A kind of preparation method of cellulose acetate-based hybrid film

A technology of cellulose acetate and silver nitrate, applied in chemical instruments and methods, special treatment targets, coatings, etc., can solve the problems of poor mechanical properties, lack of practical value, and poor mechanical properties of pure silk fibroin solution, and achieve antibacterial Excellent effect, low equipment requirements, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

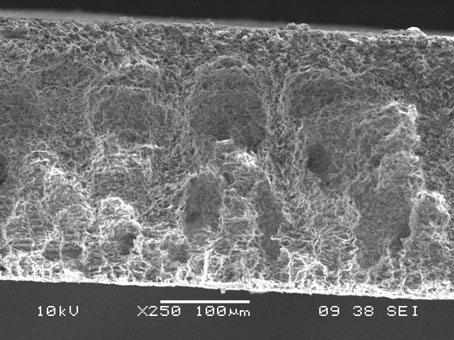

Image

Examples

Embodiment 1

[0044] One of the embodiments of the preparation method of a cellulose acetate-based hybrid membrane of the present invention comprises the following steps:

[0045] (1) Preparation of cellulose acetate solution: Weigh 9g of cellulose acetate particles and 90g of N,N-dimethylformamide in the ratio of 1:10 to add cellulose acetate and N,N-dimethylformamide to the reaction In the container, stir at a constant temperature at 25°C for 8 hours, and after the cellulose acetate particles are completely dissolved, a cellulose acetate solution with a mass fraction of 9.1% is obtained;

[0046] (2) Prepare the mixed solution: add silk fibroin powder with a particle size of 5 μm and a solid content of 62% to the above cellulose acetate solution, stir with a high-speed stirrer for 30 minutes, and then let it stand for 30 minutes to defoam, to obtain mixed solution;

[0047] (3) Preparation of cellulose acetate / silk fibroin hybrid film: Coat the mixed solution on a release paper with a th...

Embodiment 2

[0052] One of the embodiments of the preparation method of a cellulose acetate-based hybrid membrane of the present invention comprises the following steps:

[0053] (1) Preparation of cellulose acetate solution: Weigh 8g of cellulose acetate particles and 80g of N,N-dimethylacetamide into the reaction according to the ratio of 1:8 of cellulose acetate and N,N-dimethylacetamide In the container, heat and stir at 40°C for 8 hours. After the cellulose acetate particles are completely dissolved, a cellulose acetate solution with a mass fraction of 11.1% is obtained;

[0054] (2) Prepare the mixed solution: add silk fibroin powder with a particle size of 5 μm and a solid content of 65% to the above cellulose acetate solution, and then use a high-speed stirrer to stir for 30 minutes to obtain a well-mixed organic-inorganic mixture solution, left to defoam for 30 minutes to obtain a mixed solution;

[0055] (3) Preparation of cellulose acetate / silk fibroin hybrid film: Coat the mix...

Embodiment 3

[0060] One of the embodiments of the preparation method of a cellulose acetate-based hybrid membrane of the present invention comprises the following steps:

[0061] (1) Preparation of cellulose acetate solution: Weigh 10g of cellulose acetate particles and 65g of N,N-dimethylformamide into the reaction In the container, heat and stir at 45°C for 8 hours. After the cellulose acetate particles are completely dissolved, a cellulose acetate solution with a mass fraction of 13.3% is obtained;

[0062] (2) Prepare the mixed solution: add silk fibroin powder with a particle size of 5 μm and a solid content of 70% to the above cellulose acetate solution, and then use a high-speed stirrer to stir for 30 minutes to obtain a well-mixed organic-inorganic mixture solution, left to defoam for 30 minutes to obtain a mixed solution;

[0063] (3) Preparation of cellulose acetate / silk fibroin hybrid film: Coat the mixed solution on a release paper with a thickness of 0.05 mm, and quickly imme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com