Composite thin film with mn doping to regulate resistance switching effect and preparation method thereof

A composite film and resistance switch technology, applied in the coating and other directions, can solve the problems that affect the characteristics of composite film resistance switching, restrict the practical application of materials, etc., and achieve the effects of suppressing valence fluctuations, improving ferromagnetism, and reducing leakage current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

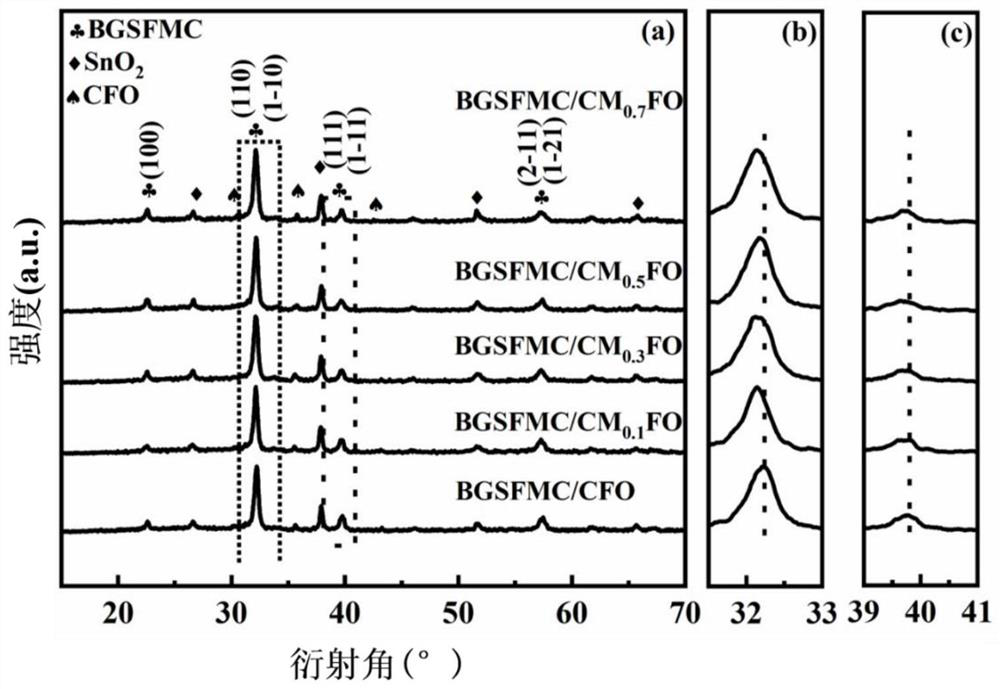

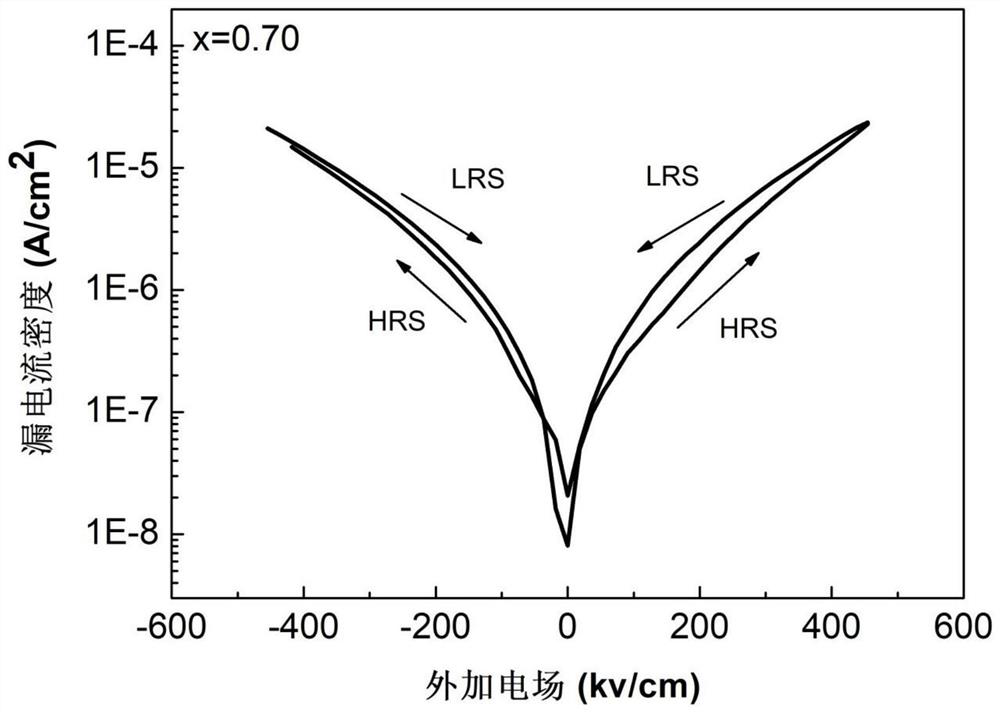

[0033] The BGSFMC / C with resistive switching effect 1-x m x The preparation method of FO composite film, comprises the following steps:

[0034] Step 1: Dissolve cobalt nitrate, manganese acetate and ferric nitrate in ethylene glycol methyl ether in a molar ratio of (1-x):x:2, stir evenly, add acetic anhydride, continue stirring evenly, and obtain the bottom film precursor ;wherein x=0.1~0.7;

[0035] Step 2: Spin-coat the bottom layer film precursor solution on the FTO / glass substrate to obtain a wet film. After the wet film is evenly glued, it is baked at 190-195°C to obtain a dry film, and then annealed in air at 660-710°C , to obtain crystalline Co 1-x mn x Fe 2 o 4 film;

[0036] Step 3: The crystalline Co 1-x mn x Fe 2 o 4 The film was cooled to room temperature, and step 2 was repeated until the preset thickness was reached, that is, the underlying Co 1-x mn x Fe 2 o 4 film.

[0037] Step 4: Dissolve bismuth nitrate, gadolinium nitrate, strontium nitrate...

Embodiment 1

[0050] Step 1: Clean the FTO / glass substrate with detergent, acetone, and absolute ethanol respectively and seal it in absolute ethanol for later use;

[0051] Step 2: Cobalt nitrate, manganese acetate and ferric nitrate are used as raw materials, dissolved in ethylene glycol methyl ether at a molar ratio of 0.9:0.1:2 (x=0.1), stirred for 30 minutes, then added with acetic anhydride, stirred for 90 minutes to obtain metal Stable bottom film precursor solution with a total ion concentration of 0.2mol / L; wherein the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1;

[0052] Step 3: Wash the FTO / glass substrate with deionized water and use N 2 Blow dry, and then irradiate the clean FTO / glass substrate with a UV irradiator for 40 minutes to make the surface of the FTO / glass substrate reach atomic cleanliness, and then spin-coat the bottom layer film precursor solution on the FTO / glass substrate, and the uniform coating speed The temperature is 4000r / min, a...

Embodiment 2

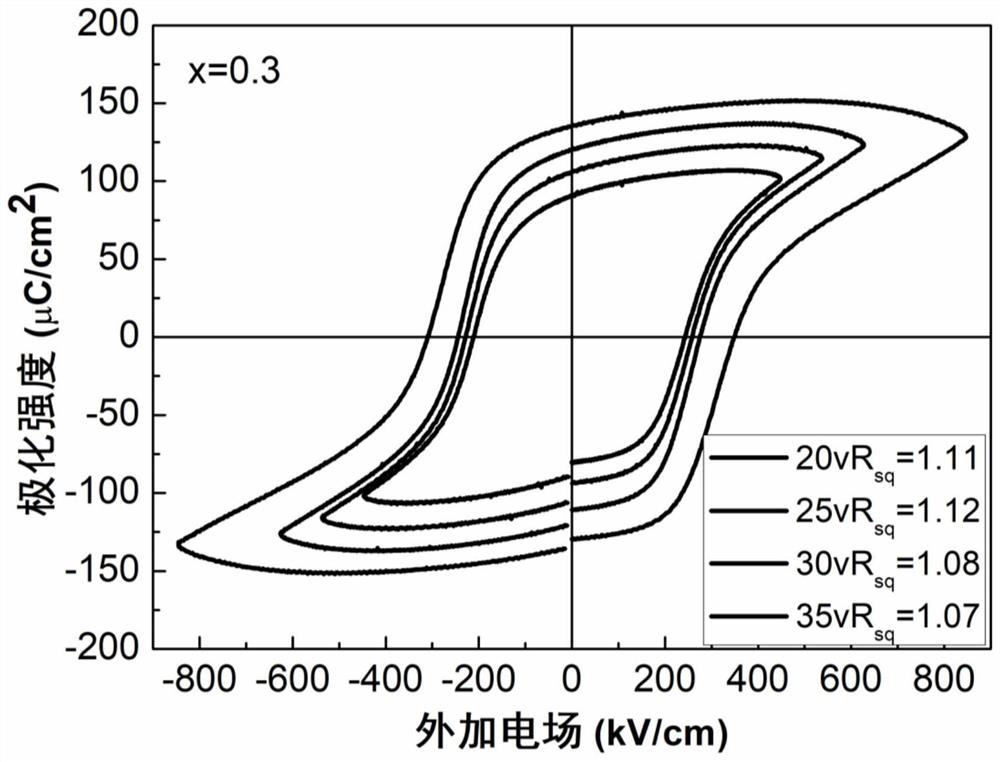

[0057] Step 1: Clean the FTO / glass substrate with detergent, acetone, and absolute ethanol respectively and seal it in absolute ethanol for later use;

[0058] Step 2: Cobalt nitrate, manganese acetate and ferric nitrate are used as raw materials, dissolved in ethylene glycol methyl ether at a molar ratio of 0.7:0.3:2 (x=0.3), stirred for 30 minutes, then added with acetic anhydride, stirred for 90 minutes to obtain metal Stable bottom film precursor solution with a total ion concentration of 0.2mol / L; wherein the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1;

[0059] Step 3: Wash the FTO / glass substrate with deionized water and use N 2 Blow dry, and then irradiate the clean FTO / glass substrate with an ultraviolet light irradiation instrument for 40 minutes, so that the surface of the FTO / glass substrate reaches atomic cleanliness, and then spin-coat the precursor solution on the FTO / glass substrate, and the coating speed is 4000r / min, the homogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com