Strawberry elevated cultivation device

A technology for elevated cultivation and strawberry, applied in the field of strawberry elevated cultivation devices, can solve the problems of restricting the promotion and popularization of three-dimensional cultivation technology, the influence of cultivated product quality and yield, and the existence of shading in three-dimensional multi-layer cultivation, so as to achieve full utilization of space and illumination, The effect of avoiding the occurrence of diseases and ensuring the uniformity of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific examples, further illustrate the present invention, the examples are implemented under the premise of the technical solutions of the present invention, it should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

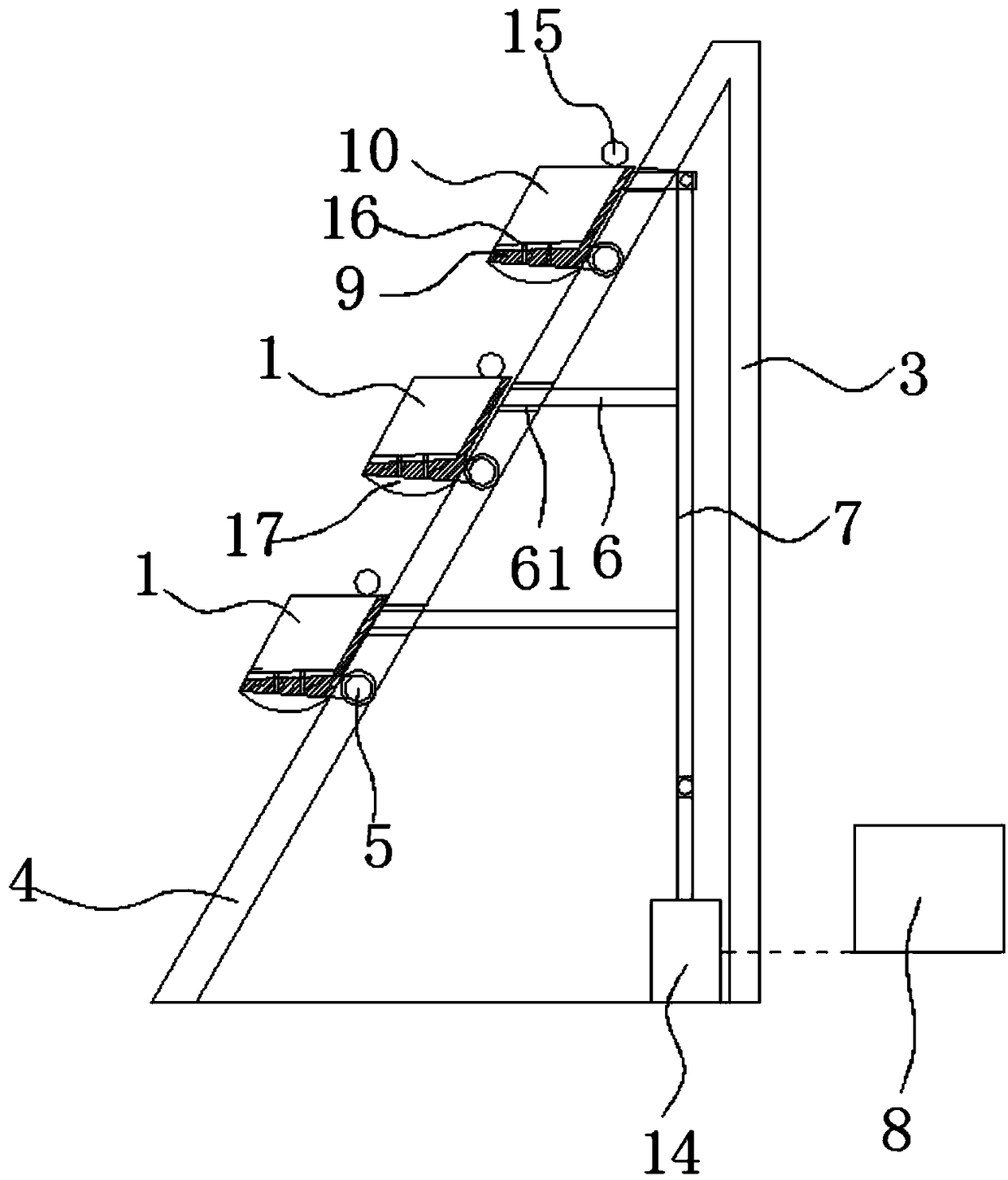

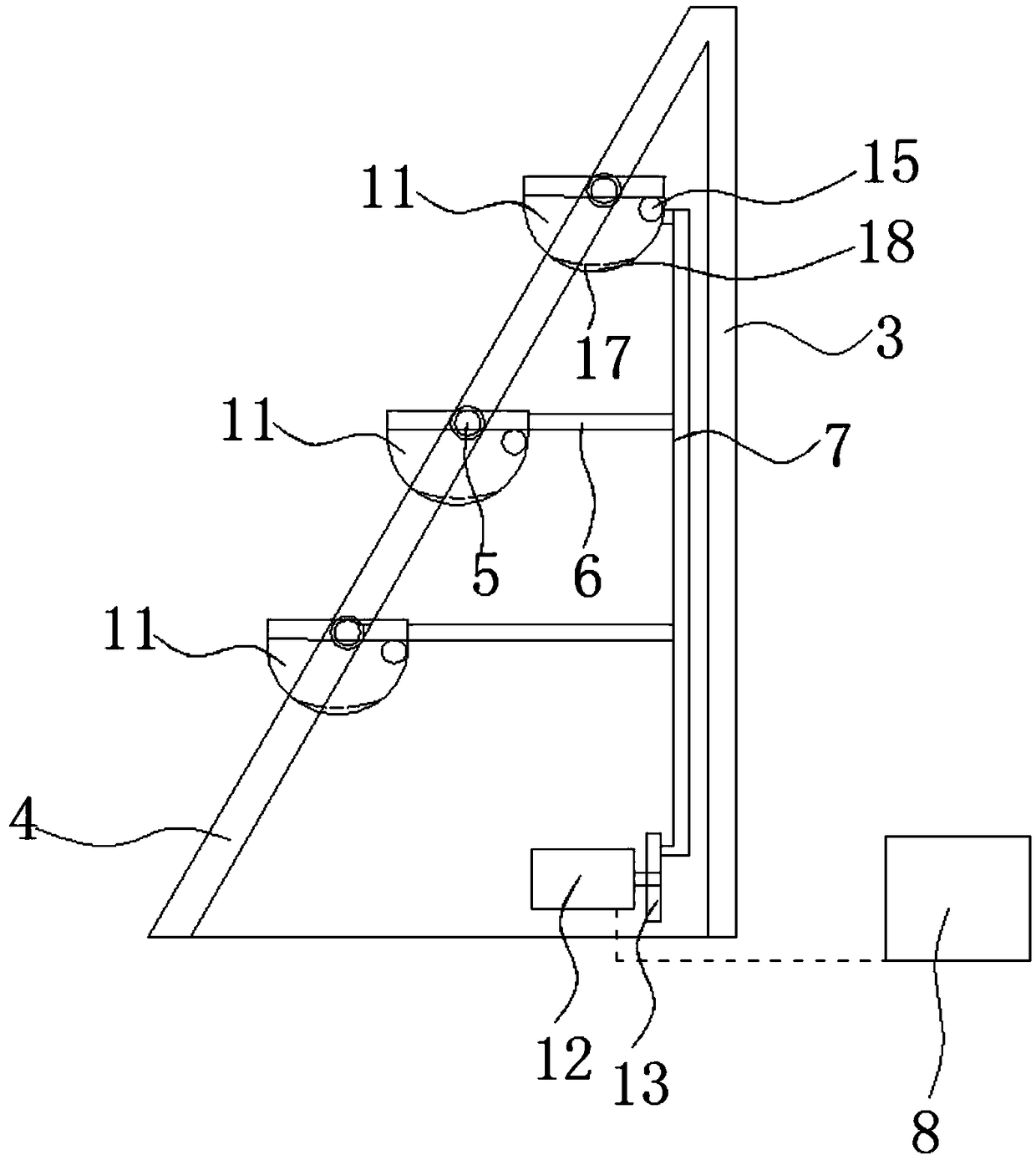

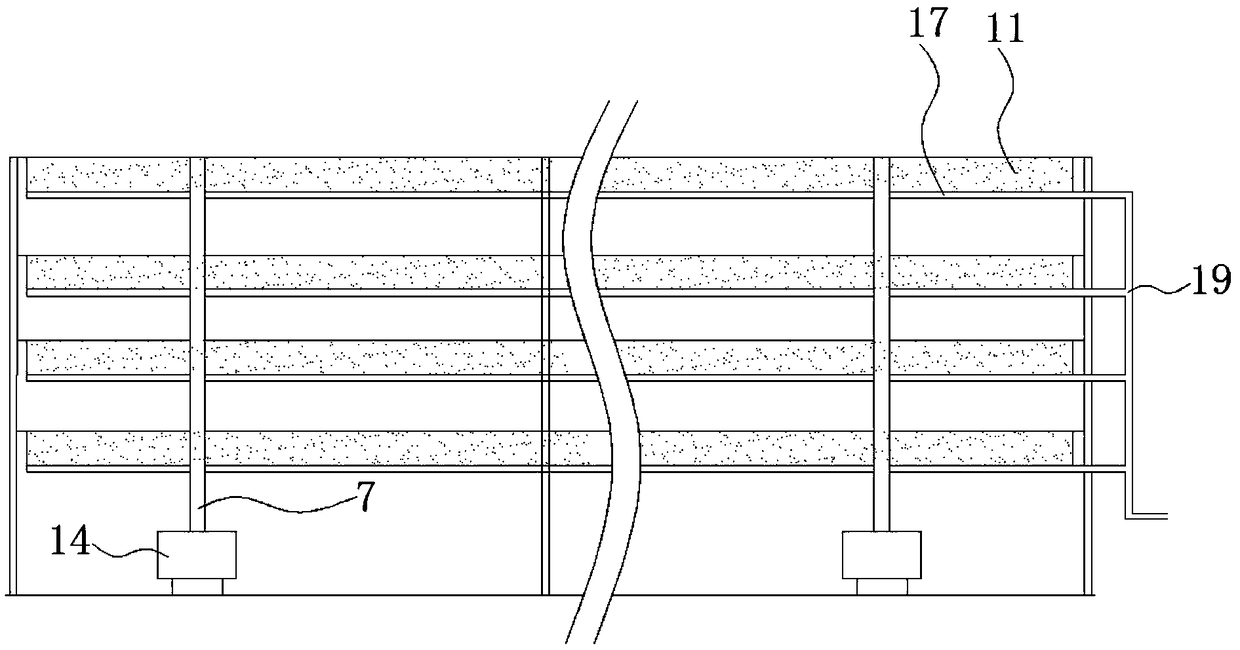

[0021] like Figures 1 to 3 Shown, a kind of strawberry elevated cultivation device comprises a cultivation frame, and the cultivation frame includes a vertical frame 3 arranged perpendicular to the ground and a placement frame 4 arranged obliquely, and a rotatable rotating shaft 5 is provided on the length direction of the placement frame 4. There is a cultivation groove on the rotating shaft 5, and the cultivation substrate is filled in the cultivation groove; the cultivation substrate is evenly prepared with peat, vermiculite, and perlite in a ratio of 2:1:1, and a horizontal connection is set on the back side of the cultivat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com