Method for preparing VC by ultrasonic induced crystallization on gulonic acid aqueous solution

A technology for inducing crystallization and coronic acid, applied in the direction of organic chemistry, etc., can solve the problems of high waste water treatment cost, high investment cost and operation cost of production line, complicated steps, etc., to improve direct conversion rate, speed up induced crystallization and crystal growth. The effect of a large process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

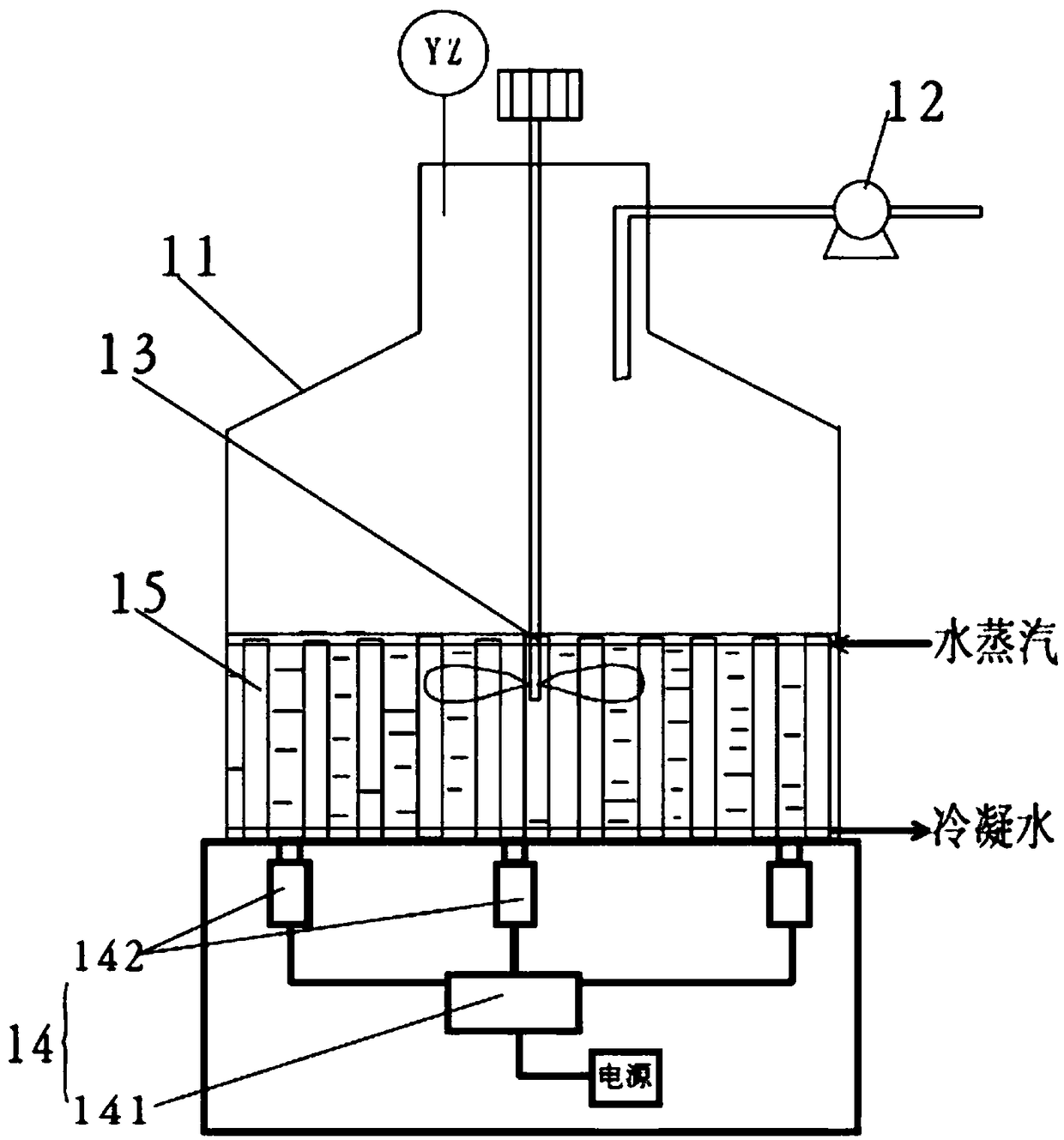

[0033] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

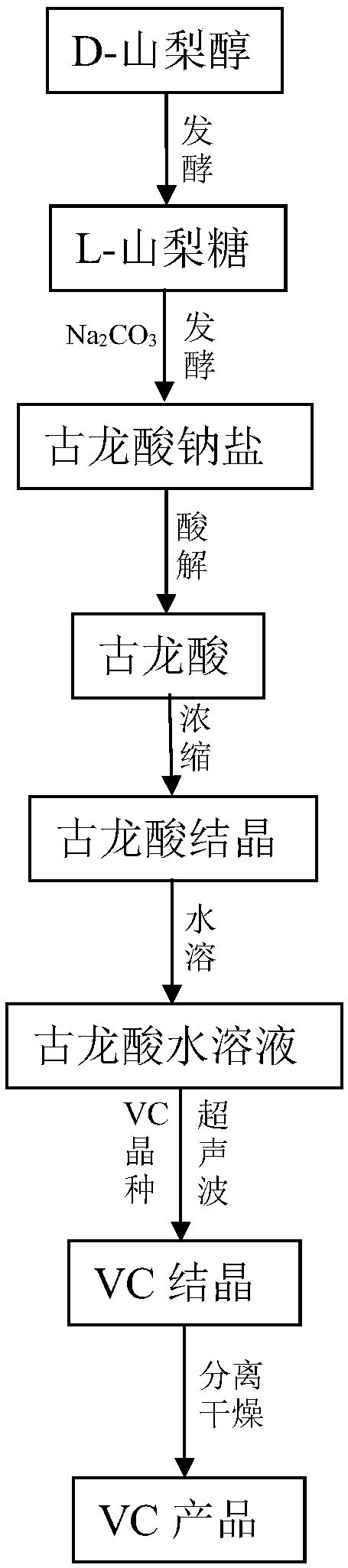

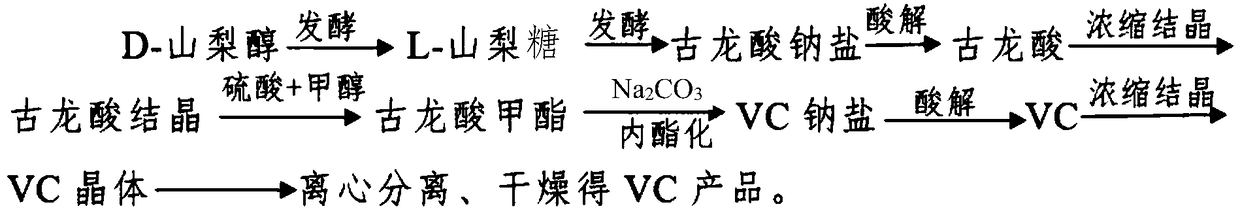

[0034] Such as figure 1 Shown is a flow chart of the method for preparing VC in a preferred embodiment of the present invention. Also use D-sorbitol as raw material, ferment and convert it into L-sorbitol, continue to ferment and react with alkaline sodium salt to convert into sodium guronate; , the solvent was evaporated to obtain gulonic acid crystals. Gulonic acid crystals are dissolved in deionized water, and then an ultrasonic field is applied to the aqueous solution of gulonic acid to induce the direct conversion of gulonic acid into VC crystals by ultrasonic waves. Its reaction process is expressed as:

[0035]

[0036] Finally, the solution is transferred to a centrifugal separation device for centrifugal separation and drying to obtain the VC pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com