Vertical vortex powder selector adopting lateral air feeding, powder selection method implemented by vertical vortex powder selector, and application of vertical vortex powder selector

A powder separator and side air inlet technology, which is applied in the direction of centrifuges, swirl devices, and devices whose axial direction can be reversed, can solve the problem of stable equipment life and internal components of powder separators that affect system operation. Erosion wear, powder separator equipment structure wear and other problems, to achieve the effect of reducing the height of process layout, reasonable structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

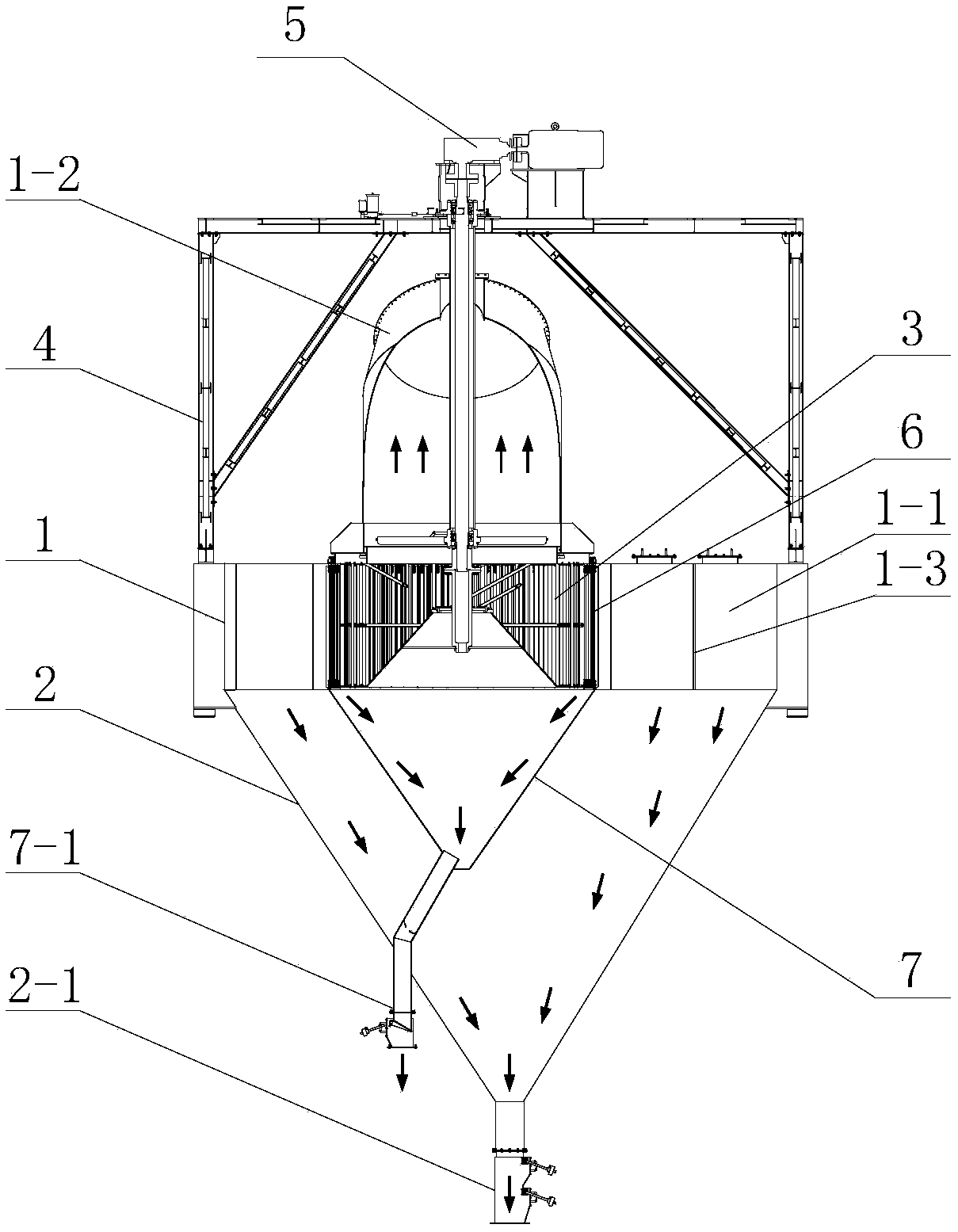

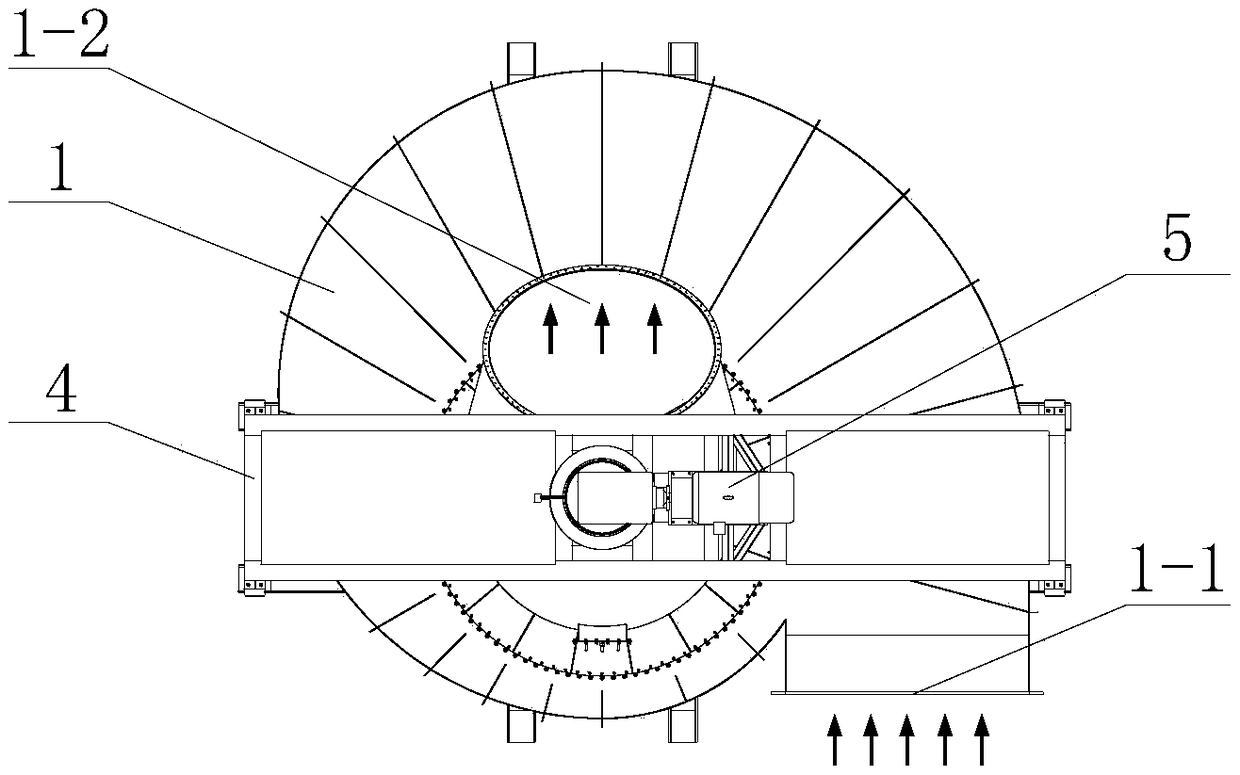

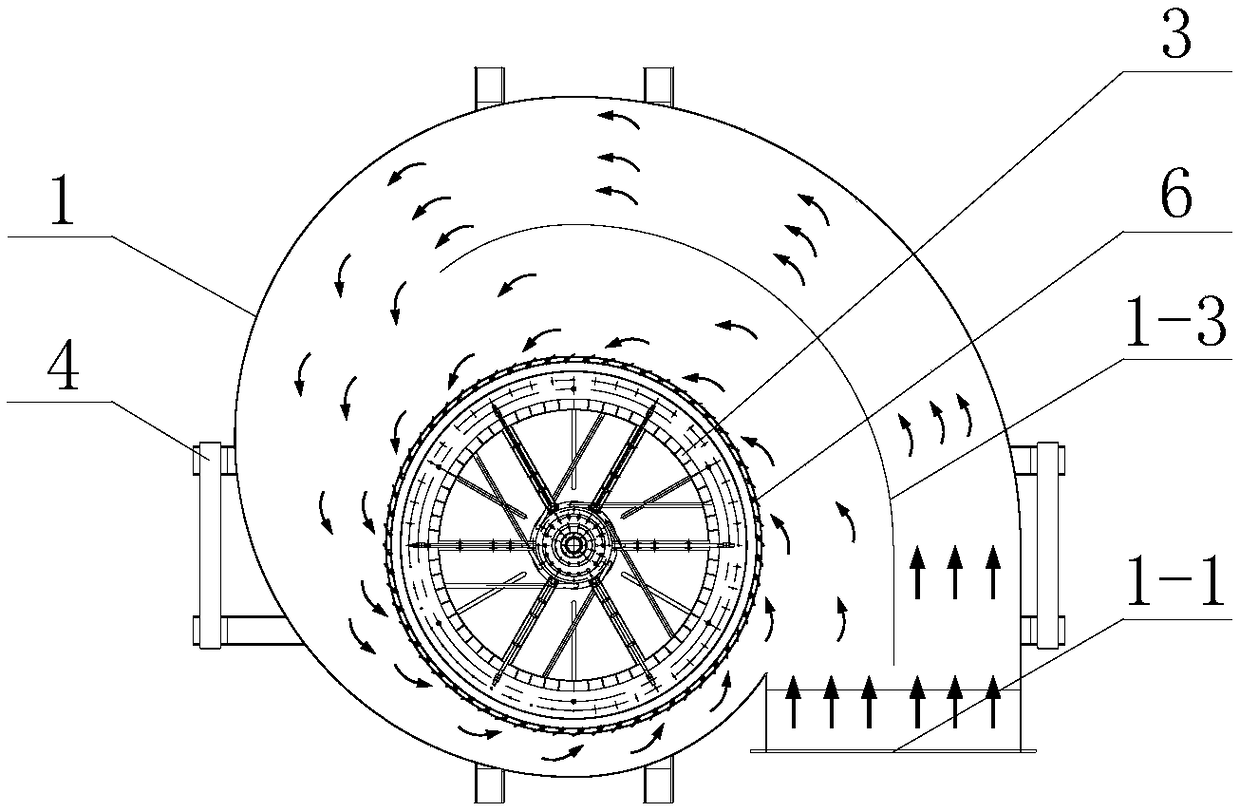

[0032] like Figure 1 to Figure 3 As shown, the present invention provides a kind of vertical vortex powder separator with side air inlet, comprising a volute 1 arranged at the top and a cone 2 arranged at the bottom; the volute 1 is horizontally arranged, and the volute 1 The open end is an air inlet 1-1; an air outlet 1-2 connected to a dust collection device is provided on the upper part of the volute 1; a cage-shaped rotor 3 is arranged inside the volute 1, and the air outlet 1-2 is arranged above the shaped rotor 3;

[0033] A supporting device 4 is provided above the volute; the supporting device 4 is provided with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com