Polydopamine coated copper nanowire composite material as well as preparation method thereof and application thereof

A technology of polydopamine and composite materials, applied in the direction of nanotechnology, transportation and packaging, metal processing equipment, etc., can solve the problem of insufficient selectivity of stable methane, achieve improved chemical stability and thermal stability, simple preparation method, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

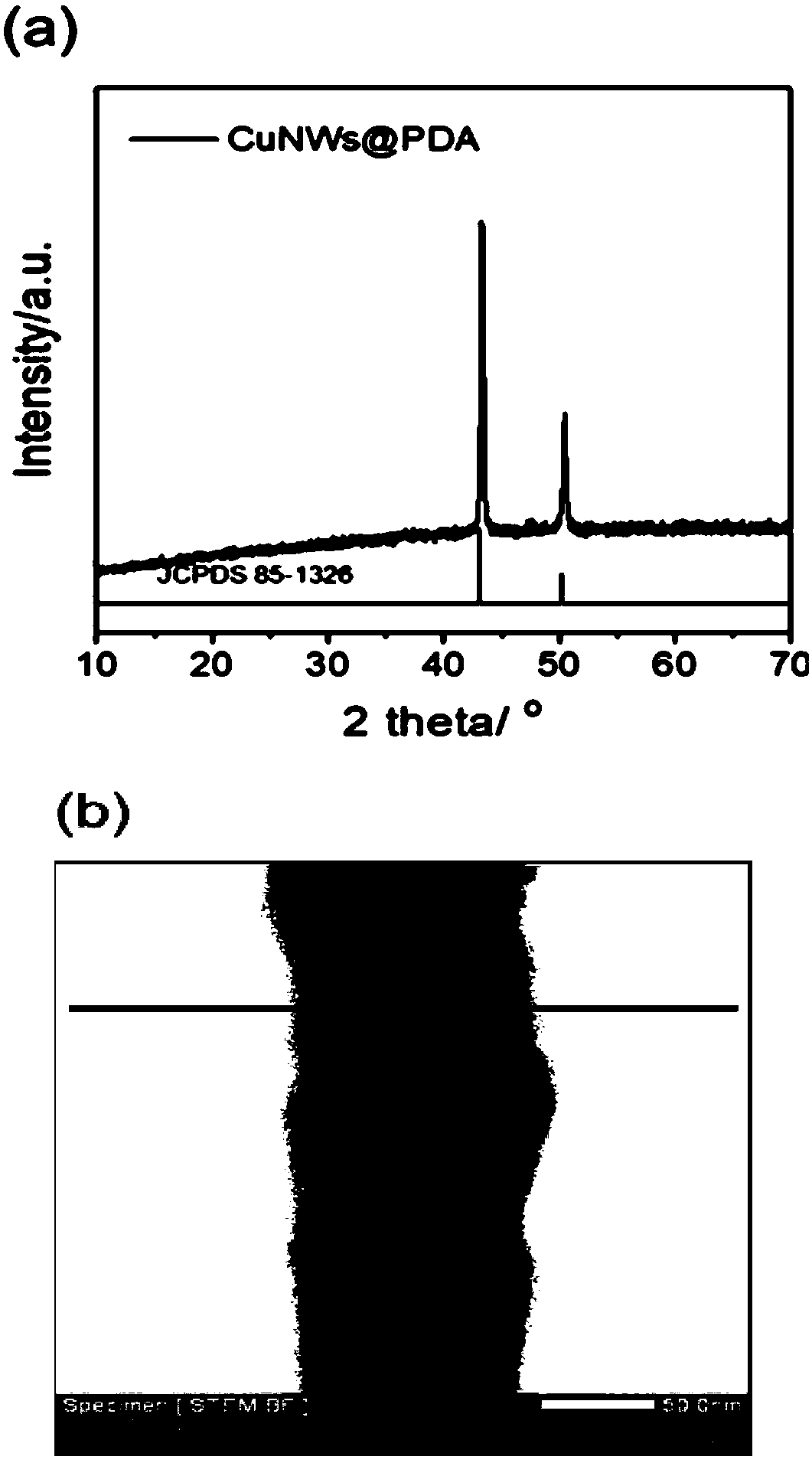

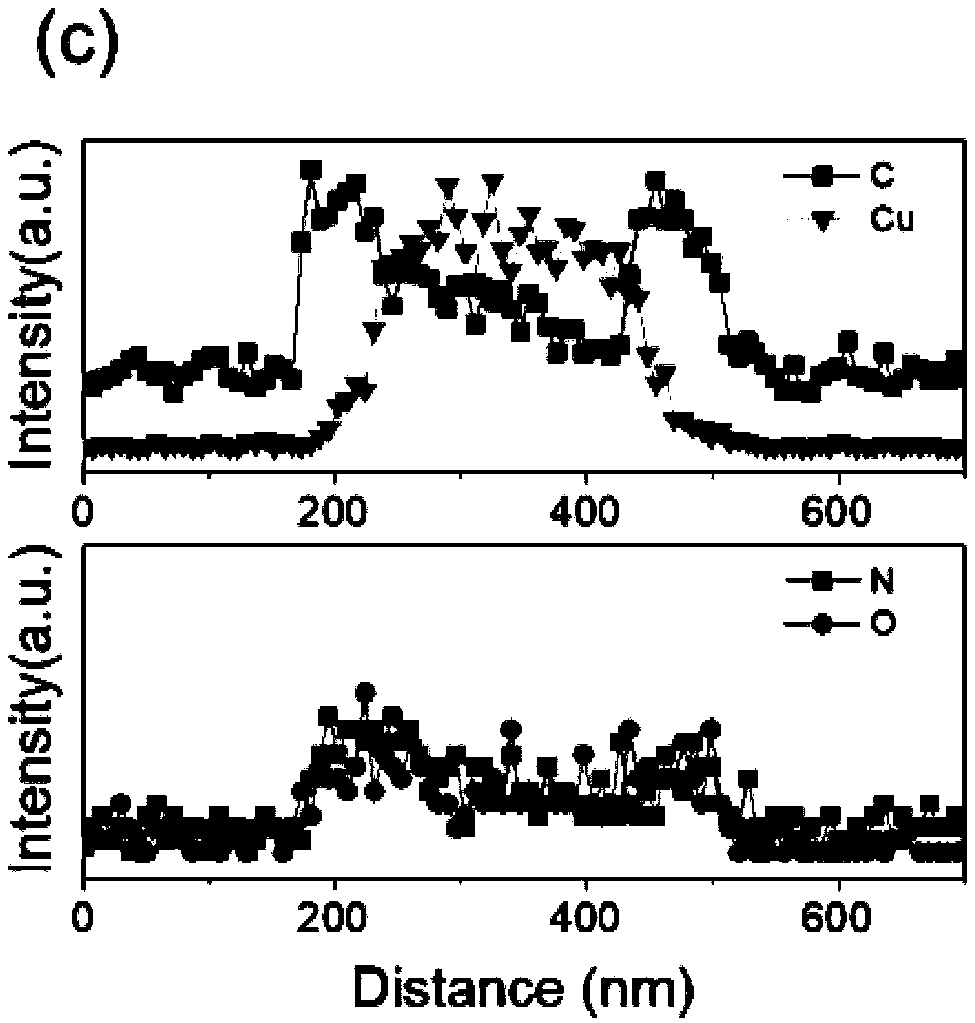

[0031] 1) Synthesis of polydopamine-wrapped modified copper nanowires:

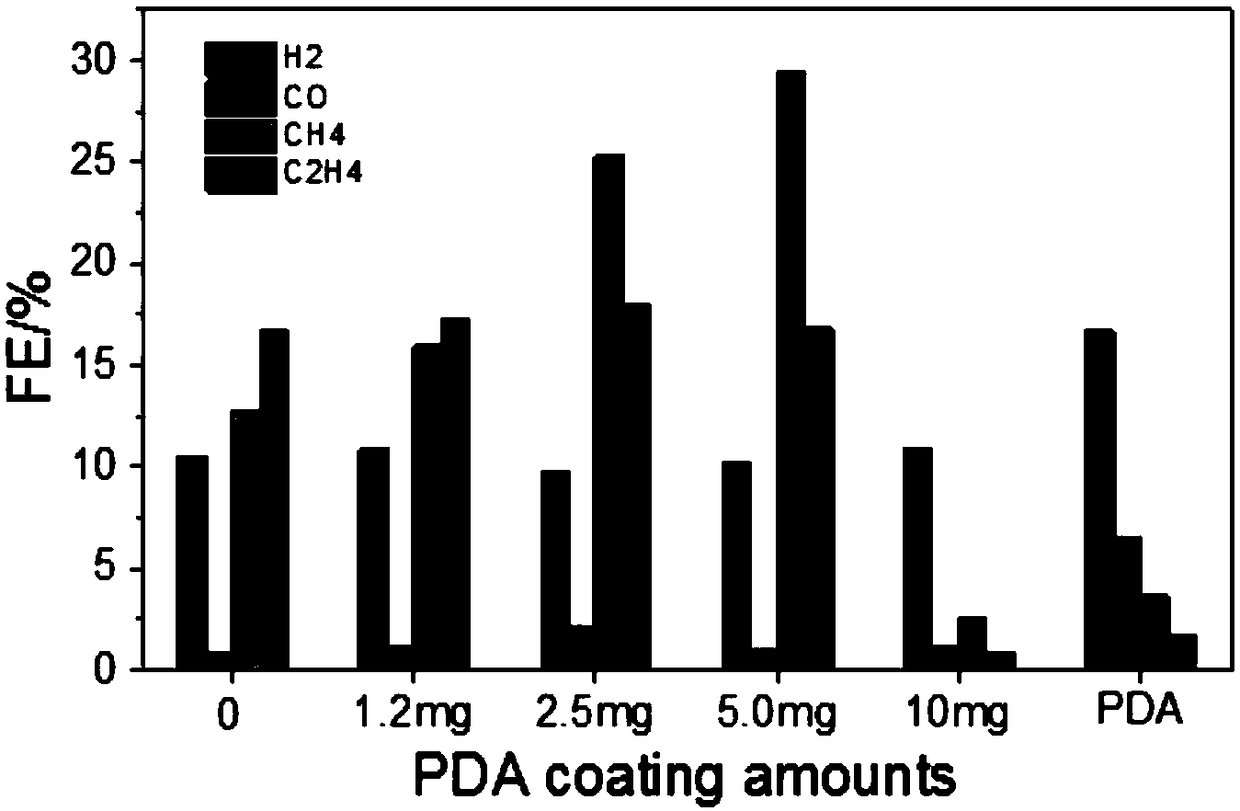

[0032] Take 20mL 15M NaOH (98%), 1mL 0.1M Cu(NO 3 ) 2 (98%), 0.1 mL of ethylenediamine (EDA, 99%) was placed in a three-necked flask, the flask was placed in a water bath at 70°C, and stirred at 250 rpm for 5 min. Then hydrazine hydrate (10.5 μl, N 2 H 4 ,35wt.%in H 2 O), increase the stirring rate to 2 times. The final Cu(NO 3 ) 2 ,EDA,N 2 H 4 The dosages are 4.74mM, 70mM, 5.5mM respectively. After 60min of reaction, suction filtration, and the brown-red solid on the filter membrane is washed with a large amount of 3% N 2 H 4 The solution was washed, and the obtained solid was placed in a vacuum drying oven at 60 °C for 8 h. Dissolve an appropriate amount of dopamine hydrochloride (1.2 mg, 2.5 mg, 5.0 mg, 10 mg) in 100 mL of deionized water, use KHCO 3 / K 2 CO 3 Solution Adjust the pH of the solution to 8.5. Weigh 50 mg of copper nanowires and ultrasonically disperse them in the above soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com