Process for preparing calcium chloride by utilizing high-boiling residues generated by silicon tetrachloride rectification via hydrolysis

A technology of silicon tetrachloride and high boilers, which is applied in the field of polysilicon by-product reuse, and can solve the problems of not being effectively treated, environmental hazards, waste of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

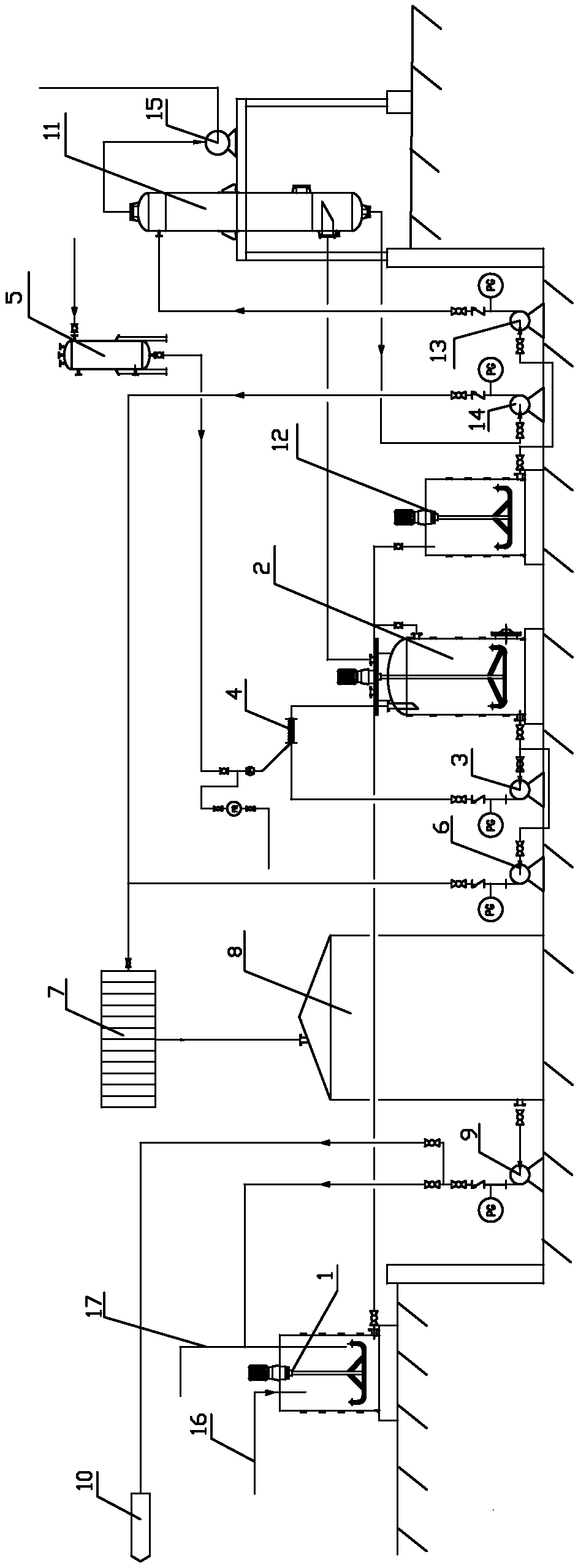

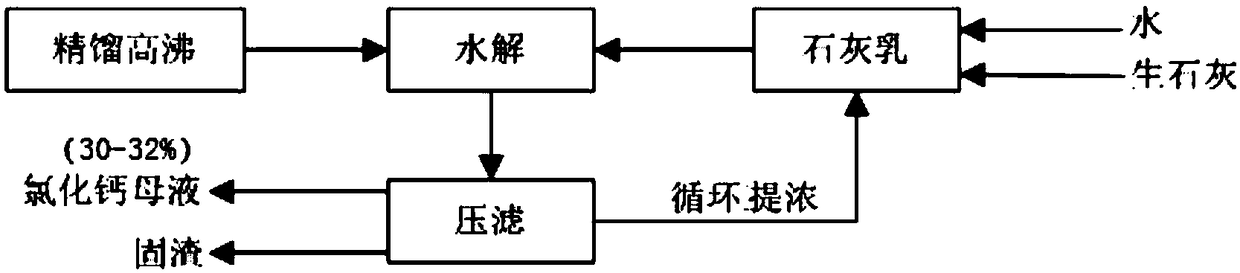

[0025] A process for preparing calcium chloride by hydrolysis of silicon tetrachloride rectification high boilers figure 1 as shown, figure 2 shown), including the following steps:

[0026] (1) Quicklime and water are stirred and reacted in the emulsification reactor 1 according to the mass ratio = 1:5 to form lime milk, and the temperature of the water is controlled at 55°C. Water is added through the water inlet 17, and quicklime is added through the inlet 16 for quicklime.

[0027] (2) Feed milk of lime into the high boiler hydrolysis reaction kettle 2 from the lime milk feeding port on the upper part of the high boiler hydrolysis reaction kettle. The material flows out from the outlet, and is transported to the pipeline mixer 4 through the hydrolysis circulating pump 3 to mix with the high boiling substances from the high boiling substance metering tank 5 for primary hydrolysis reaction. The liquid delivery rate of the hydrolysis circulating pump is 500L / h, which comes ...

Embodiment 2

[0031] A process for preparing calcium chloride by hydrolysis of silicon tetrachloride rectification high boilers figure 1 as shown, figure 2 shown), including the following steps:

[0032] (1) Quicklime and water are stirred and reacted in the emulsification reactor 1 according to the mass ratio = 1: 10 to form lime milk, and the temperature of the water is controlled at 65°C. Water is added through the water inlet 17, and quicklime is added through the inlet 16 for quicklime.

[0033] (2) Feed milk of lime into the high boiler hydrolysis reaction kettle 2 from the lime milk feeding port on the upper part of the high boiler hydrolysis reaction kettle. The material flows out of the outlet, and is transported to the pipeline mixer 4 through the hydrolysis circulation pump 3 to mix with the high boiling substances from the high boiling substance metering tank 5 to undergo a primary hydrolysis reaction. The liquid delivery rate of the hydrolysis circulation pump is 600L / h, from ...

Embodiment 3

[0037] A process for preparing calcium chloride by hydrolysis of silicon tetrachloride rectification high boilers figure 1 as shown, figure 2 shown), including the following steps:

[0038] (1) Quicklime and water are stirred and reacted in the emulsification reactor 1 according to the mass ratio = 1:8 to form lime milk, and the temperature of the water is controlled at 60°C. Water is added through the water inlet 17, and quicklime is added through the inlet 16 for quicklime.

[0039] (2) Feed milk of lime into the high boiler hydrolysis reaction kettle 2 from the lime milk feeding port on the upper part of the high boiler hydrolysis reaction kettle. The material flows out from the outlet, and is transported to the pipeline mixer 4 through the hydrolysis circulation pump 3 to mix with the high boiling substances from the high boiling substance metering tank 5 to undergo primary hydrolysis reaction. The liquid delivery rate of the hydrolysis circulation pump is 550L / h, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com