A desktop four-axis linkage fiber winding machine for grid structure forming

A fiber winding machine and four-axis linkage technology, which is applied in the field of composite material forming, can solve the problem that the winding machine cannot meet the requirements of mesh structure winding micro-spacecraft components, etc., to reduce fiber accumulation and overhead defects, easy maintenance and use, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

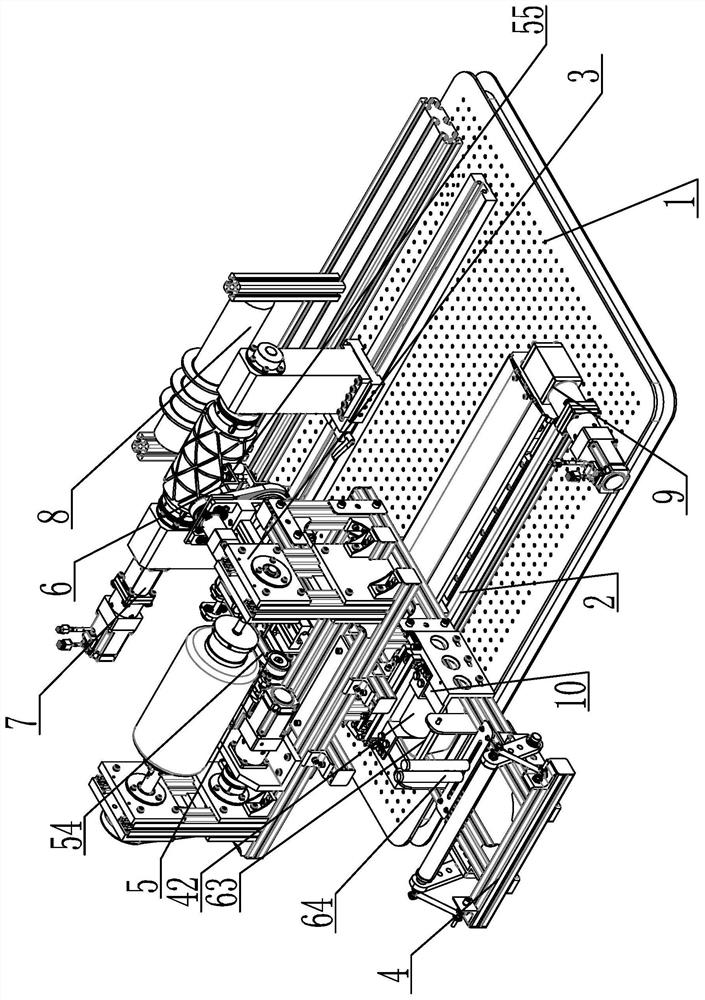

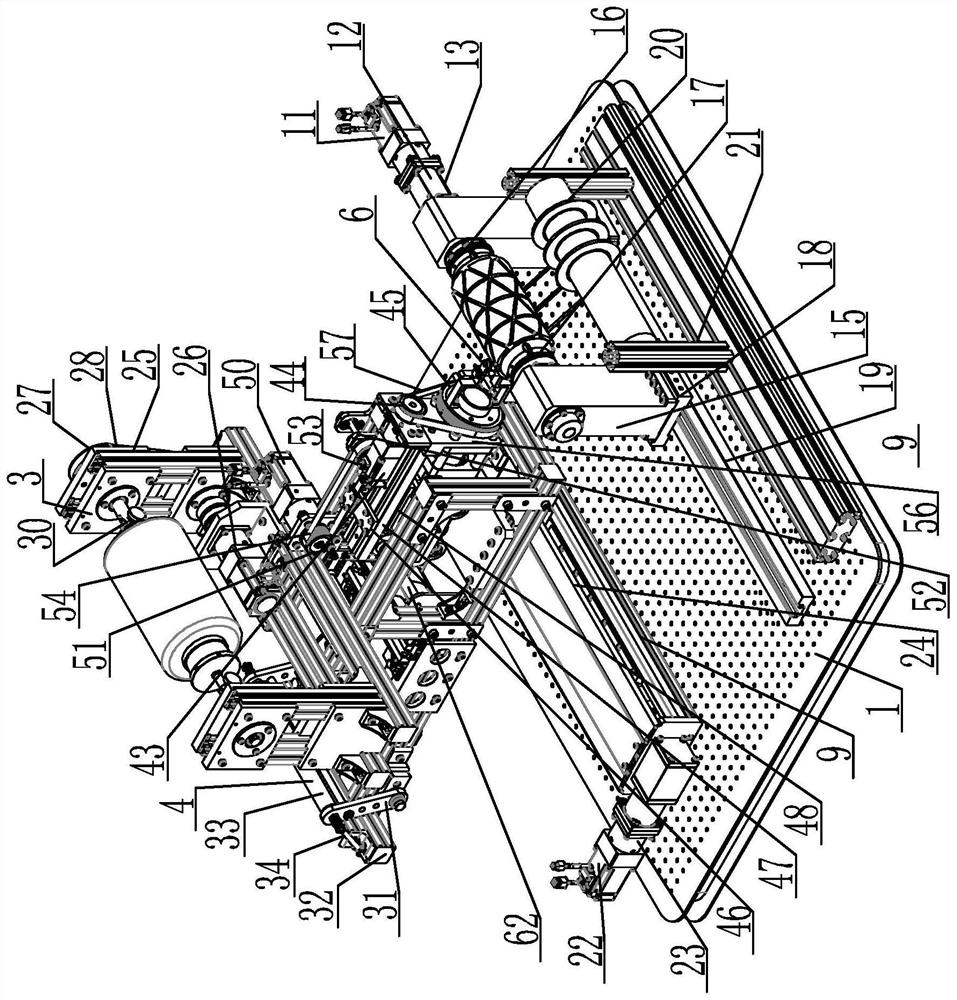

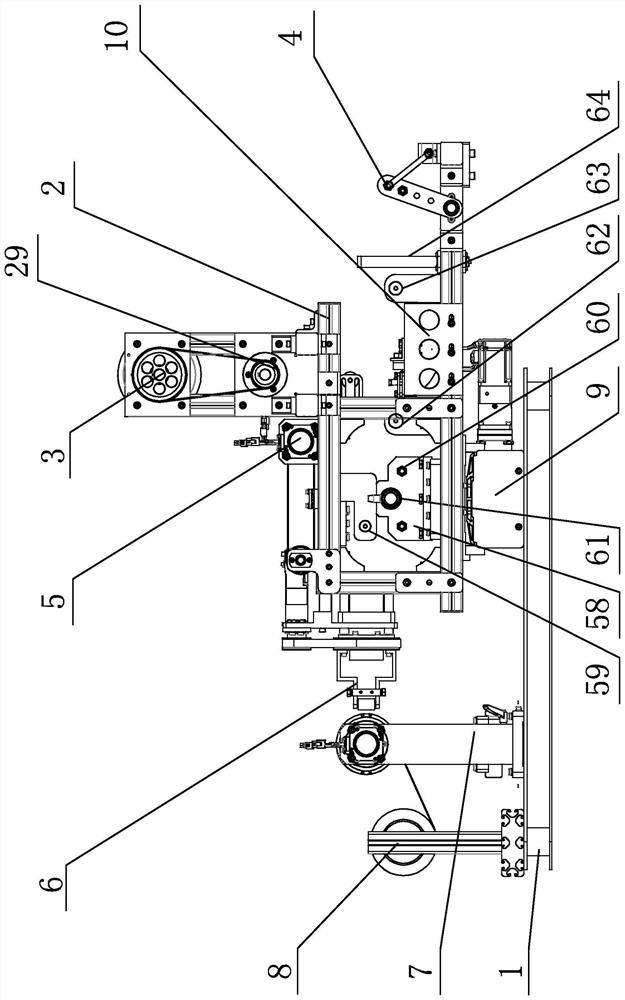

[0016] Specific implementation mode one: combine Figure 1-Figure 8 Describe this embodiment, a desktop four-axis linkage fiber winding machine for grid structure forming described in this embodiment, which includes a machine tool platform 1, a moving frame body 2, a frame body moving drive mechanism 9, and a fiber unwinding mechanism 3. Yarn picking mechanism 4, rubber dipping mechanism 10, telescopic arm assembly 5, thread nozzle assembly 6, main shaft rotating part 7 and circumferential rib winding assembly 8; frame moving drive mechanism 9, main shaft rotating part 7 and circumferential rib winding The component 8 is installed on the machine tool platform 1, the main shaft rotating part 7 is located between the frame body moving drive mechanism 9 and the circumferential rib winding assembly 8, the moving frame body 2 is installed on the frame body moving drive mechanism 9, the fiber unwinding mechanism 3, The yarn picking mechanism 4 , the dipping mechanism 10 , the telesc...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination Figure 1-Figure 5 Describe this embodiment, a desktop four-axis linkage fiber winding machine for grid structure forming described in this embodiment, the main shaft rotating part 7 includes a main shaft servo motor 11, a reducer 12, a main shaft servo motor coupling 13, Main shaft 14, mandrel, main shaft chuck 16, support chuck 17, slider 18, slide rail 19 and two main shaft supporting columns 15, main shaft servo motor 11, reducer 12, main shaft servo motor coupling 13, main shaft 14 , mandrel, main shaft chuck 16, and support chuck 17 are fixedly connected along a straight line in turn, and the outer casing of the main shaft servo motor 11 is fixedly connected with the housing of the reducer 12 and the bracket end of the main shaft servo motor coupling 13, and the main shaft servo motor The other end of the shaft coupling 13 is fixedly connected with a main shaft support column 15, the main shaft 14 is rotatably connecte...

specific Embodiment approach 3

[0019] Specific implementation mode three: combination Figure 1-Figure 5 Describe this embodiment, a desktop four-axis linkage fiber winding machine for grid structure forming described in this embodiment, the circumferential rib winding assembly 8 includes a creel 21 and a yarn cluster 20, and the yarn cluster 20 is installed on the creel 21, creel 21 is fixedly installed on machine tool platform 1. Other methods are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com