Ssilk protein aerogel for friction nano electric generator as well as preparation method thereof and friction nano electric generator

A nanogenerator, silk protein technology, applied in triboelectric generators, organic material conductors, non-metallic conductors and other directions, can solve the problem of lack of electropositive materials, and achieve easy regulation of specific surface area, stable output performance, and simple preparation method. Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

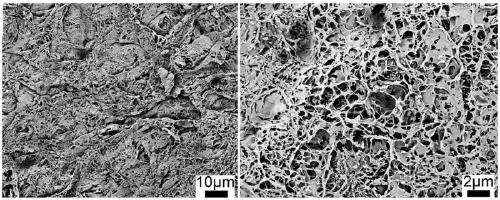

[0043] This embodiment provides a preparation method of silk airgel for triboelectric nanogenerator, which specifically includes the following steps:

[0044] S1. Prepare a silk protein solution with a concentration of 2%, store the prepared solution at 4°C, pour 15mL of the silk protein solution into an aluminum plate with a diameter of 55mm, and freeze it in a mixed bath of acetone and dry ice for 10 minutes , and then pre-freeze at -40°C for 1 hour until freezing;

[0045] S2. Freeze-dry the pre-frozen solution at -80° C. for 3 days to obtain the silk protein airgel, and compress the obtained silk protein airgel into a thin film of 0.2 mm.

[0046] This embodiment also provides a method for preparing polyvinylidene fluoride airgel, which specifically includes the following preparation steps:

[0047] Y1. Dissolve 1g of polyvinylidene fluoride in 20mL of dimethylformamide to make a 5% solution, apply the prepared solution evenly on the glass surface, and soak it in a water ...

Embodiment 2

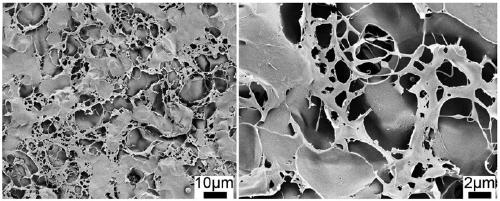

[0051] This example refers to the preparation method of Example 1, the difference is that: the concentration of the silk protein solution configured in step S1 is 1%; the freeze-drying temperature in step S2 is -50°C; the concentration of polyvinylidene fluoride in step Y1 10%.

Embodiment 3

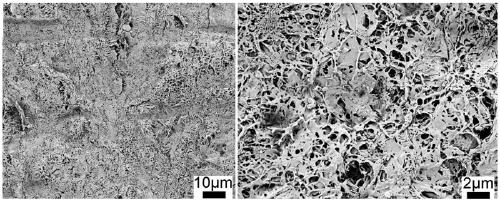

[0053]This example refers to the preparation method of Example 1, except that the concentration of the silk protein solution configured in step S1 is 4%; the freeze-drying temperature in step S2 is -65°C; the concentration of polyvinylidene fluoride in step Y1 is 7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com