The effect of strong anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

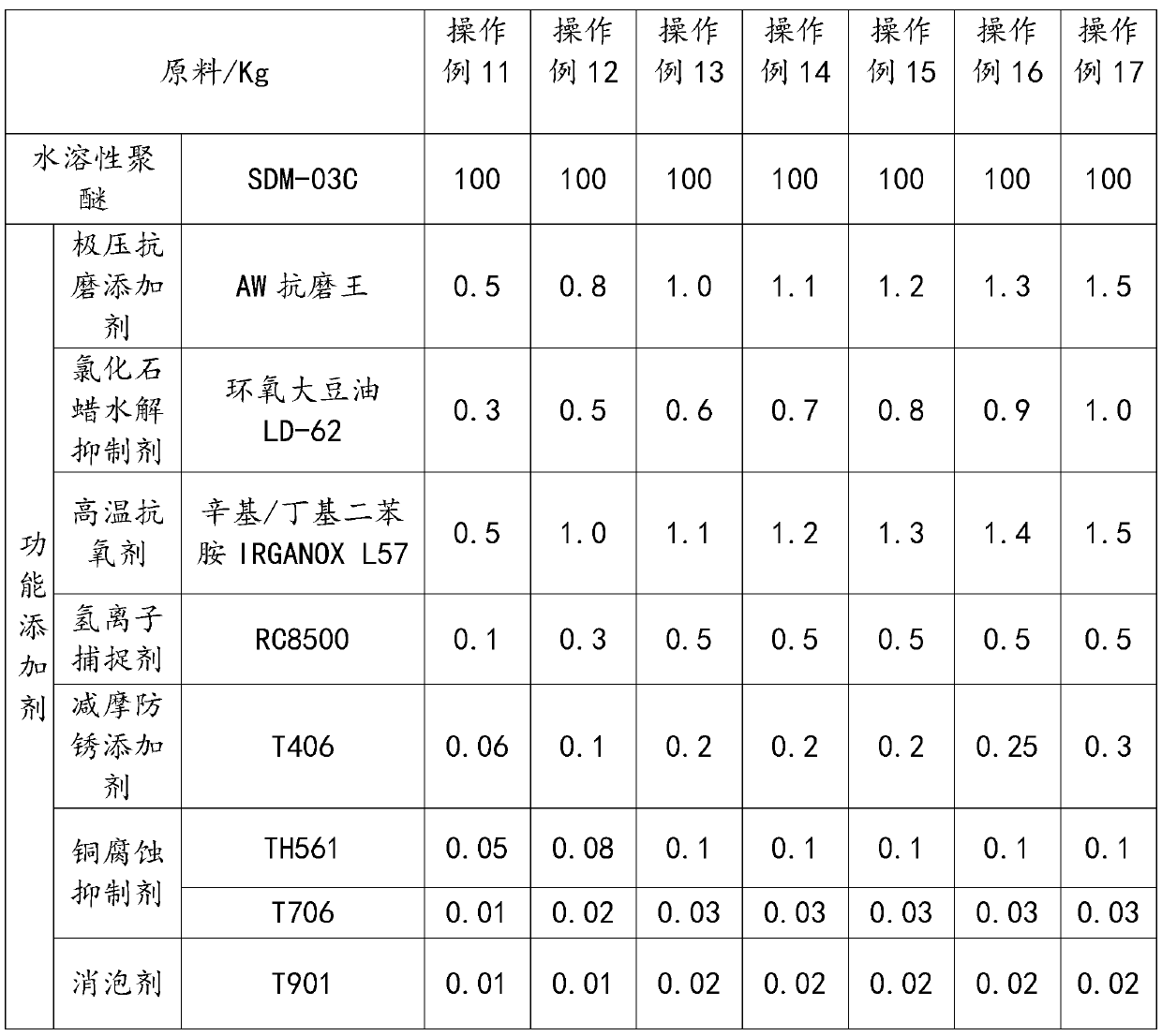

[0051] A gear oil of viscosity grade ISO VG100 is available, see Table 1.

[0052] The viscosity grade of table 1 is the raw material composition and the proportioning ratio of operation example 11-17 of 100#

[0053]

Embodiment 2

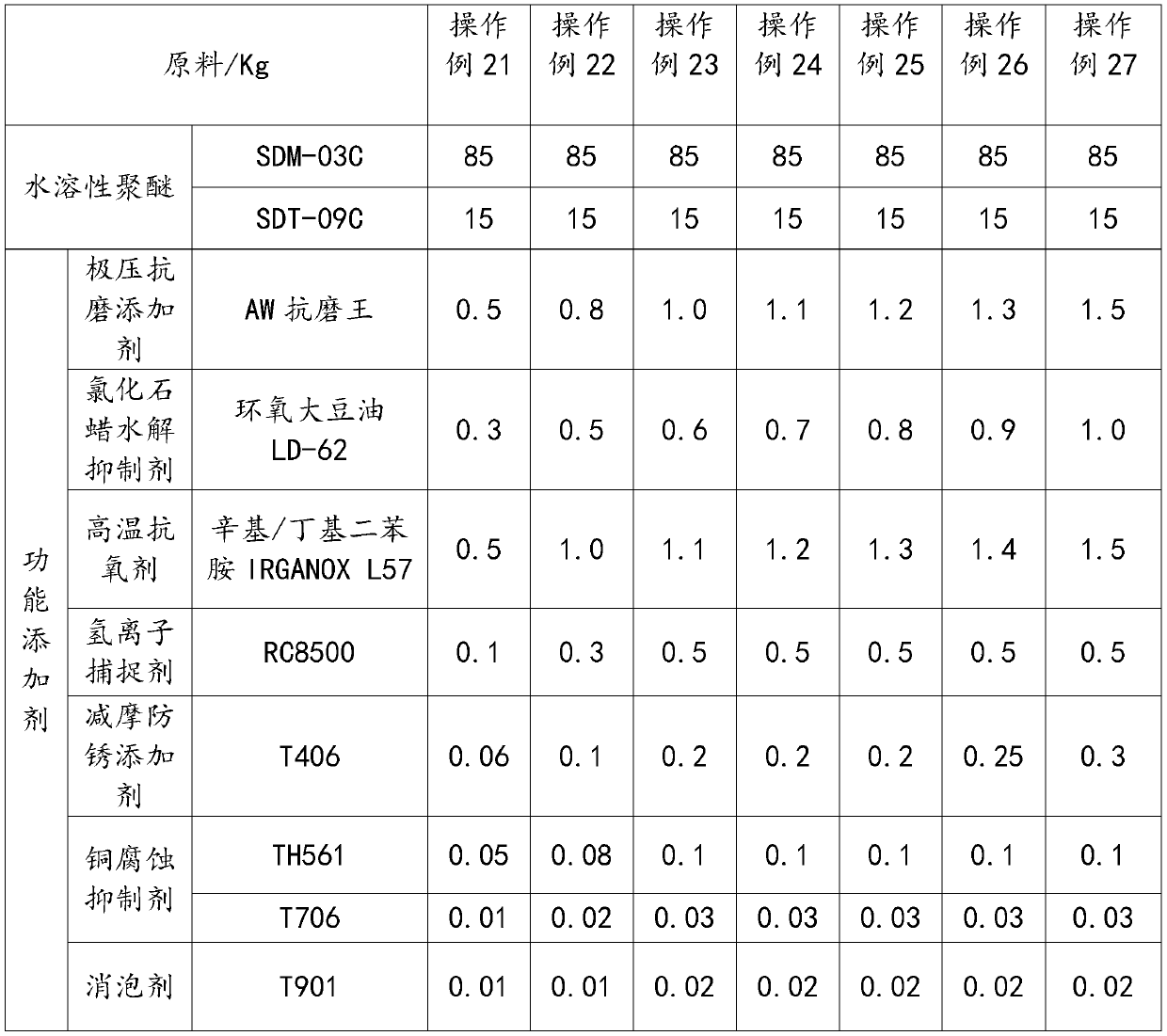

[0055] A gear oil of viscosity grade ISO VG150 is available, see Table 2.

[0056] The viscosity grade of table 2 is the raw material composition and the proportioning ratio of operation example 21-27 of 150#

[0057]

Embodiment 3

[0059] A gear oil of viscosity grade ISO VG220 is available, see Table 3.

[0060] Table 3 viscosity grade is the raw material composition and the proportioning ratio of operation example 31-37 of 220#

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com