Intelligent sign language perceptual glove and a manufacturing process thereof

A manufacturing process and sign language technology, applied in the field of intelligent sign language sensing gloves and its manufacturing process, can solve the problems of weak sensitivity, poor accuracy, and poor consistency, and achieve the effect of strong sensitivity, high accuracy, and good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

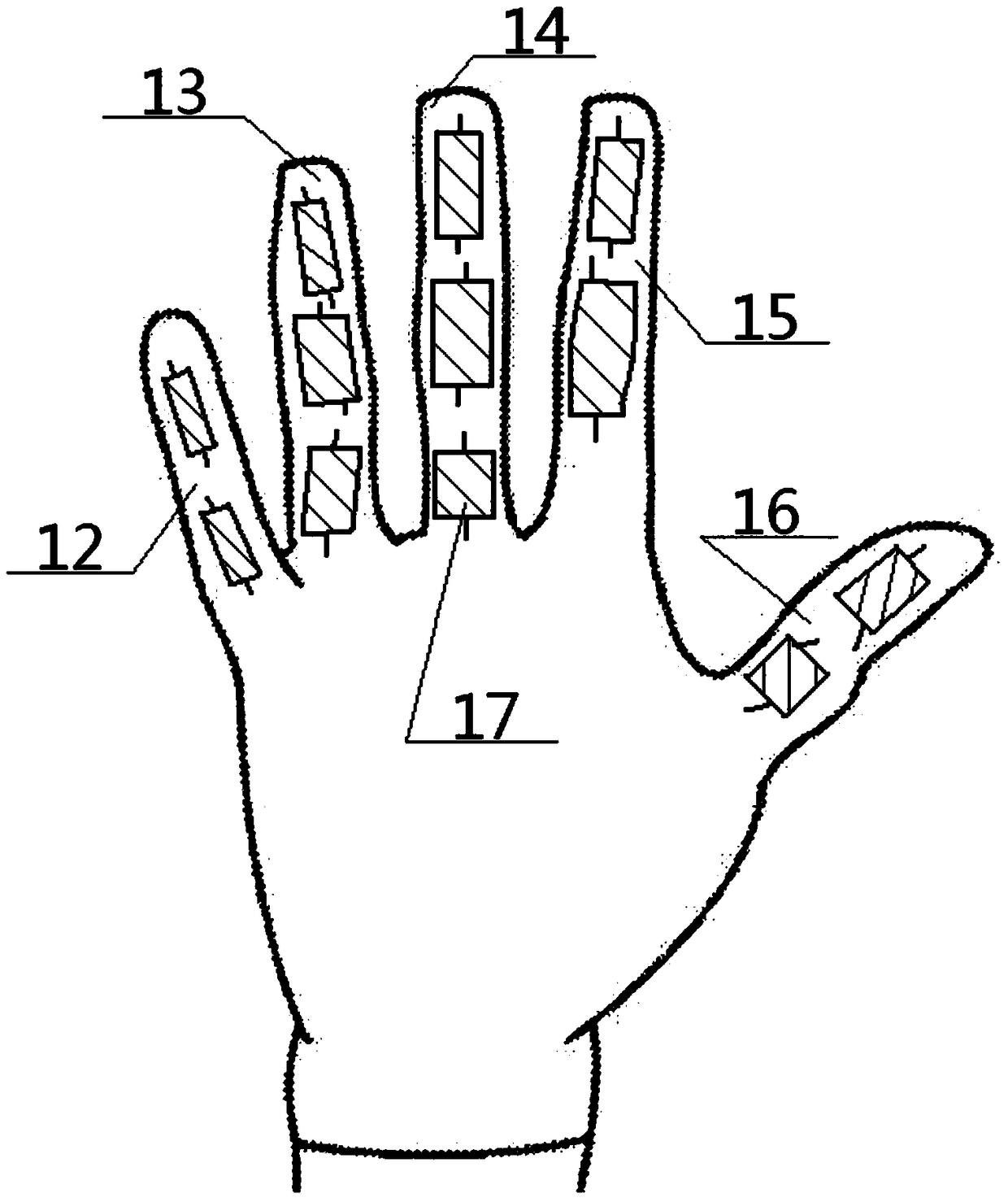

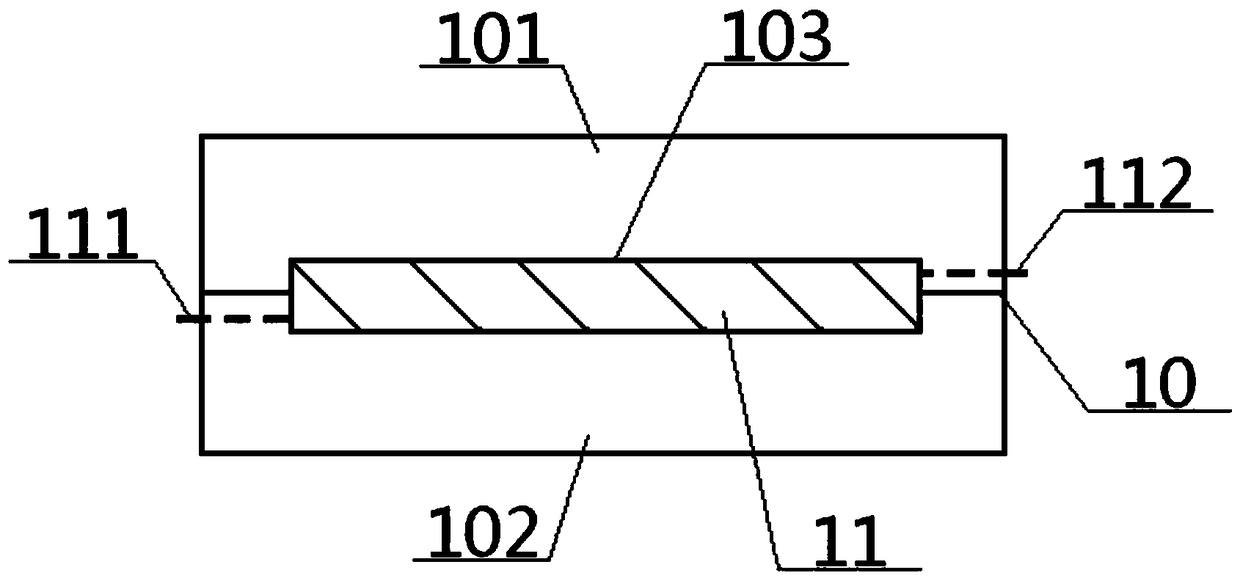

[0052] A smart sign language perception glove, comprising a finger sleeve and a plurality of sensors set thereon, and the sensors are connected with external monitoring equipment for signal; the finger sleeve includes little finger sleeve 12, ring finger sleeve 13, middle finger sleeve 14, index finger sleeve 15 and The thumb cover 16, the sensor is a flexible sensor 17, the little finger cover 12, the ring finger cover 13, the middle finger cover 14, the index finger cover 15, and the thumb cover 16 are all provided with at least one flexible sensor 17, the flexible sensor 17 including The outer covering layer 10 and the inner conductor 11 inside. The outer covering layer 10 includes an upper covering layer 101 and a lower covering layer 102. The bottom surface of the upper covering layer 101 is connected with the top surface of the lower covering layer 102. The upper covering layer 101 , The middle part of the junction of the lower covering layer 102 is provided with a body ca...

Embodiment 2

[0057] The basic content is the same as Example 1, the difference is:

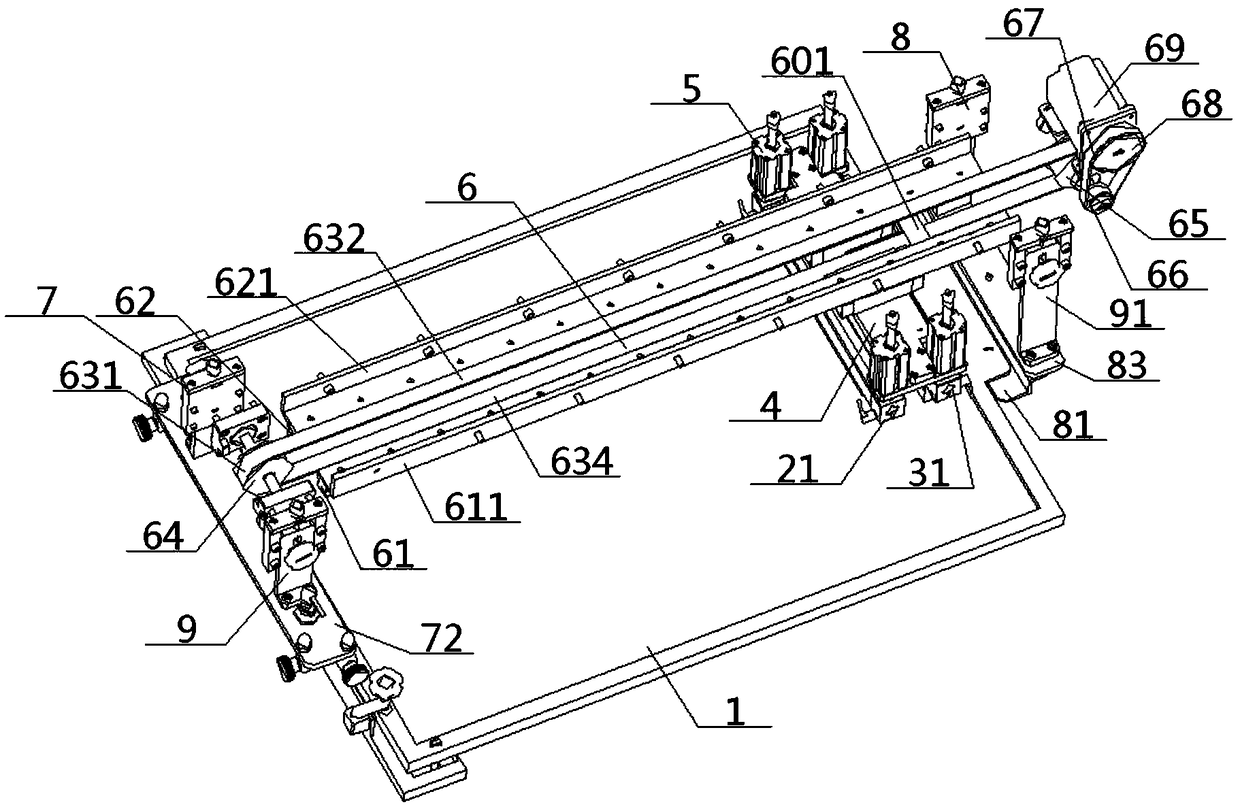

[0058] The first scraper 2 and the second scraper 3 connected to the scraper seat plate 4 are arranged directly above the screen frame 1. The left side of the screen frame 1 is connected to the bottom of the left vertical plate 71, and the left vertical plate 71 The top is vertically connected to the inner side of the left horizontal plate 72, the top surface of the left horizontal plate 72 is connected to the bottom end of the left longitudinal adjusting device 7 of the screen frame, and the right side of the screen frame 1 is connected to the lower right horizontal plate 81 The top surface is superimposed and connected, the right side of the right lower horizontal plate 81 is vertically connected to the bottom of the right vertical plate 82, the top of the right vertical plate 82 is vertically connected to the left side of the right upper horizontal plate 83, and the top surface of the right upper horizontal...

Embodiment 3

[0061] The basic content is the same as in Example 2, the difference is:

[0062] The top of the scraper seat plate 4 is connected with a longitudinal displacement device 5, which includes a longitudinal cylinder 51 and a longitudinal cylinder B 52. The bottoms of the longitudinal cylinder A 51 and the longitudinal cylinder B 52 are connected to the scraper seat plate. 4 is connected to the top surface, the output end of the first longitudinal cylinder 51 passes through the scraper seat plate 4, and then passes through the first knife seat 21, the first clamp portion 23 and then is connected to the top of the first scraper 2, and the output end of the second longitudinal cylinder 52 penetrates After passing through the scraper seat plate 4, it is connected to the top of the second scraper 3 through the second knife holder 31 and the second clamping knife part 33 in turn. The first scraper 2 is located on the left side of the second scraper 3, and the first knife seat 21 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com