Semi-factory pond internal circulation culture system

A breeding system and internal circulation technology, applied in the field of semi-factory pond internal circulation breeding system, can solve the problems of easy floating out of the feeding area, low oxygenation efficiency of the breeding unit, and affecting the normal growth of fish, so as to improve the dissolved oxygen in the water and push water effect, solve the low efficiency of oxygen increase, and improve the effect of dissolved oxygen level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

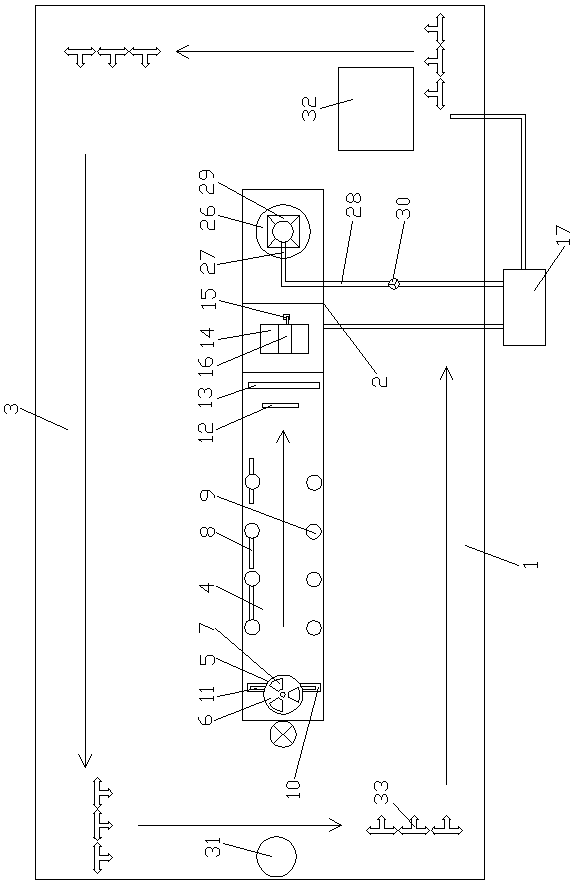

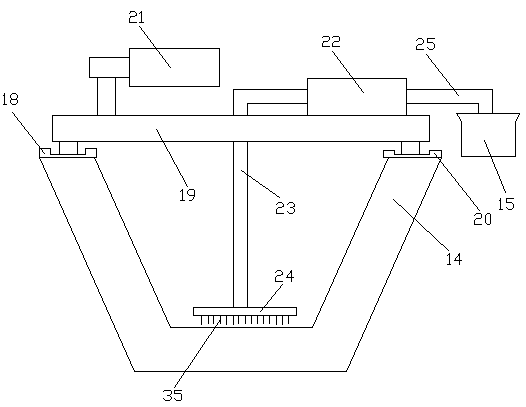

[0057] A semi-industrial pond circulating aquaculture system, comprising a breeding unit 1, a sewage unit 2 and a water purification unit 3. The water outlet of the breeding unit 1 is connected to the water inlet of the sewage unit 2, and the water outlet of the sewage unit 2 is connected to The water inlet of the water purification unit 3 is connected, and the water outlet of the water purification unit 3 is connected with the water inlet of the breeding unit 1;

[0058] The aquaculture unit 1 includes a flowing water tank 4, an aeration and oxygenation device fixed at the front end of the water inlet of the flowing water tank 4, a submerged air stripper 5 arranged in the flowing water tank 4, a primary auxiliary aeration device, and a secondary auxiliary An aeration device, an anti-dead-water zone device, and a material blocking device, the dead-water preventing device is located at the front end of the flowing water tank 4, the material blocking device is located at the back en...

Embodiment 2

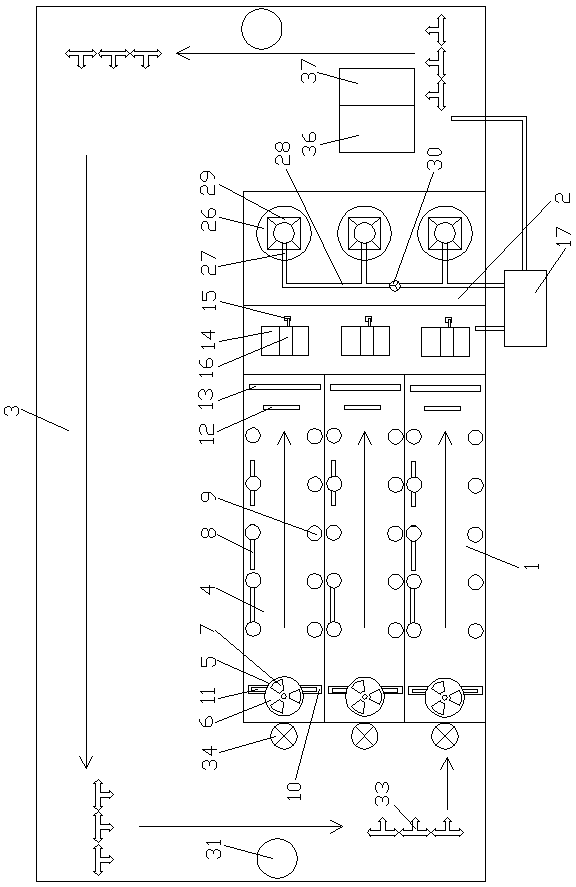

[0063] A semi-industrial pond circulating aquaculture system, comprising a breeding unit 1, a sewage unit 2 and a water purification unit 3. The water outlet of the breeding unit 1 is connected to the water inlet of the sewage unit 2, and the water outlet of the sewage unit 2 is connected to The water inlet of the water purification unit 3 is connected, and the water outlet of the water purification unit 3 is connected with the water inlet of the breeding unit 1;

[0064] The aquaculture unit 1 includes a flowing water tank 4, an aeration and oxygenation device fixed at the front end of the water inlet of the flowing water tank 4, a submerged air stripper 5 arranged in the flowing water tank 4, a primary auxiliary aeration device, and a secondary auxiliary An aeration device, an anti-dead-water zone device, and a material blocking device, the dead-water preventing device is located at the front end of the flowing water tank 4, the material blocking device is located at the back en...

Embodiment 3

[0072] A semi-industrial pond circulating aquaculture system, comprising a breeding unit 1, a sewage unit 2 and a water purification unit 3. The water outlet of the breeding unit 1 is connected to the water inlet of the sewage unit 2, and the water outlet of the sewage unit 2 is connected to The water inlet of the water purification unit 3 is connected, and the water outlet of the water purification unit 3 is connected with the water inlet of the breeding unit 1;

[0073] The aquaculture unit 1 includes a flowing water tank 4, an aeration and oxygenation device fixed at the front end of the water inlet of the flowing water tank 4, a submerged air stripper 5 arranged in the flowing water tank 4, a primary auxiliary aeration device, and a secondary auxiliary An aeration device, an anti-dead-water zone device, and a material blocking device, the dead-water preventing device is located at the front end of the flowing water tank 4, the material blocking device is located at the back en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com