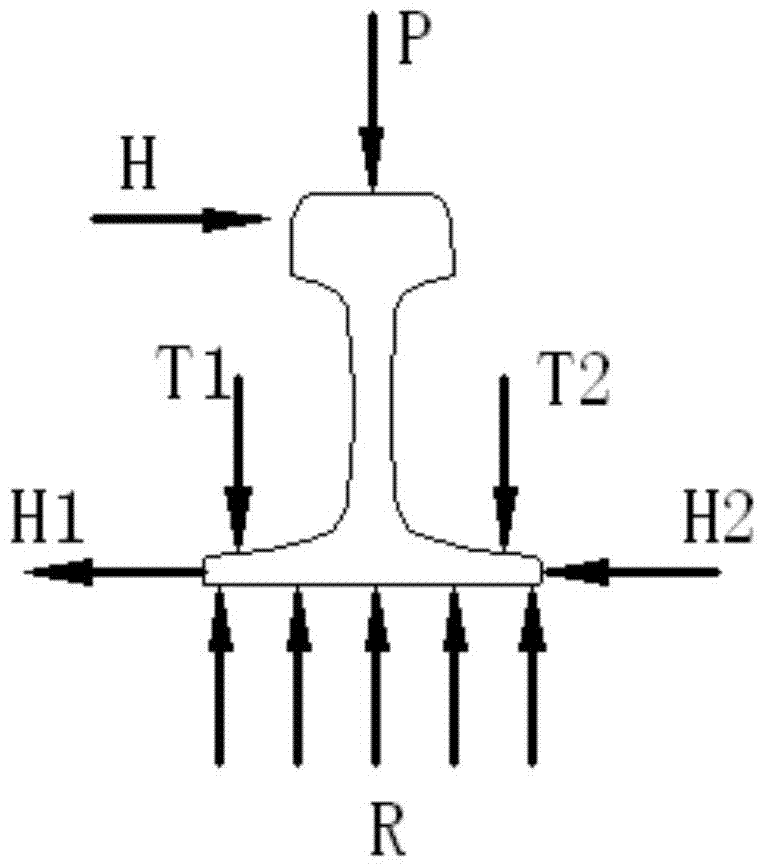

Comprehensive test method and device for wheel-rail force

A technology of comprehensive testing and wheel-rail force, applied in transportation and packaging, railway vehicle shape measuring devices, railway car body parts, etc., can solve the problems of low measurement accuracy and complicated operation of the measurement process, achieve high test accuracy and solve test problems Low precision and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

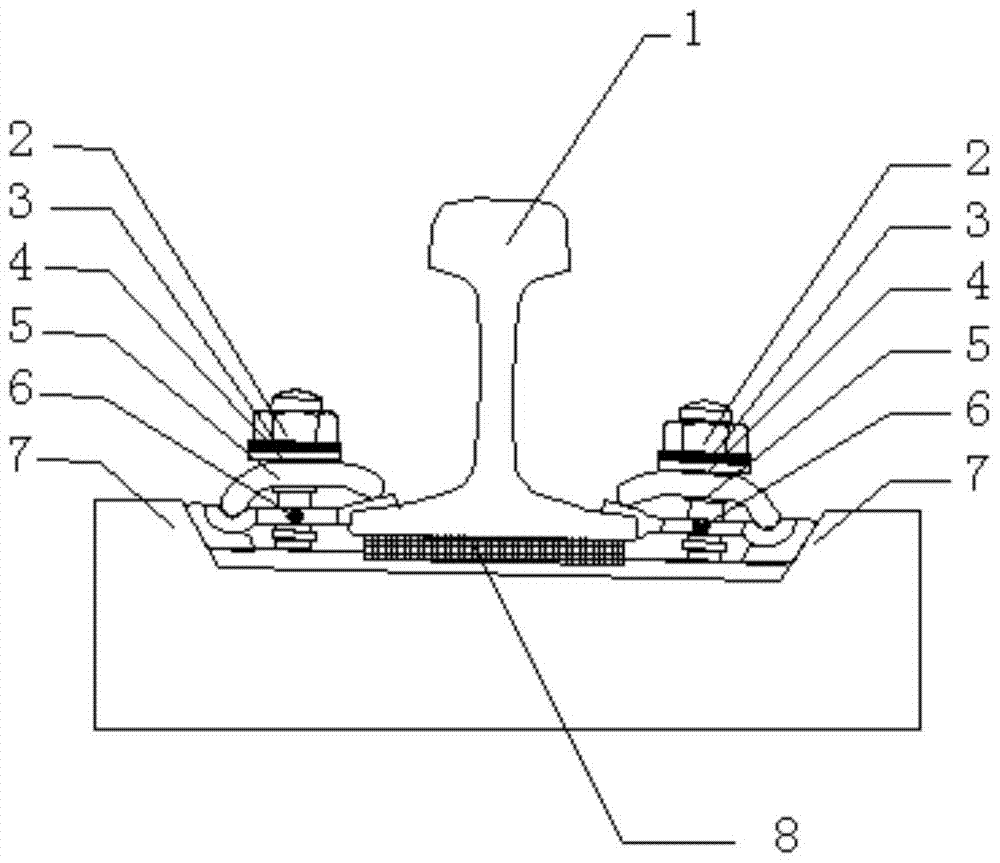

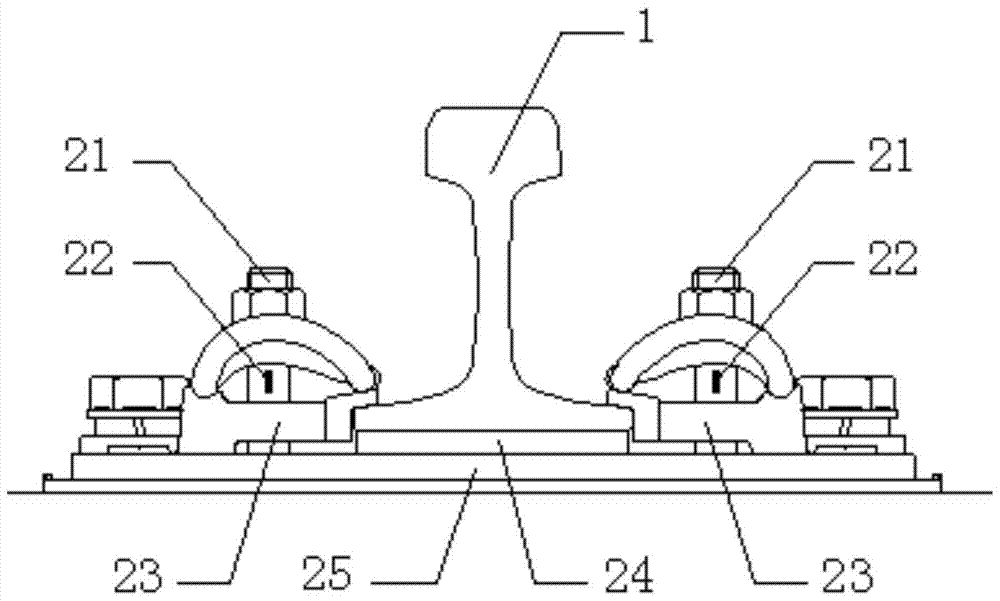

[0021] In order to have a clearer and more comprehensive understanding of the features, effects and technical objectives of the wheel-rail force comprehensive testing method of the present invention, further detailed descriptions are given below with reference to the accompanying drawings and specific embodiments.

[0022] like Figure 4 As shown in the step diagram of the wheel-rail comprehensive test method of the present invention, the wheel-rail comprehensive test method in an embodiment of the present invention includes the steps:

[0023] Step S101, setting a first vertical force sensor and a second vertical force sensor;

[0024] In this step, the specific setting method of the first vertical force sensor 8 is as follows: figure 2 , 5 As shown, the first vertical force sensor 8 is embedded in the middle of the support pad 25 of the assembly fastener 10, the fastener 10 is fixed on both sides of the rail 1, the rail 1 is fixed in the middle of the support pad 25, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com