Test method for communication and response delay between main control PLC and converter

A test method and converter technology, applied in electrical testing/monitoring, testing/monitoring control systems, instruments, etc., can solve problems such as inability to accurately judge response delays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

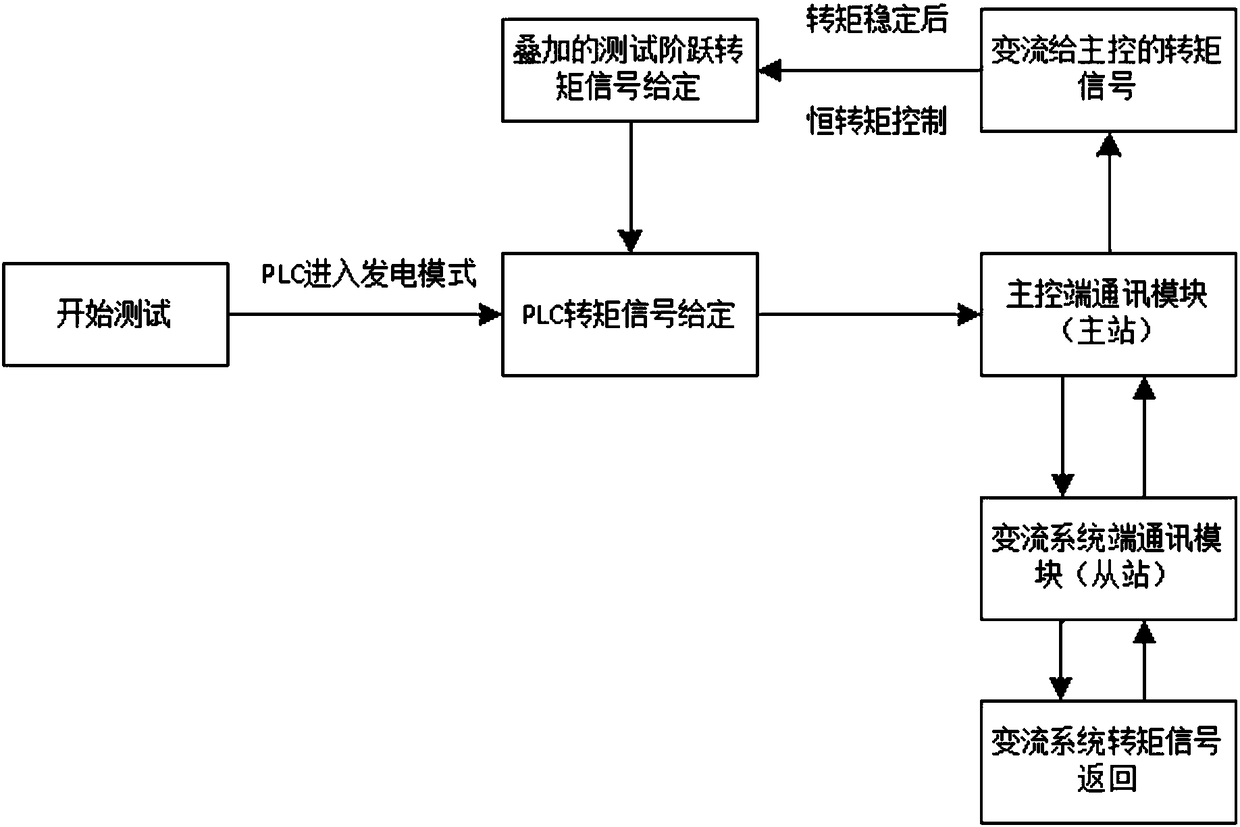

[0016] as the picture shows, figure 1 It is a flow chart of the present invention, a test method for communication and response delay between the main control PLC and the converter, wherein, the wind turbine starts and enters the power generation mode; according to the wind condition, the power of the wind turbine is limited to the pitch angle of A set value, the fan is in the full power state under the limited power; the fan control mode is constant torque control; by giving a step signal to the converter, the fan is superimposed with an additional torque value; record the excitation of the step signal and feedback delay to obtain the communication and response delay of the converter.

[0017] Further, the PLC controls the converter through the communication module so that the fan control mode is constant torque control.

[0018] Further, the communication module includes a master control terminal communication module communicating with the PLC and a converter terminal commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com