Purifying device and purifying method

A purification device and fluidized bed technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problem of high energy consumption, and achieve the effect of reducing energy consumption and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

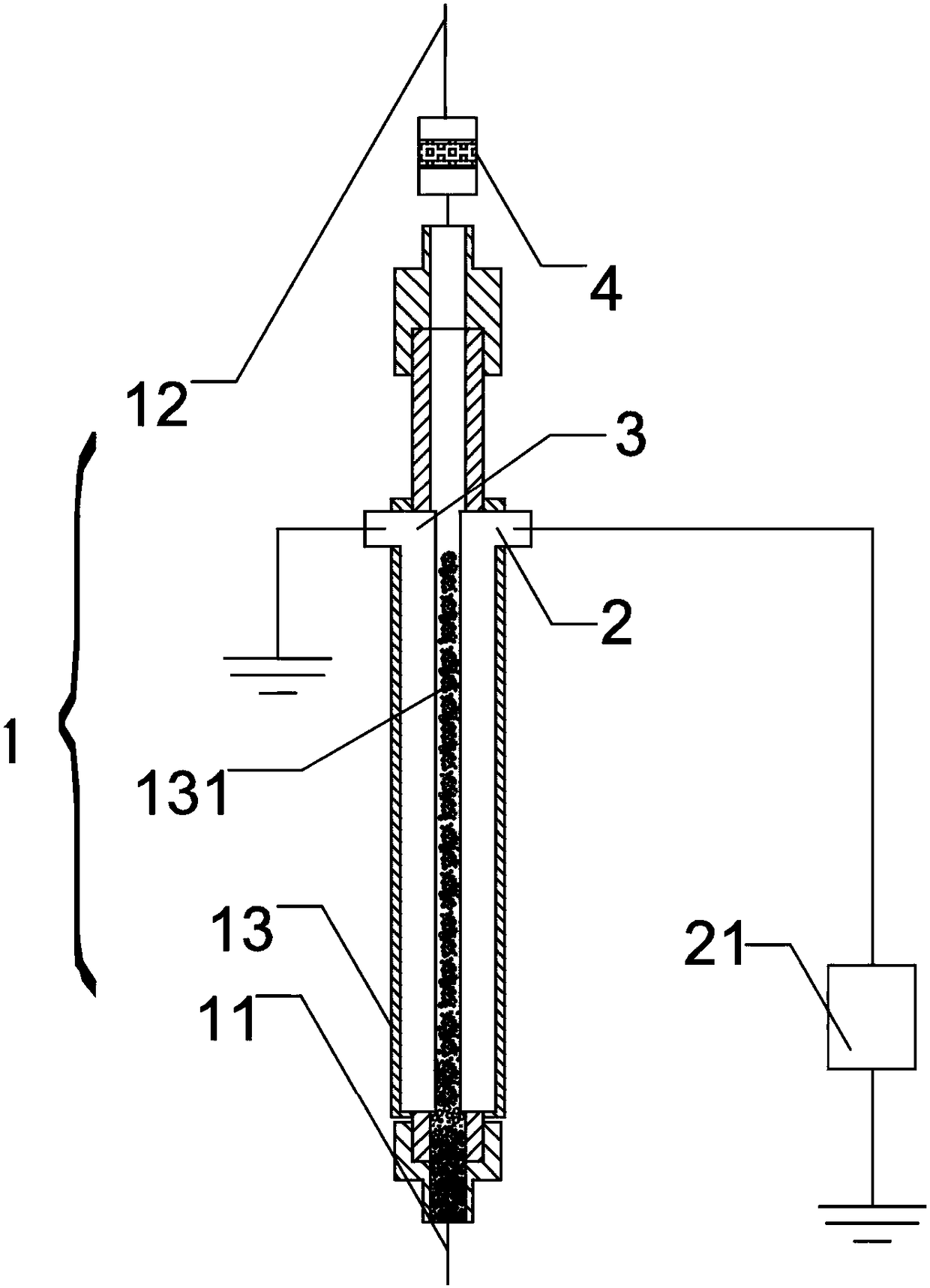

[0054] The first embodiment of the present invention provides a purification device, see figure 1 shown, including:

[0055] Fluidized bed 1, fluidized bed 1 comprises hollow reaction tube 13 and the gas inlet 11 that is arranged on reaction tube 13 two ends, gas outlet 12, is provided with biomass conductive carbon particle 131 in reaction tube 13, biomass conductive carbon particle 131 Can be in a fluidized state under the action of air flow;

[0056] The purification device also includes a high-voltage electrode 2 and a low-voltage electrode 3 respectively arranged on both sides of the fluidized bed 1;

[0057] The organic pollutant gas enters the reaction tube 13, and a potential difference is formed between the high-voltage electrode 2 and the low-voltage electrode 3, which breaks down the biomass conductive carbon particles 131 in a fluidized state and forms a discharge to degrade the organic pollutant gas.

[0058] Wherein, the reaction tube 13 can be a circular insul...

Embodiment approach 2

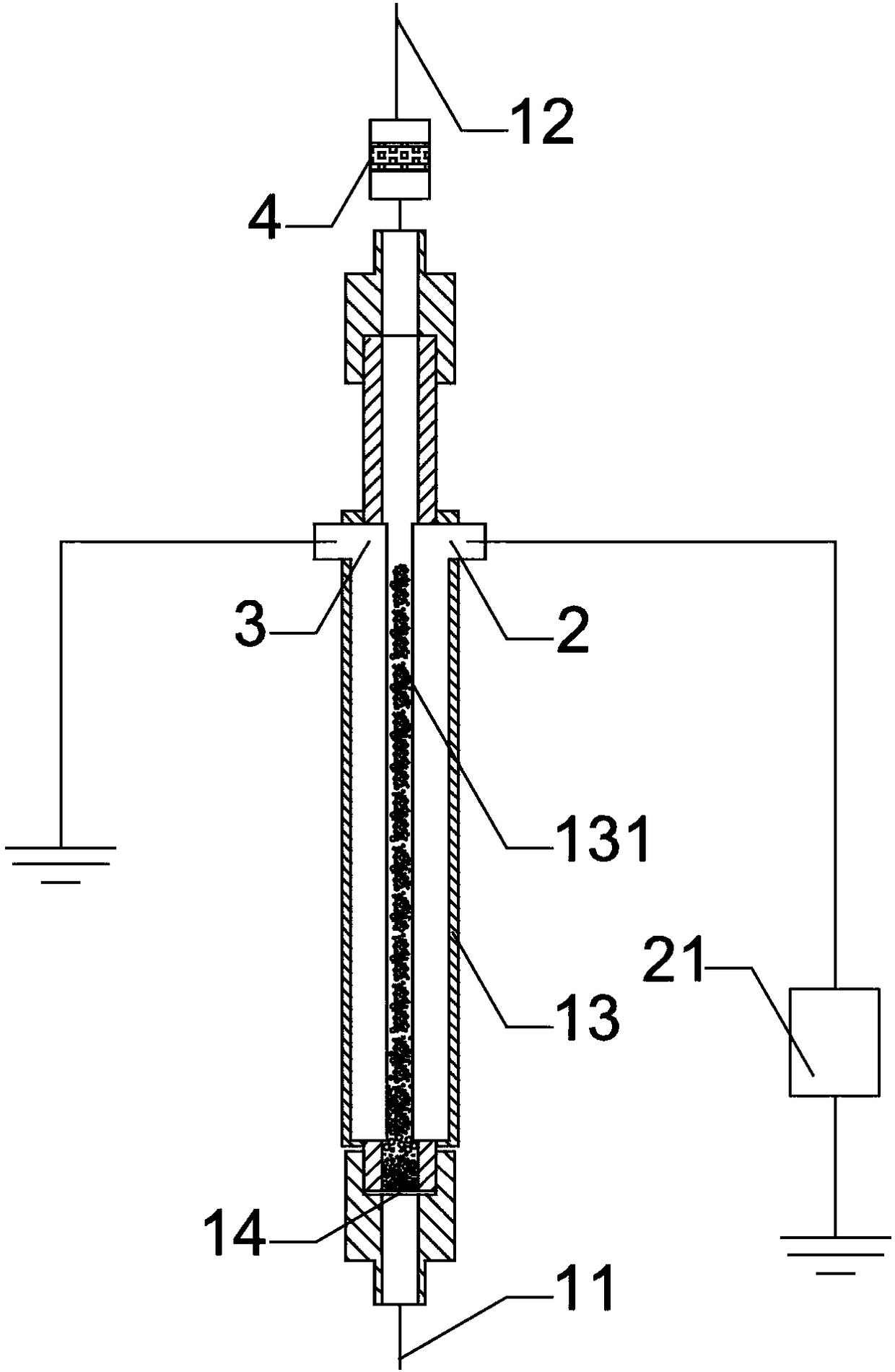

[0064] A second embodiment of the present invention provides a purification device. The second embodiment is a further improvement of the first embodiment, the main improvement is that, in the second embodiment of the present invention, see figure 2 As shown, the fluidized bed 1 also includes a gas flow distribution plate 14 arranged at one end of the reaction tube 13 close to the gas inlet 11, and a plurality of through holes are distributed on the gas flow distribution plate 14, and the aperture of the through holes is smaller than that of the biomass conductive carbon particles 131. particle size.

[0065] In this embodiment, the airflow distribution plate 14 can be made of insulating and corrosion-resistant materials, such as polytetrafluoroethylene, ceramics, etc., so that the insulating and corrosion-resistant materials can prolong the service life of the airflow distribution plate 14 as much as possible. The through holes provided in the gas flow distribution plate 14...

Embodiment approach 3

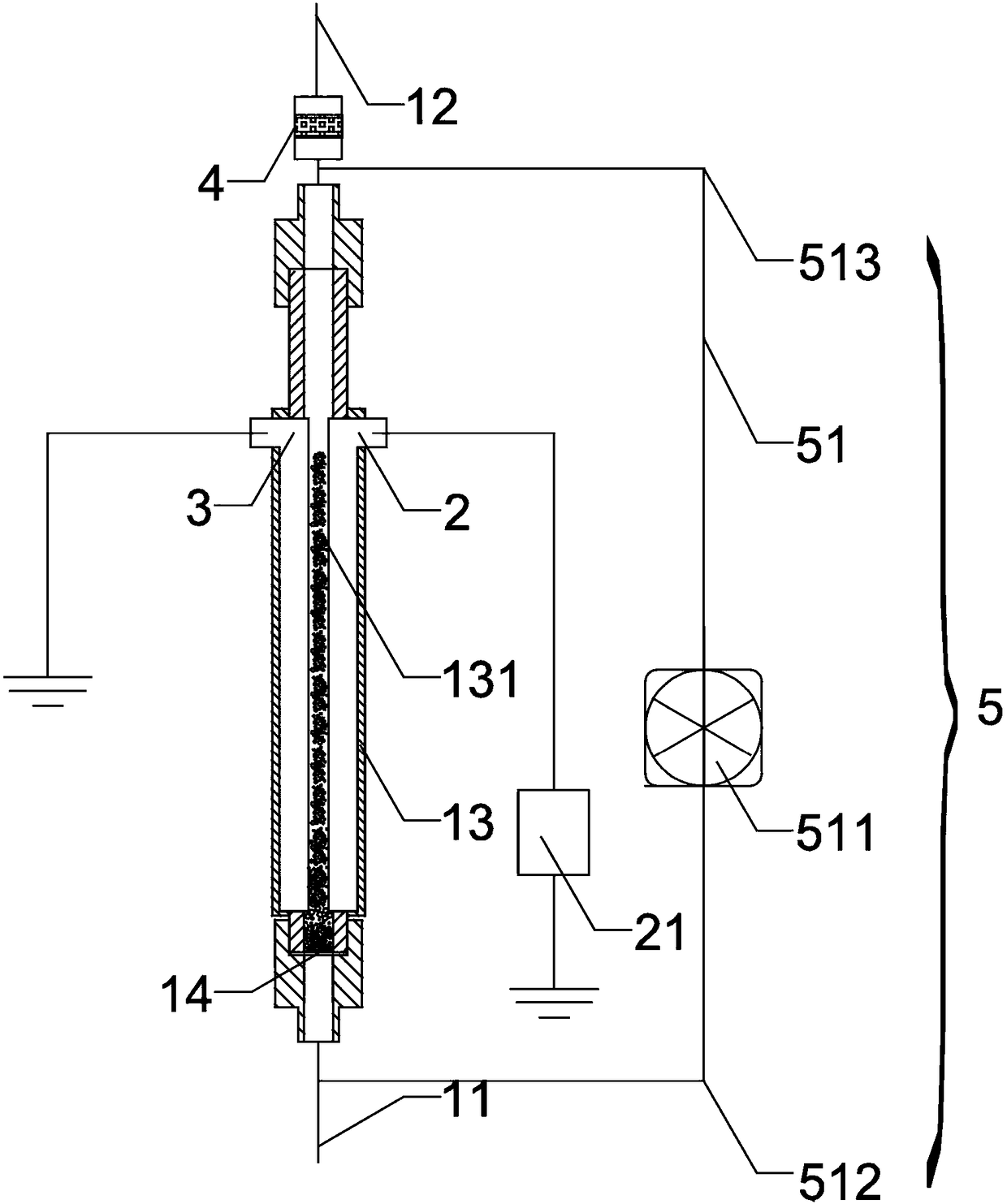

[0067] A third embodiment of the present invention provides a purification device. The third embodiment is a further improvement of the first embodiment, the main improvement is that, in the third embodiment of the present invention, see image 3 As shown, the purification unit also includes:

[0068] The circulation mechanism 5, the circulation mechanism 5 includes a circulation channel 51 connected to the gas inlet 11 and the gas outlet 12 at both ends and a circulation fan 511 arranged on the circulation channel 51, and the circulation channel 51 is provided with a circulation inlet 512 and a circulation outlet 513 ;

[0069] The background gas circulates in the circulation channel 51 and the reaction tube 13 driven by the circulation fan 511, and the biomass conductive carbon particles 131 are in a fluidized state under the action of the background gas;

[0070] The organic pollutant gas enters the circulation channel 51 through the circulation inlet 512 , circulates in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com