Structural parameter optimization method for non-contact R-test measuring instrument

A non-contact, structural parameter technology, applied in measurement devices, instruments, electrical devices, etc., can solve the problems of low measurement accuracy and poor measurement sensitivity, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

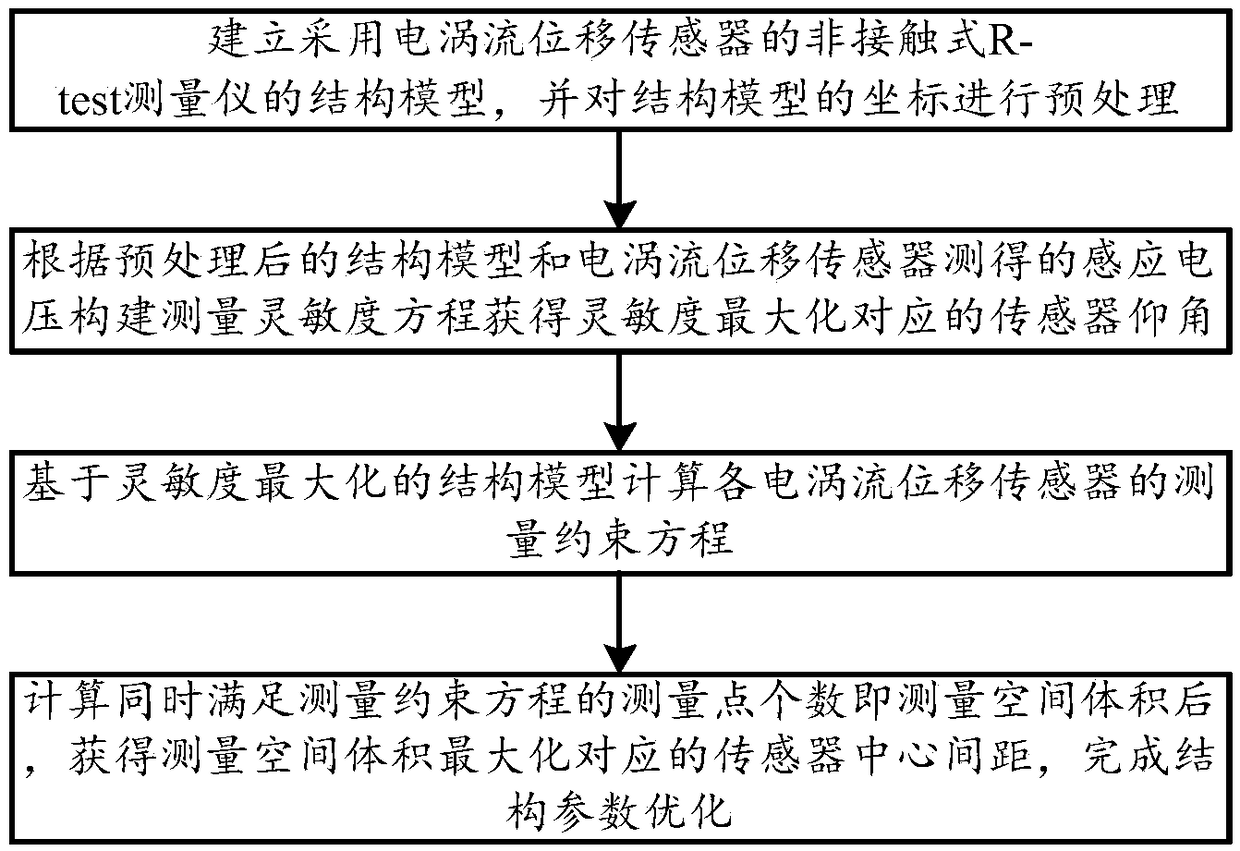

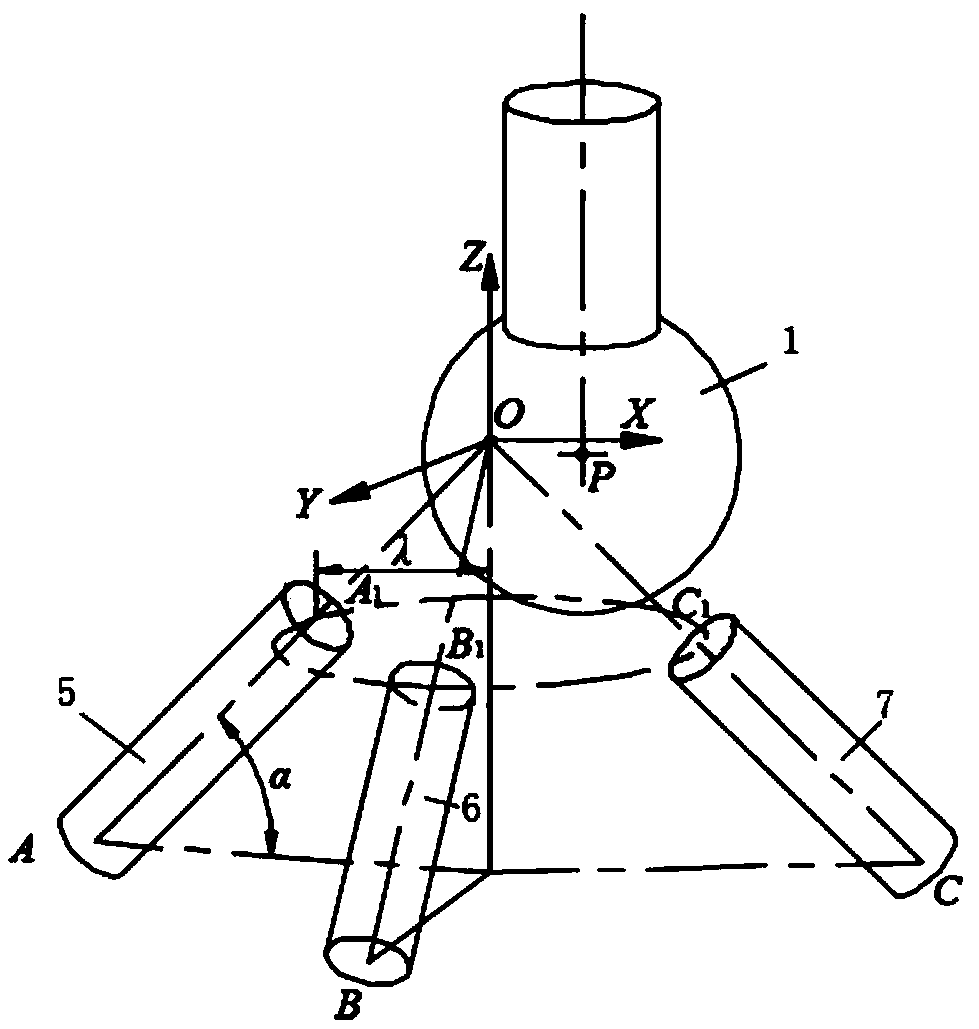

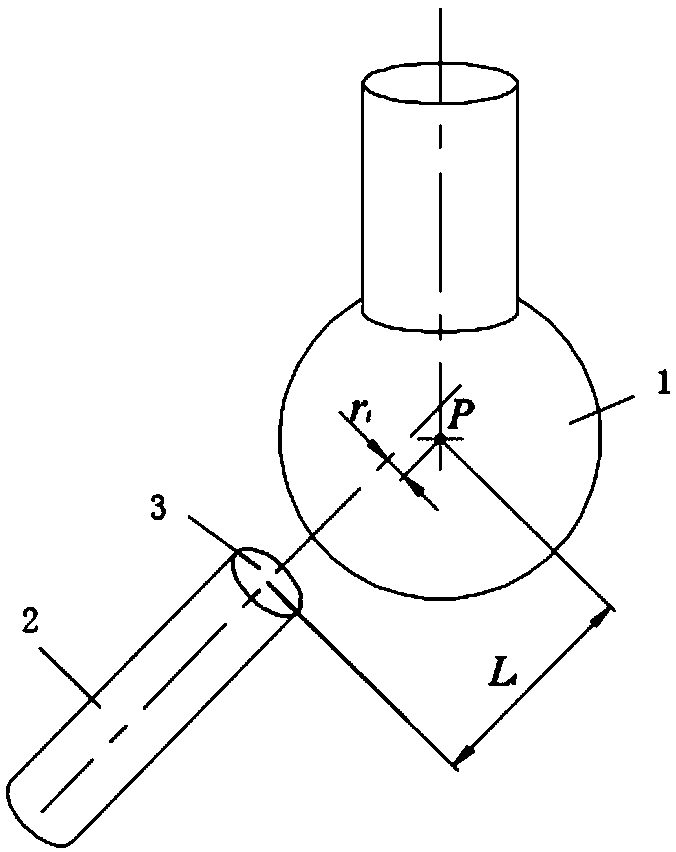

[0110] Such as figure 2 , 3 , 5 and 6, establish a structural model including three non-contact eddy current displacement sensors and a measuring ball 1 uniformly distributed; the three non-contact eddy current displacement sensors are respectively sensor A5, sensor B6 and sensor C7; Such as Figure 4 As shown, the measurement sensitivity index Prec of the non-contact R-test measuring instrument changes with the change of the sensor elevation angle α, first monotonically increasing and then monotonically decreasing. It is determined that when α=33.69°, the measurement sensitivity index Prec reaches the maximum; On the basis of measurement sensitivity (take α=33.69°), the relationship between the measurement space S of the non-contact R-test measuring instrument and the sensor center distance λ (r max = 4mm, R 探 = 7mm, R 球 =15mm, δ=4mm) As shown in 8, it is determined that when λ=14mm, the measurement space S is the largest, about 33mm 3 .

[0111] The calculation proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com