A kind of glue material preparation method

A technology of glue and glue, which is applied in the field of glue material preparation, can solve the problems of non-sticky adhesive, poor fluidity and activity performance, insufficient crushing, etc., and achieve the effect of increasing friction and shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

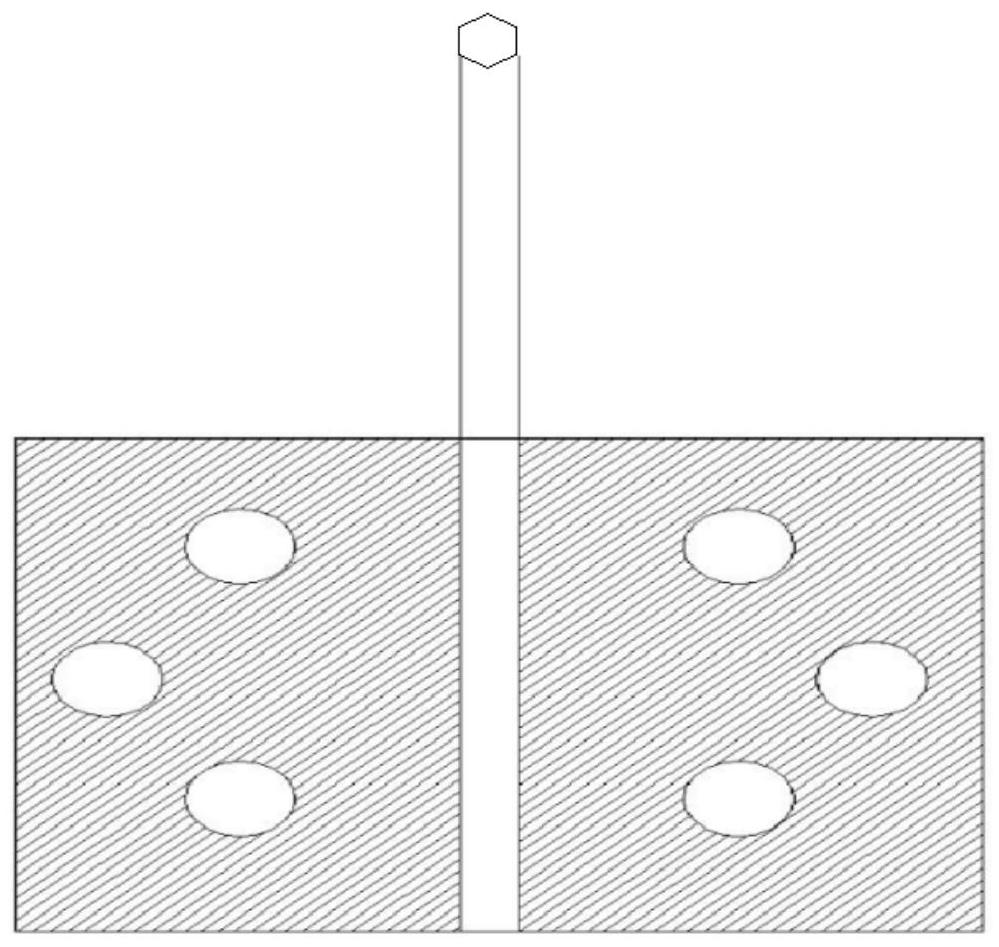

[0044]Such as figure 1 This embodiment designs a special stirring rod in the preparation method of the mortar material. The non-forced transmission part of the stirring rod is designed as a cylinder, and the stressed part is designed as two blades to improve shear force and friction. Installed vertically with the cylinder, the rotation of the blade can drive the mixing of the rubber material in a large range during the rotation and stirring. There are regular and symmetrical round holes in different positions on the blade. The end of the stirring rod is designed with a hexagonal outer interface, and a matching hexagonal inner interface is connected to the connecting shaft of the stirring motor, so that the stirring rod can be easily installed on and removed from the stirring motor Set aside for hand stirring.

Embodiment 2

[0046] This embodiment designs a special stirring rod in the preparation method of the mortar material. The difference from the embodiment 1 lies in that the irregular shape is designed on the blade of the stirring rod, and the graphics on both sides of the blade are asymmetrical.

Embodiment 3

[0048] What this embodiment designs is a kind of special-purpose stirring bar in the mortar material preparation method, and the difference with embodiment 1 is that it designs the blade that links to each other with the cylinder of stirring bar as 5 pieces, makes the mortar material in the stirring process Stir more evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com