A kind of preparation method of macroporous strongly acidic styrene ion exchange resin

A technology of strong acid styrene and ion exchange resin, applied in the direction of ion exchange, cation exchange, organic cation exchanger, etc., can solve the problems of environmental protection, poor resin quality, cumbersome resin production process, etc., and achieve strong anti-pollution performance, Reduce production cost, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

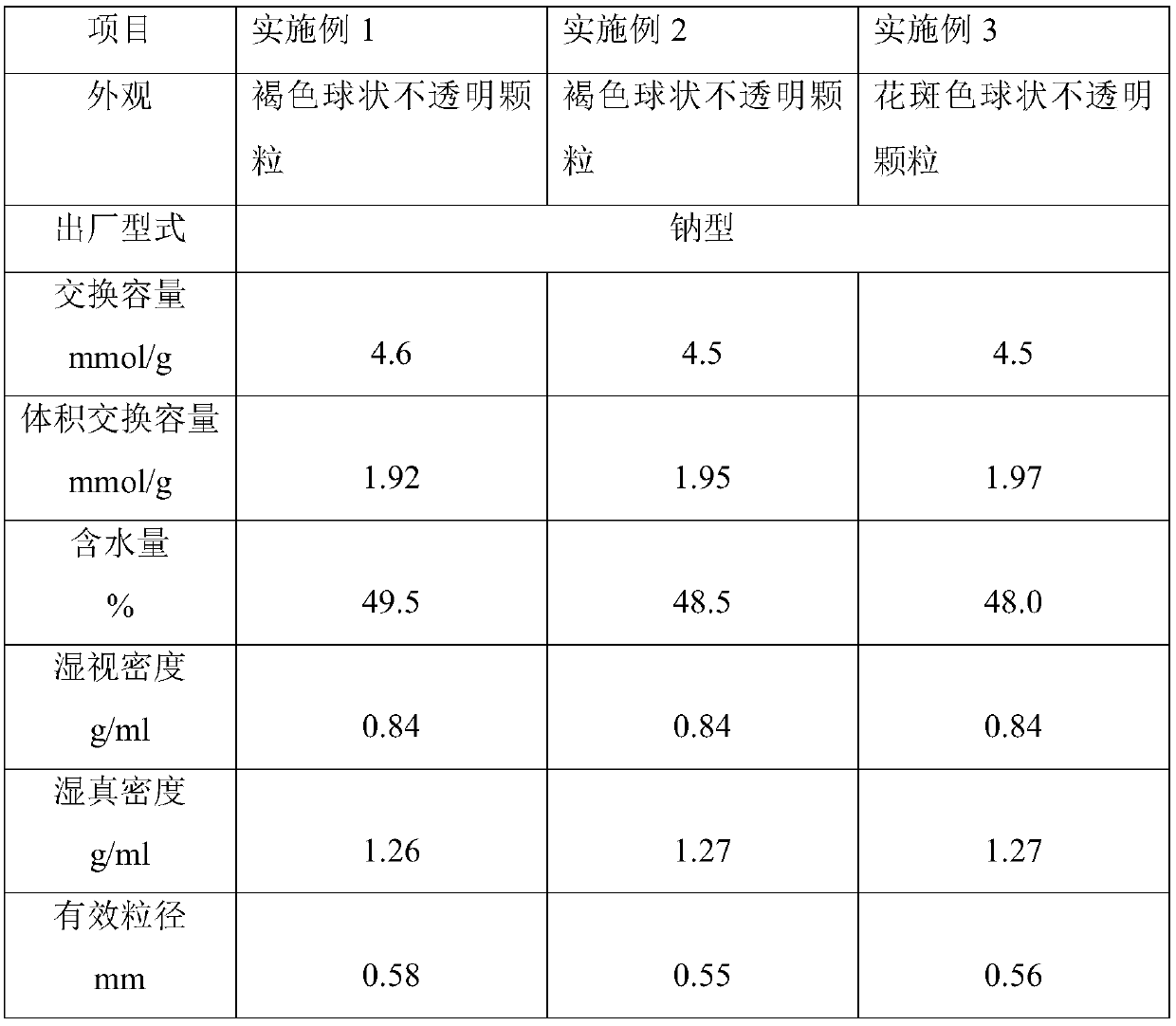

Embodiment 1

[0029] Macroporous strongly acidic styrene-based cation exchange resin, the synthesis steps are as follows (the following proportions are calculated based on 1 ton of finished resin):

[0030] (1) Preparation of water phase material: 550Kg of demineralized water is added to the reactor, then 25Kg of industrial salt is added, until it is completely dissolved, 15Kg of polyvinyl alcohol aqueous solution of methylene blue 1g and 1788 (4%) aqueous solution is added, fully stirred Mix and heat up to 58°C for later use;

[0031] (2) Prepare the organic phase: take 200Kg of styrene and add it to the batching kettle, add 10Kg of polystyrene resin, stir for 3 hours, wait for it to fully dissolve, then add 20Kg of solid paraffin, heat up to 60°C and stir for 20min, after it is fully dissolved, pump Add divinylbenzene 30Kg, and add initiator benzoyl peroxide 2.5Kg, stir 5min, obtain organic phase, standby;

[0032] (3) Polymerization operation: Put the prepared organic phase into the wat...

Embodiment 2

[0036] Macroporous strongly acidic styrene-based cation exchange resin, the synthesis steps are as follows (the following proportions are calculated based on 1 ton of finished resin):

[0037] (1) Preparation of water phase material: 580Kg of demineralized water is added to the reactor, then 28Kg of industrial salt is added, and it is completely dissolved, then 16Kg of polyvinyl alcohol aqueous solution of methylene blue 1g and 1788 (4%) aqueous solution is added, fully stirred Mix and heat up to 58°C for later use;

[0038] (2) Prepare the organic phase: take 195Kg of styrene and add it to the batching kettle, add 15Kg of polystyrene resin, stir for 3 hours, wait for it to fully dissolve, then add 20Kg of solid paraffin, heat up to 60°C and stir for 20min, after it is fully dissolved, pump Add divinylbenzene 35Kg, and add initiator benzoyl peroxide 2Kg, stir 5min, obtain organic phase, standby;

[0039](3) Polymerization operation: put the prepared organic phase into the wat...

Embodiment 3

[0043] Macroporous strongly acidic styrene-based cation exchange resin, the synthesis steps are as follows (the following proportions are calculated based on 1 ton of finished resin):

[0044] (1) Preparation of water phase material: 600Kg of demineralized water is added to the reactor, then 30Kg of industrial salt is added, until it is completely dissolved, 18Kg of polyvinyl alcohol aqueous solution of methylene blue 1g and 1788 (4%) aqueous solution is added, fully stirred Mix and heat up to 58°C for later use;

[0045] (2) Prepare the organic phase: Take 190Kg of styrene and add it to the batching kettle, add 20Kg of polystyrene resin, stir for 3 hours, wait for it to fully dissolve, then add 30Kg of solid paraffin, heat up to 60°C and stir for 20min, after it is fully dissolved, pump Add divinylbenzene 40Kg, and add initiator benzoyl peroxide 3Kg, stir 5min, obtain organic phase, standby;

[0046] (3) Polymerization operation: Put the prepared organic phase into the water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com