Mould-proof oil-resistant chef uniform fabric

A chef and mildew-proof technology, applied in the field of clothing fabric processing, can solve the problems of chef clothes not being mold-proof and oil-resistant, chef clothes no longer clean and tidy, and increasing hotel operating costs, so as to avoid hot and sticky feeling, and avoid discoloration and mildew, the effect of inhibiting the growth of mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

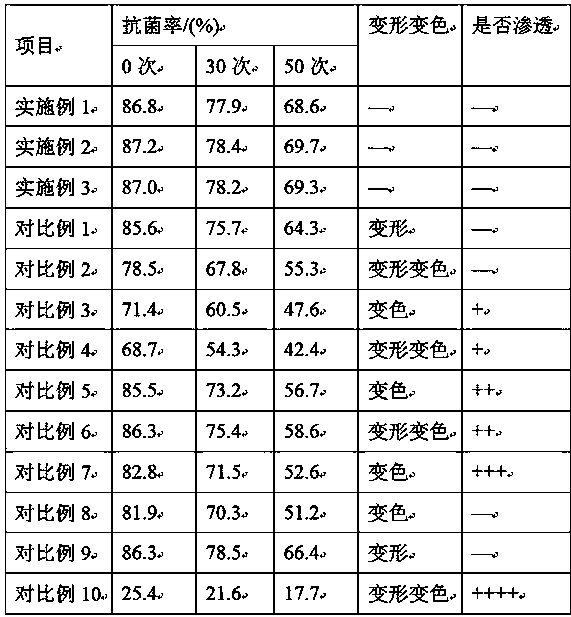

Examples

Embodiment 1

[0017] A mildew-resistant and oil-resistant chef's clothing fabric, made of the following raw materials in parts by weight: flax fiber 43, bamboo fiber 31, chitosan fiber 12, Ag-polyurethane fiber 3, polytetrafluoroethylene 2.5, acrylate emulsion 1.7, Modified nano vermiculite 1.4.

[0018] For the Ag-polyurethane fiber, heat the polyurethane particles to fully melt, heat and stir for 10 minutes, then add pentaerythritol of 2% by weight of the polyurethane, heat and stir at 110r / min for 8 minutes to improve the flexibility of the polyurethane, and then add nano-silver while stirring , the addition amount is 0.5% of the polyurethane weight, adjust the vacuum degree to -57kPa, keep stirring for 20min, improve the antibacterial properties and strength of polyurethane, melt spinning, the linear density is 1.45~1.47dtex, and obtain Ag-polyurethane fiber.

[0019] For the modified nano-vermiculite, crush the vermiculite to 100 mesh, add water 0.8 times the weight of the vermiculite,...

Embodiment 2

[0027] A mildew-resistant and oil-resistant chef's clothing fabric, made of the following raw materials in parts by weight: flax fiber 44, bamboo fiber 32, chitosan fiber 13, Ag-polyurethane fiber 4, polytetrafluoroethylene 2.6, acrylate emulsion 1.8, Modified nano vermiculite 1.5.

[0028] For the Ag-polyurethane fiber, heat the polyurethane particles to fully melt, heat and stir for 13 minutes, then add 2.5% pentaerythritol by weight of the polyurethane, heat and stir at 120r / min for 9 minutes to improve the flexibility of the polyurethane, and then add nano-silver while stirring , the addition amount is 0.6% of polyurethane weight, adjust the vacuum degree to -58kPa, heat preservation and stirring for 25min, improve the antibacterial property and strength of polyurethane, melt spinning, the linear density is 1.46dtex, get Ag-polyurethane fiber.

[0029] For the modified nano-vermiculite, crush the vermiculite to 120 mesh, add water of 1.0 times the weight of the vermiculite...

Embodiment 3

[0037] A mildew-resistant and oil-resistant chef's clothing fabric is made of the following raw materials in parts by weight: flax fiber 45, bamboo fiber 33, chitosan fiber 14, Ag-polyurethane fiber 5, polytetrafluoroethylene 2.7, acrylate emulsion 1.9, Modified nano vermiculite 1.6.

[0038] For the Ag-polyurethane fiber, heat the polyurethane particles to fully melt, heat and stir for 15 minutes, then add 3% pentaerythritol by weight of the polyurethane, heat and stir at 130r / min for 10 minutes to improve the flexibility of the polyurethane, and then add nano-silver while stirring , the addition amount is 0.7% of polyurethane weight, adjust the vacuum degree to -59kPa, heat preservation and stirring for 30min, improve the antibacterial property and strength of polyurethane, melt spinning, the linear density is 1.47dtex, get Ag-polyurethane fiber.

[0039] For the modified nano-vermiculite, crush the vermiculite to 140 mesh, add water 1.2 times the weight of the vermiculite, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com