Degradable plastic layer material of paper plastic bag

A technology for degrading plastic and layer materials, applied in the field of degradable plastic layers, can solve the problems of long degradation time, low cost of plastic bags, low mechanical strength, etc., and achieve the effects of avoiding environmental pollution, improving the burst resistance index, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

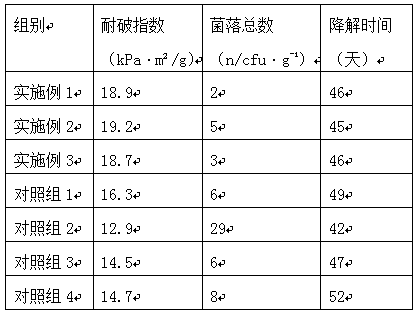

Examples

Embodiment 1

[0016] A degradable plastic layer material for a paper-plastic bag, comprising the following raw materials in parts by weight: 24 parts of polyvinyl alcohol, 6 parts of vinyl acetate, 1.5 parts of N-isopropylacrylamide, 38 parts of modified cornstarch, sodium base 4 parts of montmorillonite, 0.6 part of boric acid, 0.4 part of plasticizer;

[0017] The preparation method of described modified cornstarch is:

[0018] (1) Mix corn starch with copper chloride solution with a mass concentration of 7.5%, stir evenly, heat to 55°C, adjust the pH value to 5.5, and stir for 1.5 hours. After filtering, rinse the obtained filter residue with deionized water to medium properties, and then dried at a temperature of 52°C until the weight is constant to obtain an intermediate material;

[0019] (2) Add chlorosulfonic acid equivalent to 8% of its weight into N,N-dimethylformamide at a temperature of 4°C, and stir for 8 minutes to obtain a mixed solution;

[0020] (3) Mix the mixed solution...

Embodiment 2

[0024] A degradable plastic layer material for a paper-plastic bag, comprising the following raw materials in parts by weight: 22 parts of polyvinyl alcohol, 8 parts of vinyl acetate, 1 part of N-isopropylacrylamide, 40 parts of modified cornstarch, sodium base 5 parts of montmorillonite, 1.0 part of boric acid, 0.2 part of plasticizer;

[0025] The preparation method of described modified cornstarch is:

[0026] (1) Mix cornstarch with 6.5% copper chloride solution, stir evenly, heat to 60°C, adjust the pH value to 5.8, and stir for 1 hour. After filtering, rinse the obtained filter residue with deionized water to medium properties, and then dried at a temperature of 55°C until the weight is constant to obtain an intermediate material;

[0027] (2) Add chlorosulfonic acid equivalent to 6% of its weight into N,N-dimethylformamide at a temperature of 3°C, and stir for 10 minutes to obtain a mixed solution;

[0028] (3) Mix the mixed solution and the intermediate material at a...

Embodiment 3

[0032] A degradable plastic layer material for a paper-plastic bag, comprising the following raw materials in parts by weight: 26 parts of polyvinyl alcohol, 4 parts of vinyl acetate, 2 parts of N-isopropylacrylamide, 34 parts of modified cornstarch, sodium base 3 parts of montmorillonite, 0.2 part of boric acid, 0.6 part of plasticizer;

[0033] The preparation method of described modified cornstarch is:

[0034] (1) Mix corn starch with copper chloride solution with a mass concentration of 8.5%, stir evenly, heat to 50°C, adjust the pH value to 5.2, and stir for 2 hours. After filtering, rinse the resulting filter residue with deionized water to medium properties, and then dried at a temperature of 50°C until the weight is constant to obtain an intermediate material;

[0035] (2) Add chlorosulfonic acid equivalent to 10% of its weight into N,N-dimethylformamide at a temperature of 5°C, and stir for 5 minutes to obtain a mixed solution;

[0036] (3) Mix the mixed solution a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com