SSZ-13 molecular sieve synthesis method

A synthesis method and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem that the template agent is expensive, increase the synthesis cost of SSZ-13 molecular sieve, and limit the popularization and use of SSZ-13 molecular sieve, etc. problem, to achieve the effect of easy preparation and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First, mix 1.658g of sodium metaaluminate (aluminum source) with 24.14g of pure water. After the dissolution is complete, add 1.100g of sodium hydroxide and stir for 10 minutes to completely dissolve. Then add 2.793g of choline chloride, stir for 15 minutes and then add 16.88g of 25wt% N,N,N-trimethyl-1-adamantanamine cation aqueous solution, vigorously stir to make it completely mixed, and dropwise Add 40.0 g of LUDOX-AS-30 silica sol (silicon source).

[0030] Stir at room temperature for 20 hours, and finally transfer the colloid to a stainless steel autoclave lined with polytetrafluoroethylene, put it in an oven at 140°C and keep it for 14 days.

[0031] The product was collected by filtration, washed until the filtrate was neutral, dried in an oven at 100°C for 12 hours, and then calcined in a tube furnace at 550°C for 8 hours to remove the template agent to obtain SSZ-13 molecular sieve.

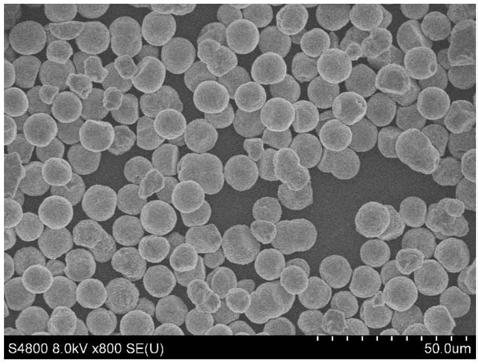

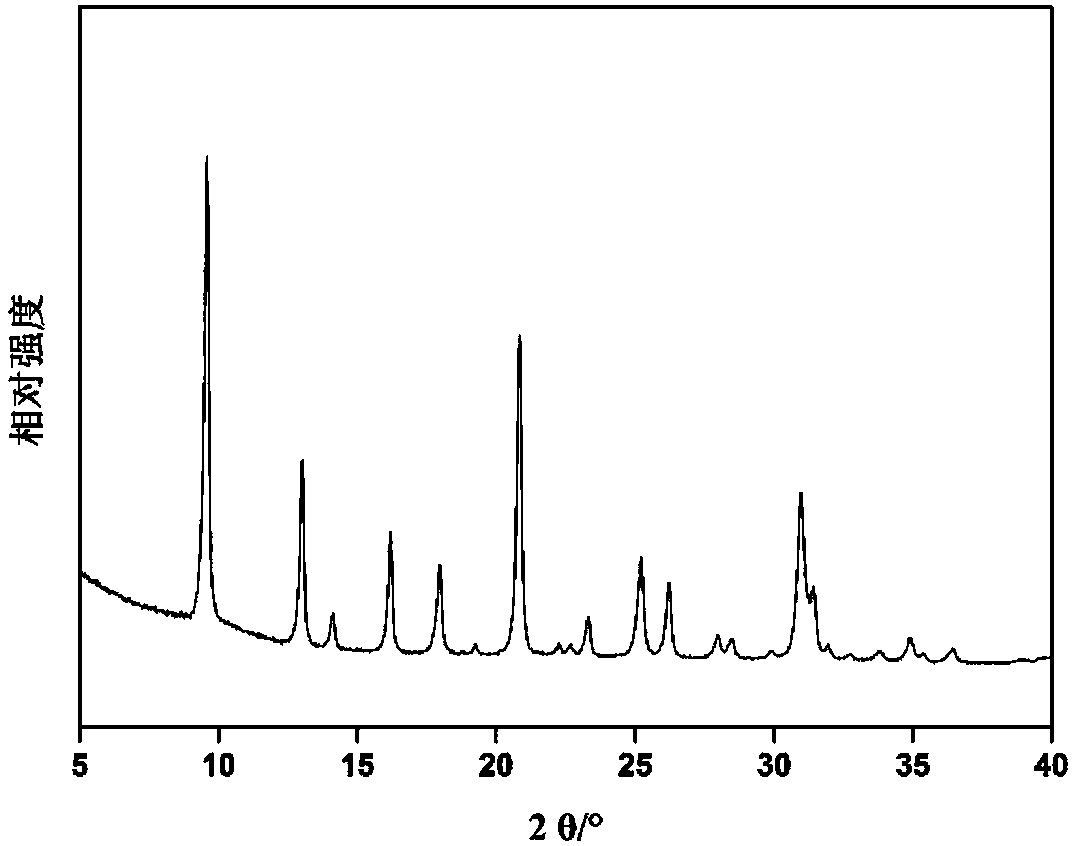

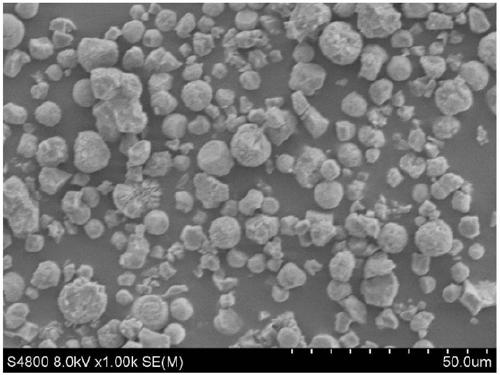

[0032] The SEM picture and XRD spectrum of the prepared SSZ-13 molecular s...

Embodiment 2

[0034] First, mix 1.056g of sodium hydroxide with 25.27g of pure water. After the dissolution is complete, add 2.752g of aluminum isopropoxide (aluminum source), and stir rapidly to make it completely hydrolyzed. Then add 2.793g choline chloride, stir for 15 minutes and add 17.93g 25wt% N,N,N-trimethyl-1-adamantanamine cation aqueous solution, vigorously stir to make it mix completely, and gradually 41.18 g of LUDOX-AS-30 silica sol (silicon source) were added dropwise.

[0035] Stir at room temperature for 20 hours, and finally transfer the colloid to a stainless steel autoclave lined with polytetrafluoroethylene, put it in an oven at 140°C and keep it for 15 days.

[0036] The product was collected by filtration, washed until the filtrate was neutral, dried in an oven at 100°C for 12 hours, and then calcined in a tube furnace at 550°C for 8 hours to remove the template agent to obtain SSZ-13 molecular sieve.

[0037] The SEM picture and XRD spectrum of the prepared SSZ-13 m...

Embodiment 3

[0039] First, mix 1.723g of sodium metaaluminate (aluminum source) with 20g of pure water. After the dissolution is complete, add 1.300g of sodium hydroxide and stir for 10 minutes to completely dissolve. Then add 2.936g of choline chloride, stir for 15 minutes and then add 17.15g of 25wt% N,N,N-trimethyl-1-adamantanamine cation aqueous solution, vigorously stir to make it completely mixed, and dropwise 38.56 g of LUDOX-AS-30 colloidal silica (silicon source) were added.

[0040] Stir at room temperature for 20 hours, and finally transfer the colloid to a stainless steel autoclave lined with polytetrafluoroethylene, put it in an oven at 140°C and keep it for 12 days.

[0041] The product was collected by filtration, washed until the filtrate was neutral, dried in an oven at 100°C for 12 hours, and then calcined in a tube furnace at 550°C for 8 hours to remove the template agent to obtain SSZ-13 molecular sieve.

[0042] The SEM picture and XRD spectrum of the prepared SSZ-13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com