Instant polyacrylamide for offshore oil displacing and synthesis method thereof

A technology of polyacrylamide and synthesis method, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor solubility, failure to meet the use requirements, slow dissolution speed, etc., to ensure shear Degradation and temperature resistance, improve salt resistance, increase the effect of molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

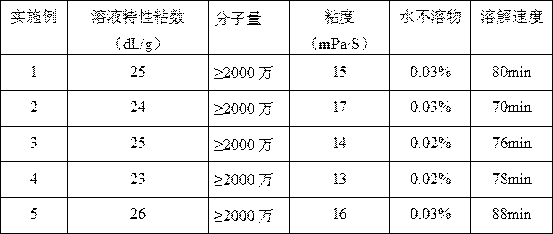

Examples

Embodiment 1

[0015] Add 724.6g of distilled water to a 1L jar, then add 11.5g of sodium hydroxide, dissolve evenly, slowly add 60g of functional monomer AMPS, dissolve evenly in a constant temperature water bath below 12°C, adjust the pH value to 12, and let it stand for 10 minutes Add 200g of refined AM monomer, 2g of sodium chloride, and 1.5g of urea, cool down to -2°C and transfer to a Dewar flask, pass through 99.999% high-purity nitrogen to remove oxygen, add 0.32g of EDTA after 10 minutes, and continue to pass through Add 0.1 g of azobisisoheptanonitrile after 20 minutes of deoxygenation with nitrogen, and then add 0.002 g of tert-butyl hydroperoxide after 20 minutes of deoxygenation with nitrogen, then add 0.01 g of ferrous ammonium sulfate after 2 minutes, and then continue to pass nitrogen to the solution Seal when it becomes sticky.

[0016] After the temperature of the solution rises to the highest value and cools down naturally for 2 hours, take out the colloid from the Dewar b...

Embodiment 2

[0018] Add 720.9g of distilled water to a 1L jar, then add 15.2g of sodium hydroxide, dissolve evenly, slowly add 80g of functional monomer AMPS, dissolve evenly in a constant temperature water bath below 12°C, adjust the pH value to 12, and let it stand for 10 minutes Add 180g of refined AM monomer, 1.5g of sodium chloride, and 2g of urea, cool down to -2°C and transfer to a Dewar flask, pass through 99.999% high-purity nitrogen to remove oxygen, add 0.16g of EDTA after 10 minutes, and continue to pass through Add 0.2 g of azobisisoheptanonitrile after deoxygenation with nitrogen for 20 minutes, then add 0.005 g of tert-butyl hydroperoxide after 20 minutes of deoxygenation with nitrogen, then add 0.006 g of ferrous ammonium sulfate after 2 minutes, and then continue to pass nitrogen to the solution Seal when it becomes sticky.

[0019] After the temperature of the solution rises to the highest value and cools down naturally for 2 hours, take out the colloid from the Dewar bot...

Embodiment 3

[0021] Add 723g of distilled water to a 1L jar, then add 13g of sodium hydroxide, dissolve evenly, slowly add 70g of functional monomer AMPS, dissolve evenly in a constant temperature water bath below 12°C, adjust the pH value to 12, and then add refined AM monomer 190g, sodium chloride 1.8g, urea 1.8g, cool down to -2°C and transfer to a Dewar flask, pass through 99.999% high-purity nitrogen to remove oxygen, add EDTA 0.2g after 10 minutes, continue to pass nitrogen Add 0.15 g of azobisisoheptanonitrile after deoxygenation for 20 minutes, then add 0.004 g of tert-butyl hydroperoxide after 20 minutes of deoxygenation with nitrogen, then add 0.008 g of ferrous ammonium sulfate after 2 minutes, and then continue to pass nitrogen until the solution becomes Seal when sticky.

[0022] After the temperature of the solution rises to the highest value and cools down naturally for 2 hours, take out the colloid from the Dewar bottle, granulate it into particles with a diameter of 3-5mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com