A high-precision automatic docking device and its docking method

An automatic docking and high-precision technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low efficiency, large resistance at the moment of starting, long docking time, etc., and achieves convenient use, high degree of automation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

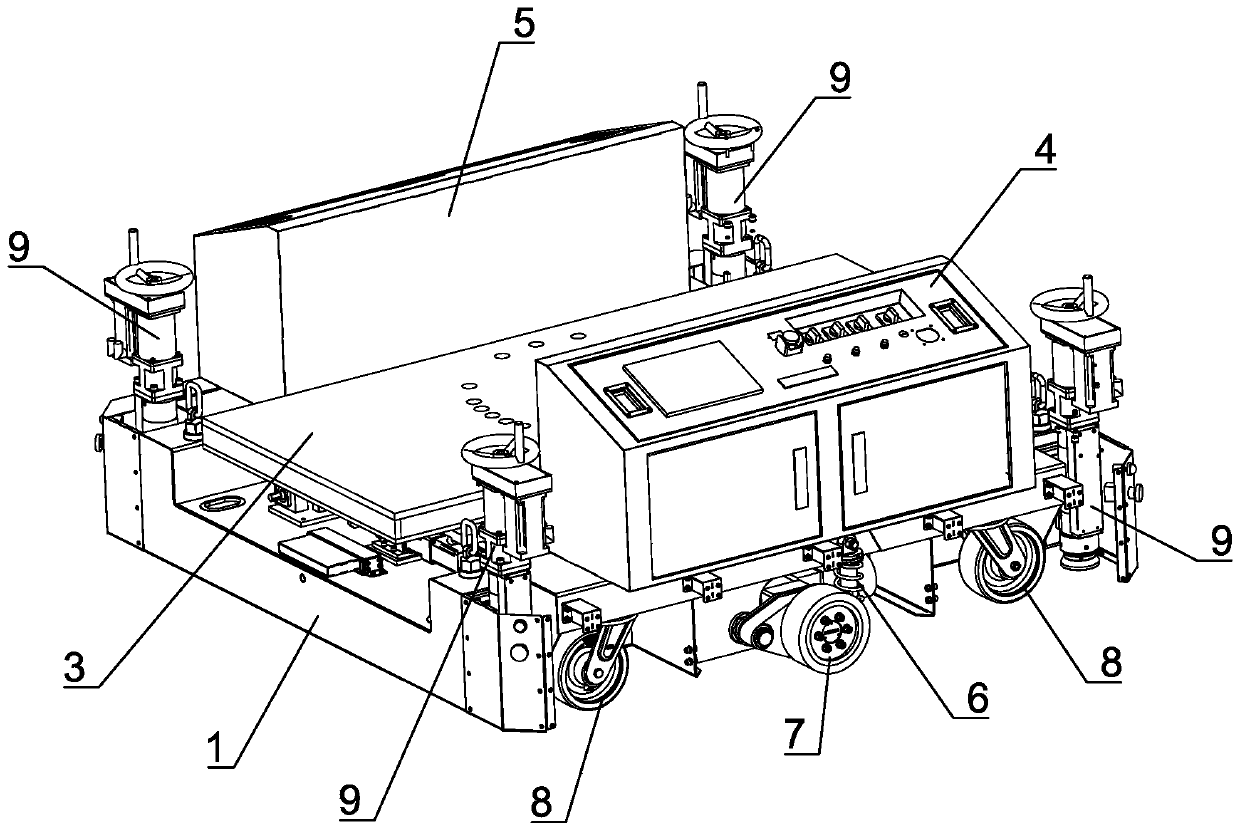

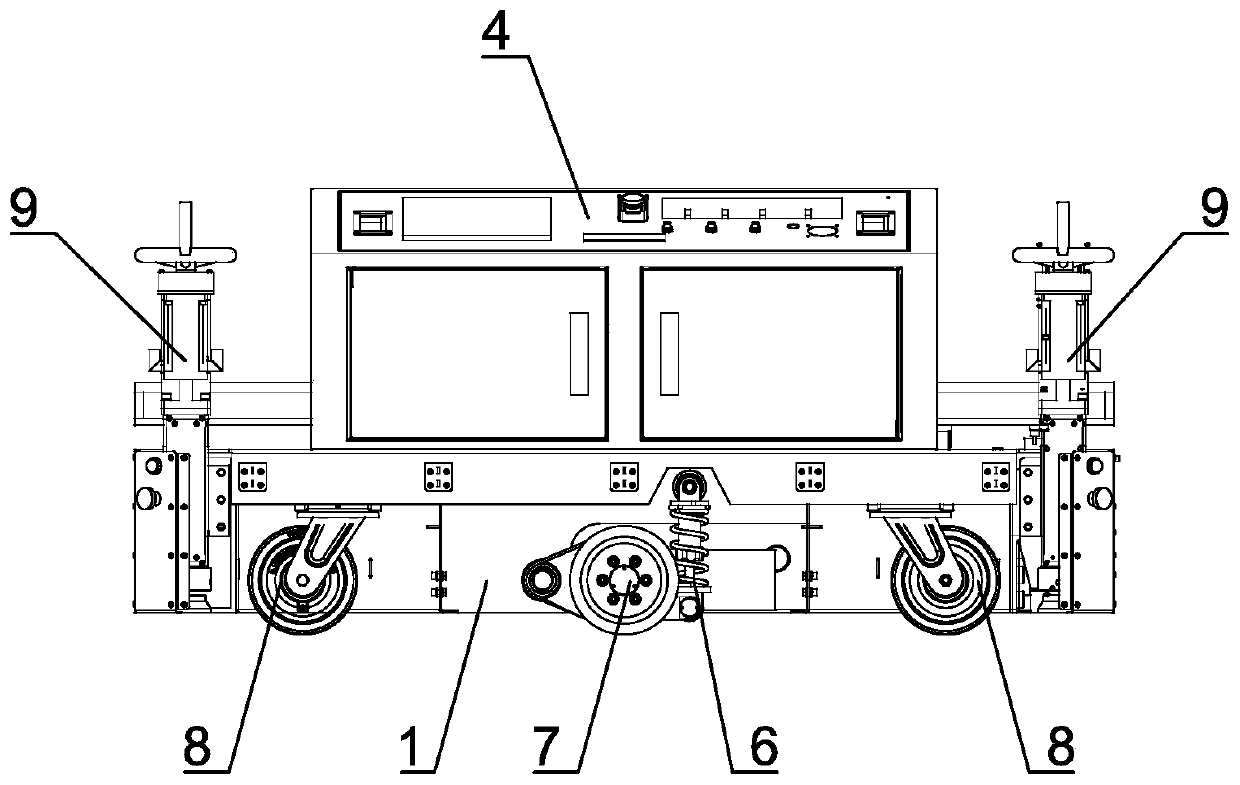

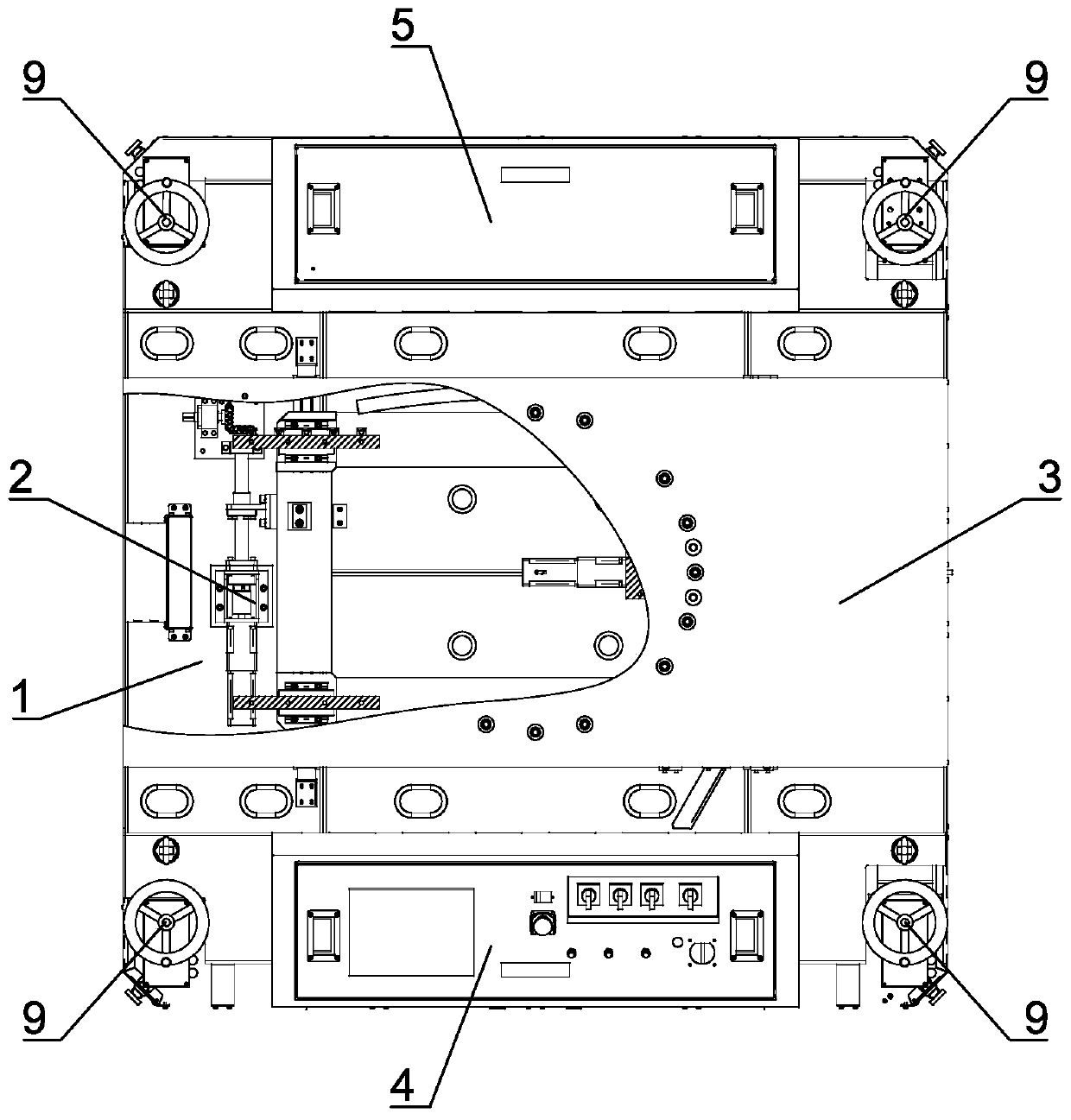

[0029] Such as Figure 1 to Figure 4Shown is a specific embodiment of a high-precision automatic docking device of the present invention, including a chassis 1 and a slewing support platform 3 mounted on the chassis 1 through a set of horizontal and vertical guide rails 2 . The base frame 1 is provided with an electric control cabinet 4 and a battery cabinet 5 correspondingly on the left and right sides of the slewing support platform 3 , and a control system is provided in the electric control cabinet 4 . At the bottom of the underframe 1, drive wheel assemblies 7 are installed respectively through two groups of suspension damping mechanisms 6, and the bottom of the underframe 1 is provided with left and right symmetrical driven wheel assemblies 8 at the front and back sides of the drive wheel assemblies 7. Four corners of the underframe 1 are respectively provided with liftable outrigger assemblies 9 . A posture detection alarm system (not shown in the figure) and a trackin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com