An epitaxial structure of a deep ultraviolet LED chip and a preparation method thereof

A technology of LED chip and epitaxial structure, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of quantum well active area loss, disadvantage, and improve the light output of deep ultraviolet LED, so as to improve the light extraction efficiency and light output power. , The effect of improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Epitaxial structure of a deep ultraviolet LED chip

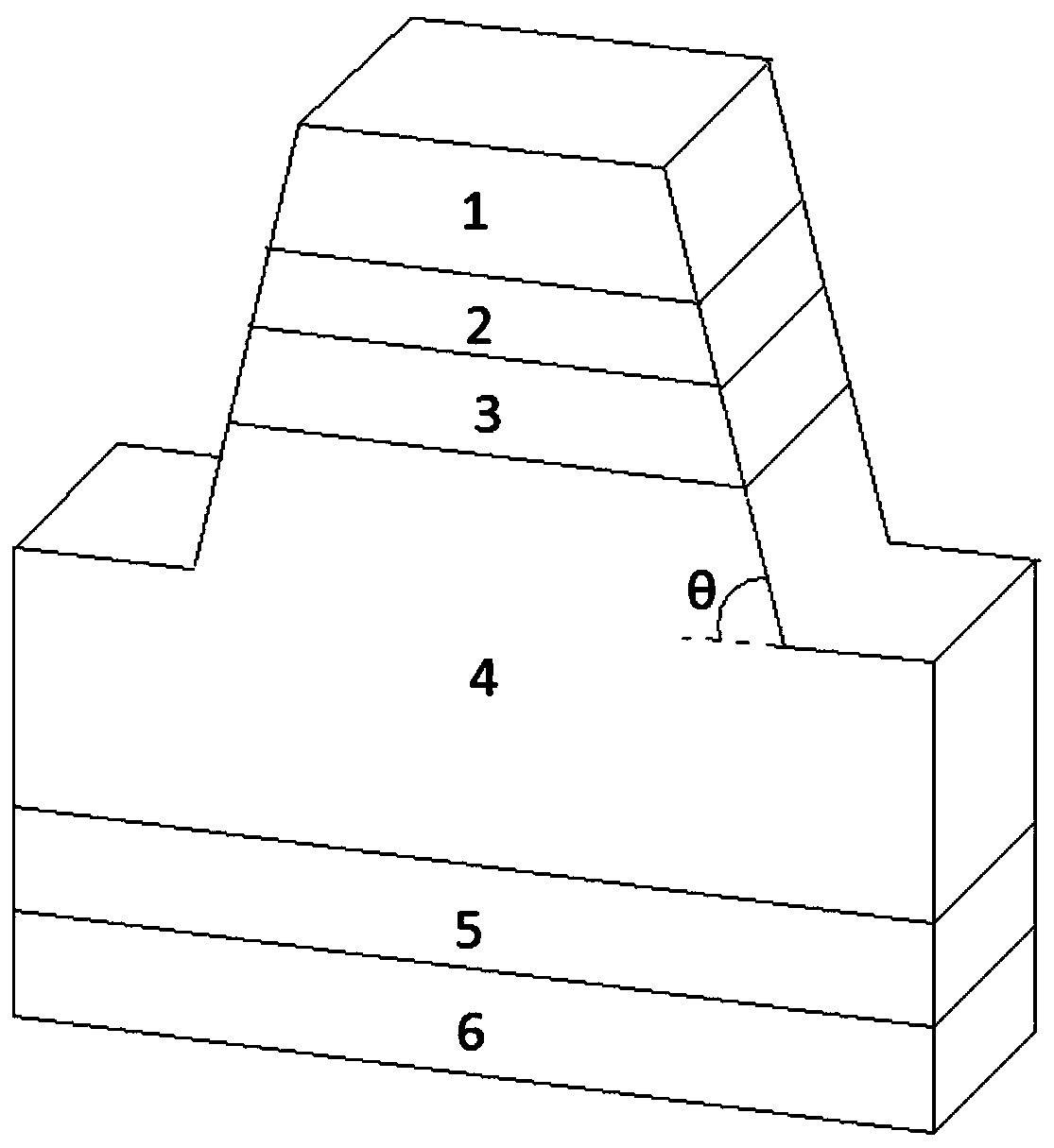

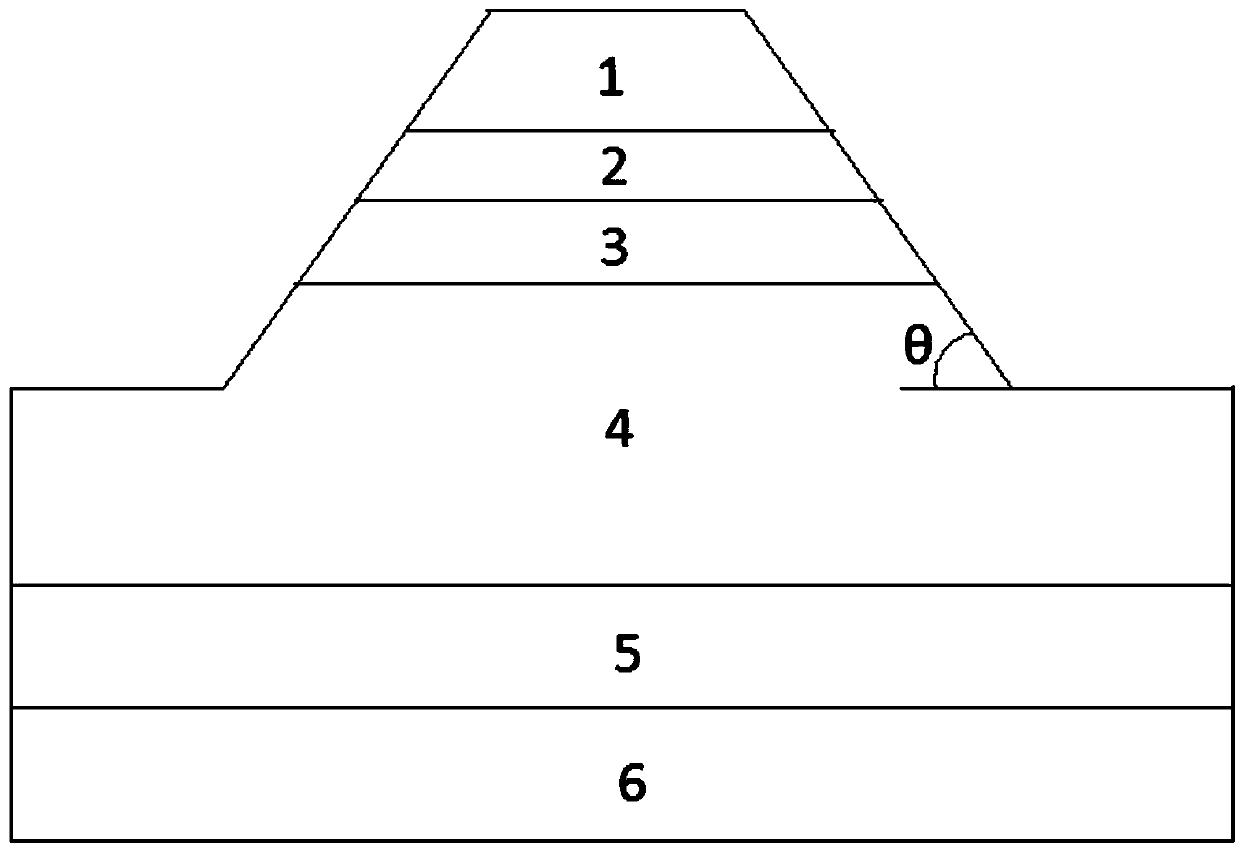

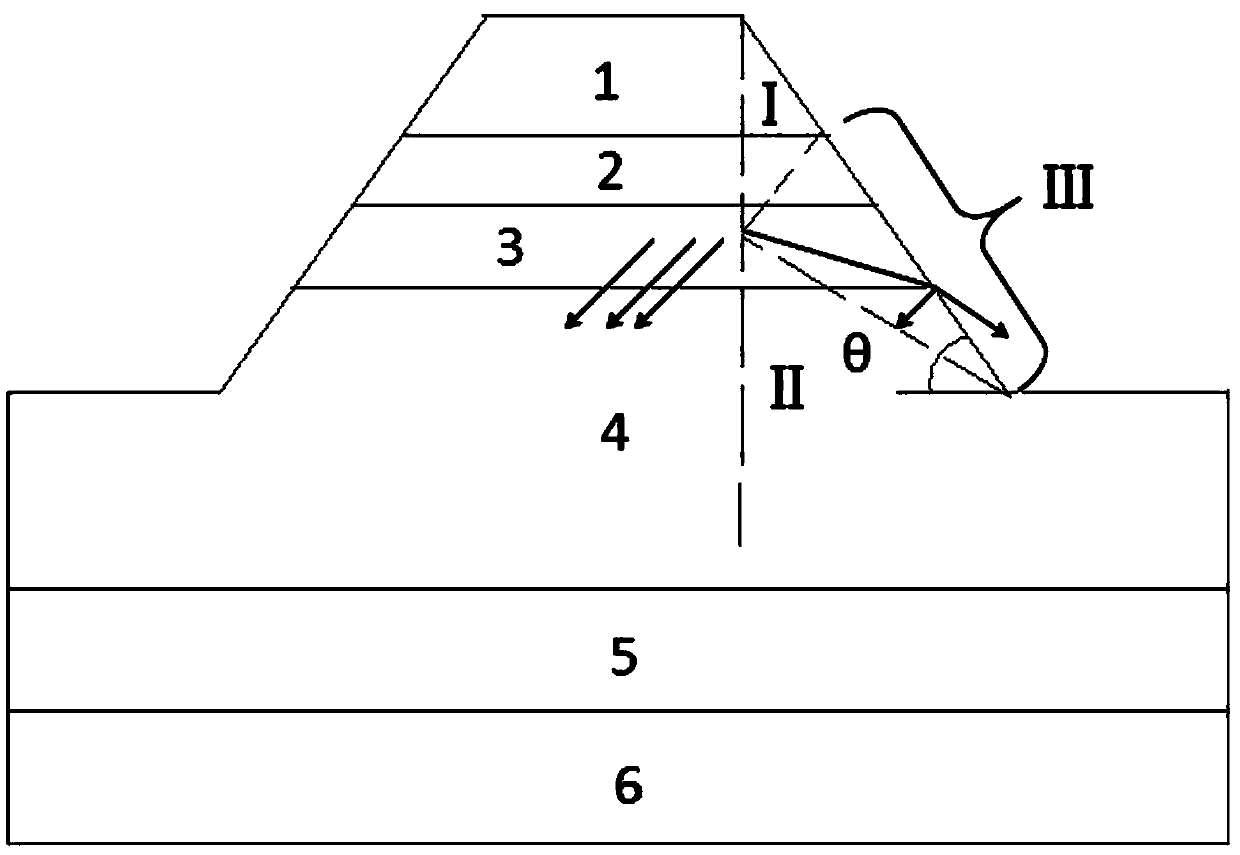

[0039] Such as Figure 1-3 As shown, an epitaxial structure of a deep ultraviolet LED chip, including a P-type GaN layer 1, a P-type AlGaN layer 2, a multi-quantum well active layer 3, an N-type AlGaN layer 4, an AlN layer 5 and a sapphire substrate connected in sequence 6. The multi-quantum well active layer 3 and the N-type AlGaN layer 4 jointly form an adjustment layer, and the adjustment layer has at least one inclined side, and the sandwich between the inclined side and the horizontal section near the center side of the adjustment layer The angle is the included angle of mesa etching, and the included angle of mesa etching is 28 degrees.

[0040]The adjustment layer has a plurality of inclined sides, and the mesa etching angles corresponding to the plurality of inclined sides are all 28 degrees.

[0041] The sloped sides include a first sloped side disposed on the multi-quantum well active layer 3 and a seco...

Embodiment 2

[0054] 1. Epitaxial structure of a deep ultraviolet LED chip

[0055] Such as Figure 1-3 As shown, an epitaxial structure of a deep ultraviolet LED chip, including a P-type GaN layer 1, a P-type AlGaN layer 2, a multi-quantum well active layer 3, an N-type AlGaN layer 4, an AlN layer 5 and a sapphire substrate connected in sequence 6. The multi-quantum well active layer 3 and the N-type AlGaN layer 4 jointly form an adjustment layer, and the adjustment layer has at least one inclined side, and the sandwich between the inclined side and the horizontal section near the center side of the adjustment layer The angle is the included angle of mesa etching, and the included angle of mesa etching is 35 degrees.

[0056] The adjustment layer has a plurality of inclined sides, and the mesa etching angles corresponding to the plurality of inclined sides are all 35 degrees.

[0057] The sloped sides include a first sloped side disposed on the multi-quantum well active layer 3 and a sec...

Embodiment 3

[0070] 1. Epitaxial structure of a deep ultraviolet LED chip

[0071] Such as Figure 1-3 As shown, an epitaxial structure of a deep ultraviolet LED chip, including a P-type GaN layer 1, a P-type AlGaN layer 2, a multi-quantum well active layer 3, an N-type AlGaN layer 4, an AlN layer 5 and a sapphire substrate connected in sequence 6. The multi-quantum well active layer 3 and the N-type AlGaN layer 4 jointly form an adjustment layer, and the adjustment layer has at least one inclined side, and the sandwich between the inclined side and the horizontal section near the center side of the adjustment layer The angle is the included angle of mesa etching, and the included angle of mesa etching is 40 degrees.

[0072] The adjustment layer has a plurality of inclined sides, and the mesa etching angles corresponding to the plurality of inclined sides are all 40 degrees.

[0073] The sloped sides include a first sloped side disposed on the multi-quantum well active layer 3 and a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com