Self-adaptive wind direction and natural draft smoke exhaust device that can adjust resistance in linkage

A self-adaptive technology for exhaust and smoke extraction, which is applied to exhaust gas devices, induced drafts, and combustion product treatment. The effect of wind, reducing bearing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

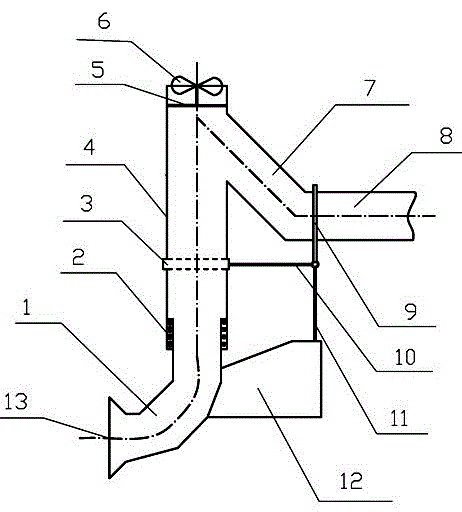

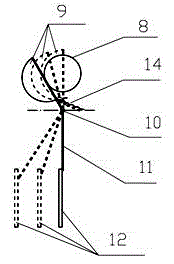

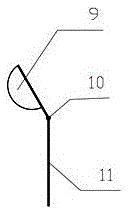

[0012] Such as figure 1 As shown, a natural draft smoke exhaust device that adapts to the wind direction and can adjust the resistance in linkage, it includes an air inlet pipe 1 that rotates with the wind direction, and a trumpet-shaped air inlet 13 is arranged at the lower end of the air inlet pipe 1, and the air inlet The upper end of the pipe 1 is socketed together with the lower end of the vertical pipe 4 through the bearing 2 and makes the air inlet pipe 1 pivot relative to the vertical pipe 4; the wall of the air inlet pipe 1 on the opposite side of the air inlet 13 is provided with a vertical wind fin 12. A fixed support 3 is provided in the middle of the vertical pipe 4, a support rod 10 is provided on the fixed support 3, a swing rod 11 is hinged at the end of the support rod 10, a return spring 14 is arranged at the hinge, and the upper end of the swing rod 11 is fixed with a Flue gate 9, return spring 14 resets the flue gate 9 to the initial position of half openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com