Zero discharging treatment system for heat-engine-plant tail-end high-salinity wastewater and working method thereof

A technology of high-salt wastewater and treatment system, applied in gaseous discharge wastewater treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve problems such as concentration of difficult-to-desulfurize wastewater and reduction of boiler efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0018] Example.

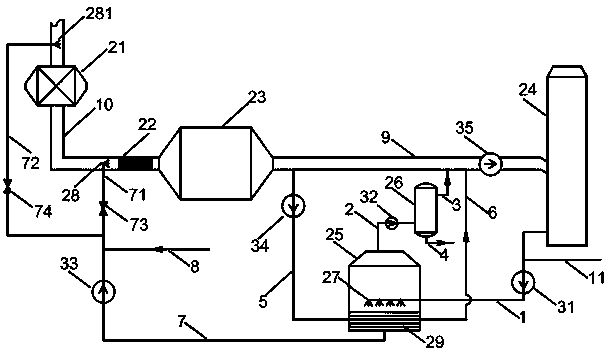

[0019] see figure 1 , a zero-emission treatment system for high-salt wastewater at the end of a thermal power plant, comprising a low-temperature flue gas pipeline 9, a high-temperature flue gas pipeline 10, an air preheater 21, a flue gas cooler 22, a dust collector 23, a desulfurization tower 24, and an induced draft fan 35 Air preheater 21, flue gas cooler 22 and dust collector 23 are arranged on the high-temperature flue gas pipeline 10 successively along the flow direction of flue gas, and one end of dust collector 23 communicates with high-temperature flue gas pipeline 10, and dust collector 23 The other end communicates with the low-temperature flue gas pipeline 9, and the dust collector 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com