Construction method for eliminating construction joints between basement floor and wallboard

A technology of basement floor and construction method, which is applied to artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of poor visual effect and inconvenient construction methods of basement floor and wall panels, and achieves reasonable design, improved visual effect, The effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The construction method for eliminating basement floor and wall panel construction joints of the present invention comprises the following steps:

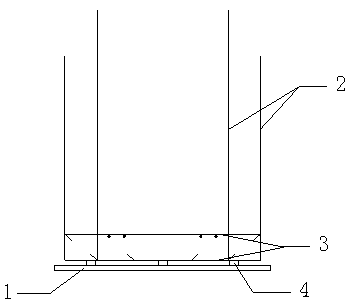

[0032] a. After the basement floor cushion is poured, measure and set out the line, and install the basement floor reinforcement; figure 1 It is a schematic diagram of the reinforcement structure of the basement floor according to the embodiment of the present invention.

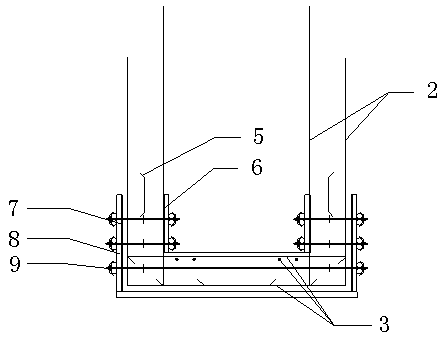

[0033] b. After the installation and acceptance of steel bars is qualified, the basement floor formwork shall be closed. The formwork is a 12mm thick plywood wood formwork, the tie rods are steel pipes with a diameter of 8mm, and the distance between the steel pipes is 400mm. figure 2 It is a schematic diagram of installation of the basement floor formwork of the embodiment of the present invention.

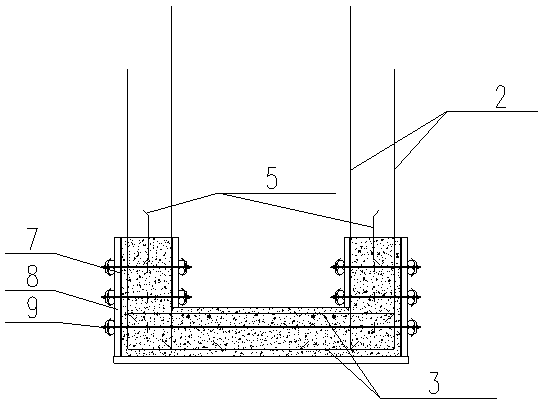

[0034] c. After the formwork is accepted, the basement floor concrete is poured; image 3 It is a schematic diagram of pouring concrete for the basement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com