Automotive lightweight rubber damping driving shaft supporting bearing manufacturing method

A technology of rubber shock absorption and supporting bearings, which is applied in the field of auto parts manufacturing, can solve the problems of reducing the performance and service life of engineering plastics, the complex metal structure of plastic structural parts, and the high cost of rubber molds, so as to reduce processing costs and improve mold structure design. Effects of simplification, avoidance of degradation or shape change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

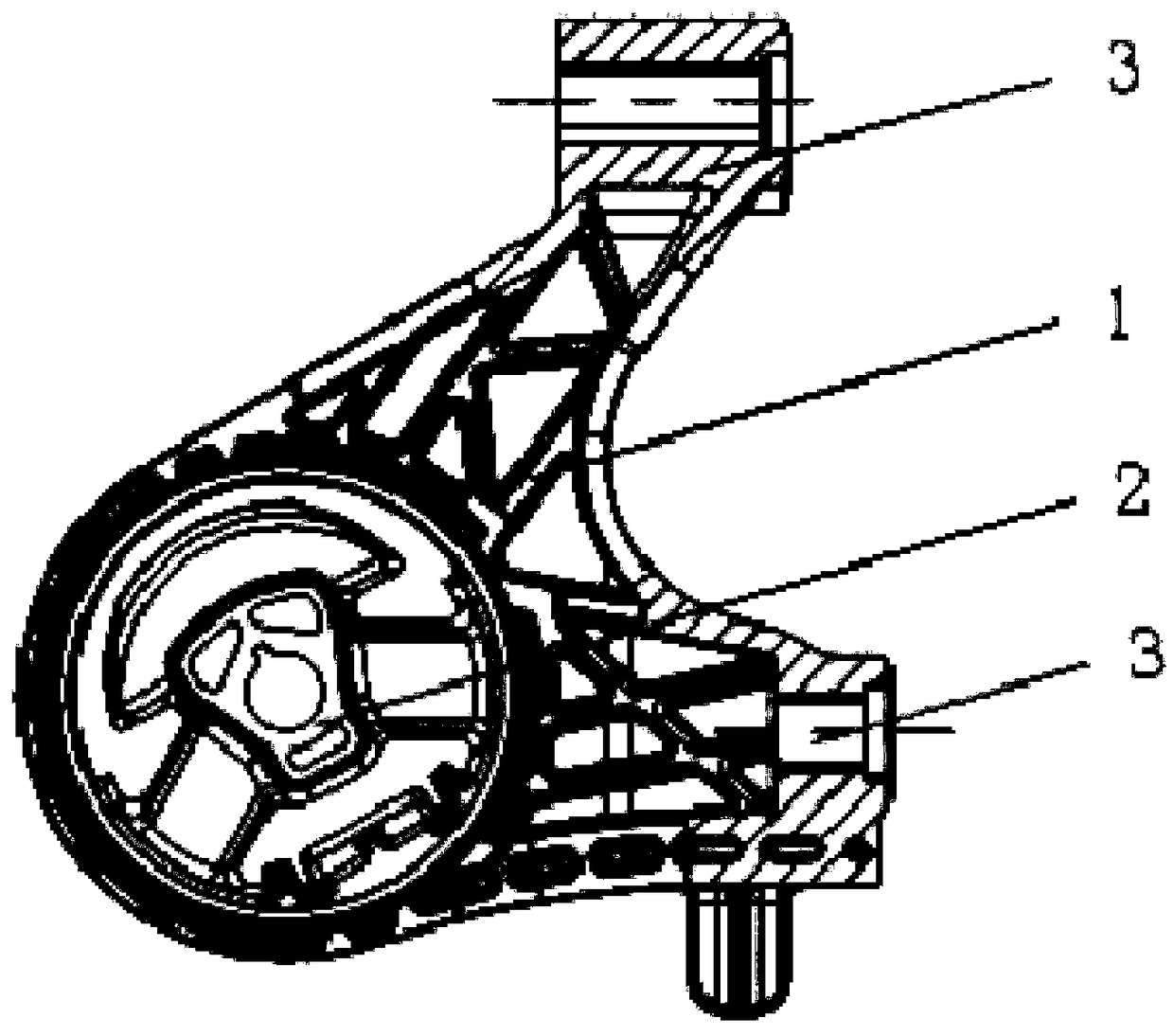

[0030] A method for manufacturing lightweight rubber shock-absorbing drive shaft support bearings for automobiles, characterized in that the rubber shock-absorber drive shaft support bearings are composed of a main spring 2 made of rubber, a bracket 1 made of plastic, and a metal frame. The insert 3 is composed of, and the described manufacturing method comprises the following processing steps:

[0031] (1) Vulcanization: Put the main spring into the vulcanization mold for vulcanization treatment, apply a vulcanization pressure of 10-30MPa to the vulcanization mold, control the vulcanization treatment temperature to 120°C, and set the vulcanization treatment time to 30 minutes;

[0032] In this step, the material of the insert 3 is aluminum alloy, and the mixed rubber material used for the main spring 2 is prepared by the traditional mixing process, and the components of the mixed rubber are weighed: 100g natural rubber SVR3L, 5g zinc oxide ZnO, 1.5g Stearic acid, 1g microcrys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com