A water drop angle tester and test method

A test method and tester technology, which are applied to instruments, measuring devices, scientific instruments, etc., can solve the problems of inaccurate placement of test pieces, inaccurate angles of dripping liquid, inaccurate test results, etc., and achieve test accuracy. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

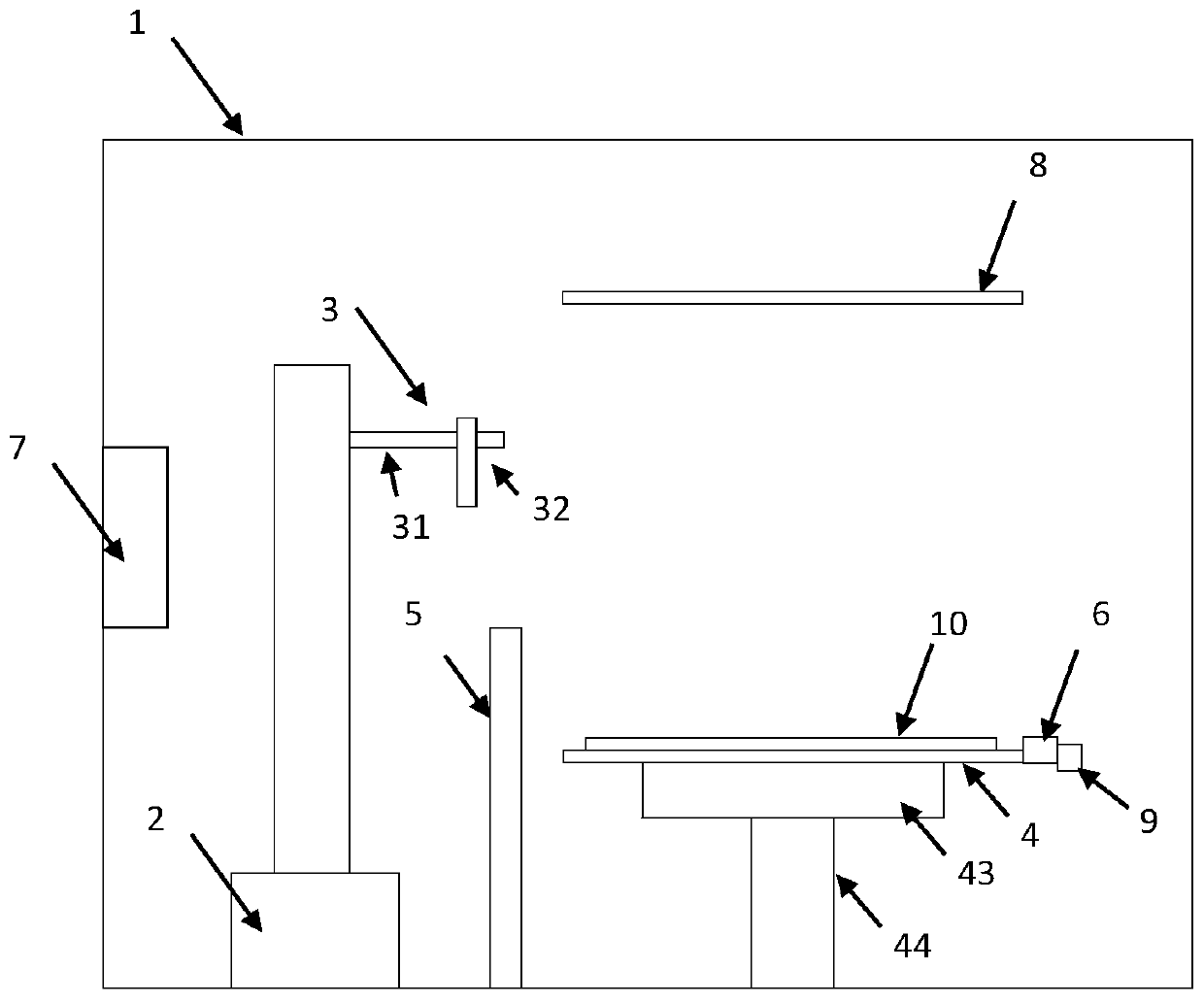

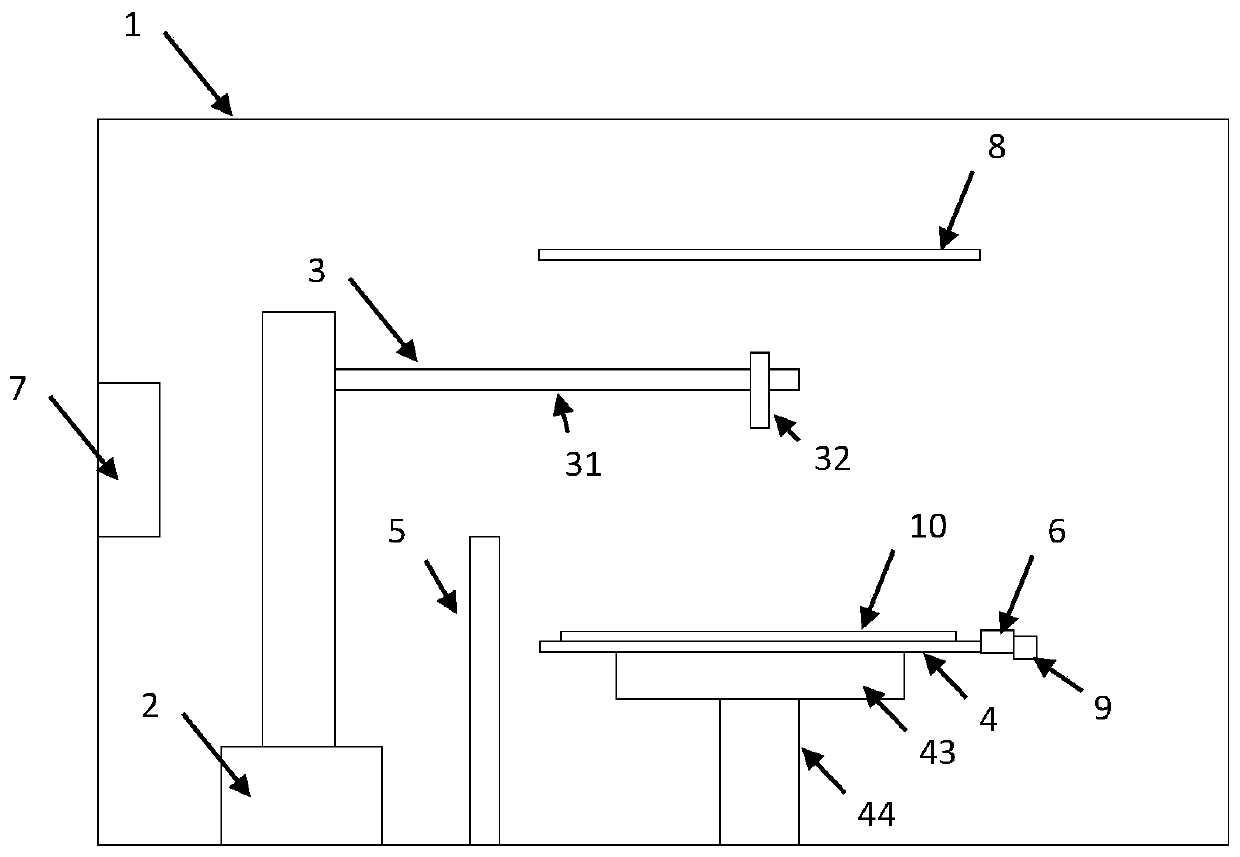

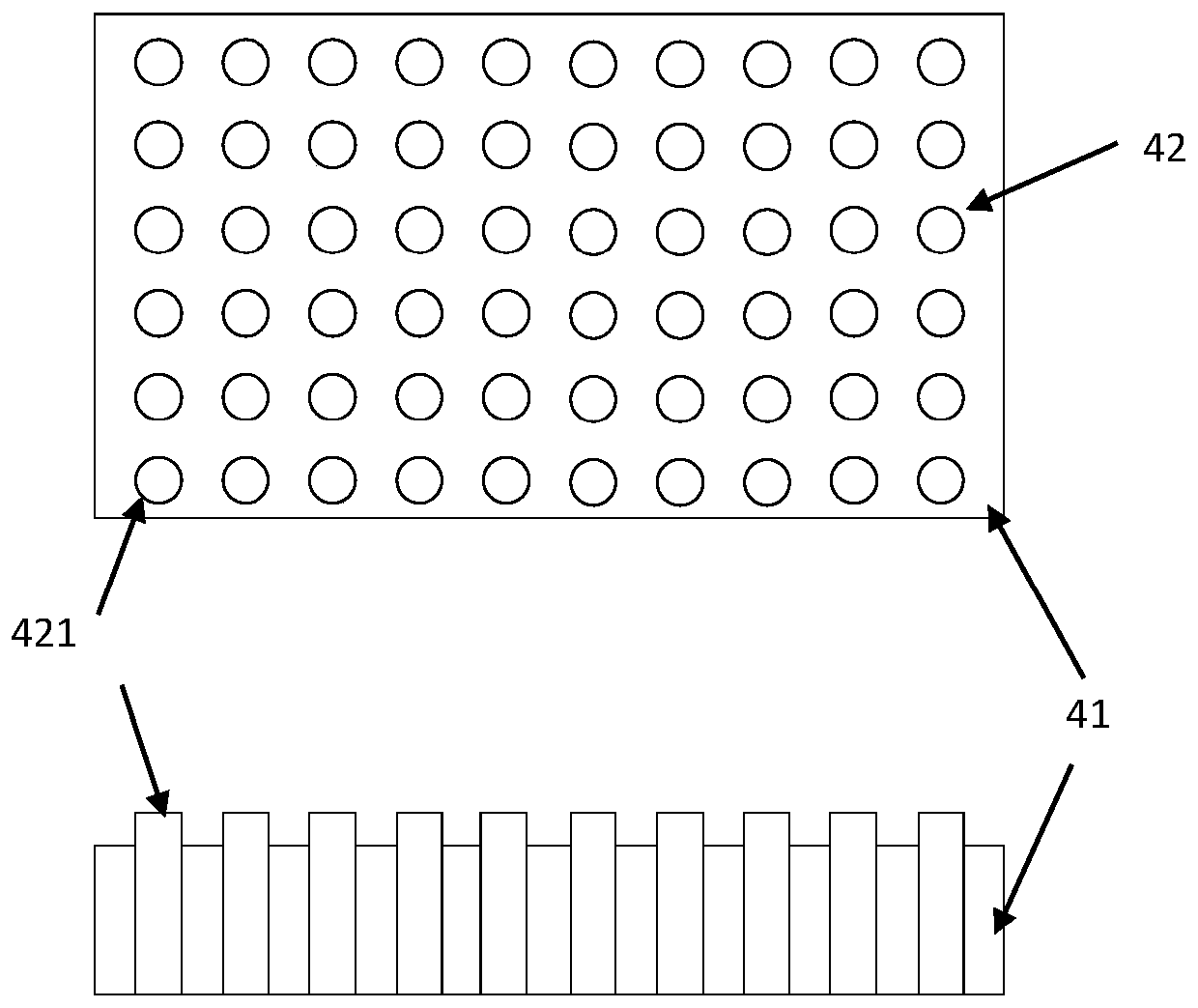

[0045] The water drop angle tester of the present invention is as Figure 1 to Figure 5 As shown, the water drop angle tester includes a housing 1, a storage part 2 for storing the test liquid, a drip part 3 communicating with the storage part 2, a platform part 4 for placing a test specimen 10, and a water drop angle tester. The illumination unit 5 of the light source, the imaging unit 6 for recording test images, the temperature control unit 7 for controlling the internal temperature of the water drop angle tester, and the processing unit (not shown) for processing the images transmitted by the imaging unit 6 and the signals of the water drop angle tester. Wherein, the storage part 2, the liquid dripping part 3, the platform part 4, the illumination part 5, the imaging part 6, the temperature control part 7 and the processing part are all fixed inside the housing 1; On the test specimen 10; the platform part 4 includes a sample stage 41, a fine-tuning device 42, a moving dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com