High-filling surface finish carbon fiber master batches for plastic reinforcement and preparation method thereof

A technology for surface modification and carbon fiber, applied in the field of polymer plastic masterbatch and its preparation, can solve the problems of low surface energy of carbon fiber, and achieve the effect of simple preparation method and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

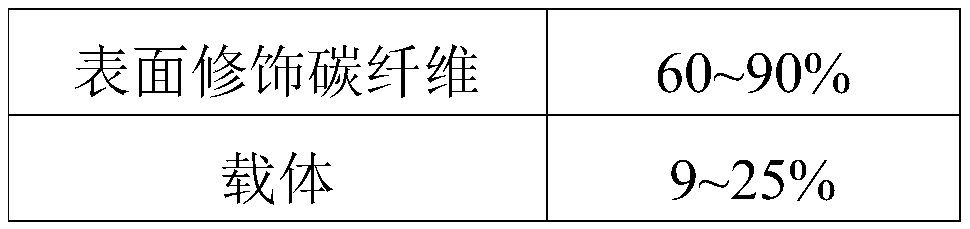

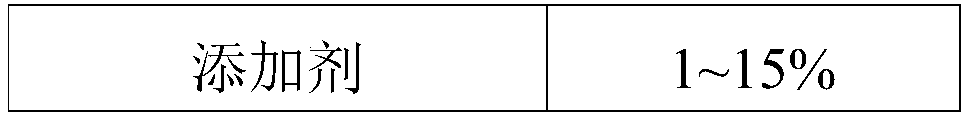

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing a highly filled surface-modified carbon fiber masterbatch for plastic reinforcement, comprising the following steps:

[0033] Preparation of surface-modified carbon fibers:

[0034] A. prepare the mixed solution of acetone and dehydrated alcohol, wherein, the content of described acetone is 50%;

[0035] B. Take polyacrylonitrile-based carbon fiber with high thermal conductivity, its diameter is 6-9μm, the heat-resistant temperature is 3000°C, and the density is 1.5-2.0g / cm 3 . The high thermal conductivity polyacrylonitrile-based carbon fiber is soaked in the mixed solution of acetone and absolute ethanol, and dried at 50° C. for 4 hours with ultrasonic to obtain the preliminary treated carbon fiber;

[0036] C. prepare the mixed acid solution of concentrated nitric acid and concentrated sulfuric acid, wherein, the content of described concentrated nitric acid is 20%;

[0037] D. Soak the preliminary treated carbon fib...

Embodiment 2

[0045] This embodiment provides a method for preparing a highly filled surface-modified carbon fiber masterbatch for plastic reinforcement, comprising the following steps:

[0046] Preparation of surface-modified carbon fibers:

[0047] A. prepare the mixed solution of acetone and dehydrated alcohol, wherein, the content of described acetone is 60%;

[0048] B. Take high thermal conductivity viscose-based carbon fiber with a diameter of 6-9μm, a heat-resistant temperature of 3000°C, and a density of 1.5-2.0g / cm 3 . Soak the high thermal conductivity viscose-based carbon fiber in the mixed solution of acetone and absolute ethanol, and dry it after ultrasonication at 60°C for 3 hours to obtain the initially treated carbon fiber;

[0049] C. prepare the mixed acid solution of concentrated nitric acid and concentrated sulfuric acid, wherein, the content of described concentrated nitric acid is 30%;

[0050] D. Soaking the preliminary treated carbon fibers prepared in step B in ...

Embodiment 3

[0058] This embodiment provides a method for preparing a highly filled surface-modified carbon fiber masterbatch for plastic reinforcement, comprising the following steps:

[0059]Preparation of surface-modified carbon fibers:

[0060] A. prepare the mixed solution of acetone and dehydrated alcohol, wherein, the content of described acetone is 80%;

[0061] B. Take high thermal conductivity viscose-based carbon fiber with a diameter of 6-9μm, a heat-resistant temperature of 3000°C, and a density of 1.5-2.0g / cm 3 . The high thermal conductivity viscose-based carbon fiber is soaked in the mixed solution of acetone and absolute ethanol, and dried at 70° C. for 3 hours with ultrasonic to obtain the initially treated carbon fiber;

[0062] C. prepare the mixed acid solution of concentrated nitric acid and concentrated sulfuric acid, wherein, the content of described concentrated nitric acid is 40%;

[0063] D. Soaking the preliminary treated carbon fibers prepared in step B in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com