Environment-friendly type industrial waste gas pre-treatment device

A technology for pretreatment device and industrial waste gas, which is applied in combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of unsatisfactory purification effect of waste gas treatment device, etc. Simple and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

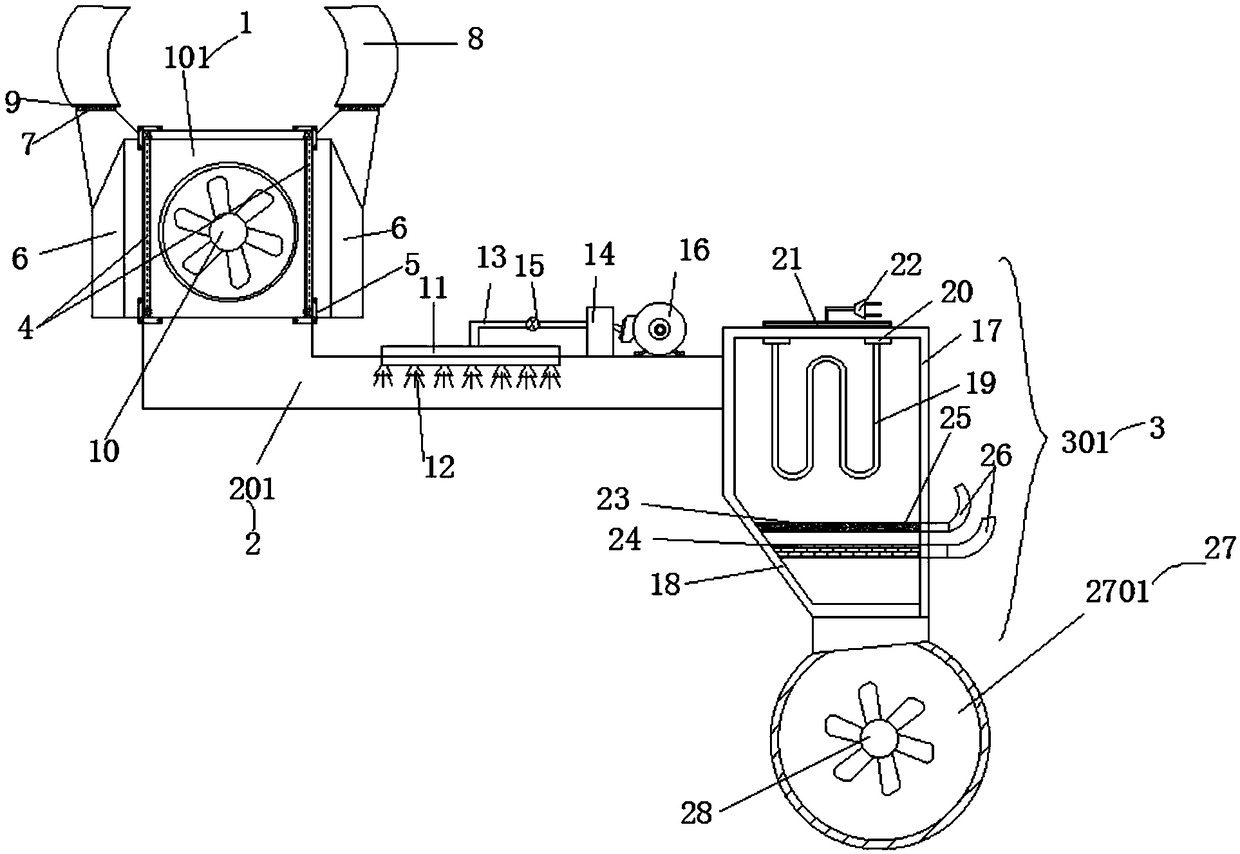

[0016] Embodiment 1: see figure 1 Now, an environment-friendly industrial waste gas pretreatment device provided by the present invention is described, including an air inlet assembly 1, a dust removal assembly 2 and a pretreatment assembly 3, the air inlet assembly 1 includes an air inlet box 101, and the air inlet The left and right sides of box body 101 are equipped with filter screen group 4, and the both sides of described filter screen group 4 are connected with air inlet passage 6 by flange 5, and the upper end of described air inlet passage 6 is provided with air inlet 7, and described air inlet The tuyere 7 is connected to the air delivery pipe 8, and the junction of the air inlet channel 6 and the air delivery pipe 8 is provided with a filter screen 9 for removing impurities, and the inside of the air inlet box 101 is equipped with an induced draft fan 10, and the air inlet box The lower end of the body 101 is connected to the dust removal assembly 2, the dust remova...

Embodiment 2

[0017] Example 2: see figure 1 , as an improvement of the present invention, the filter group 4 uses an aluminum alloy filter.

Embodiment 3

[0018] Embodiment 3: see figure 1 , as an improvement of the present invention, the mesh size of the filter group 4 is 5-6 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com