Vector beam electrically-controlled generation device

A technology for generating devices and light beams, which is applied in the field of optics, can solve problems such as wasting time and energy, low conversion efficiency, and slow speed, and achieve the effects of avoiding time and energy waste, improving conversion efficiency, and avoiding segmentation phenomena

Pending Publication Date: 2018-12-28

HUNAN UNIV

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

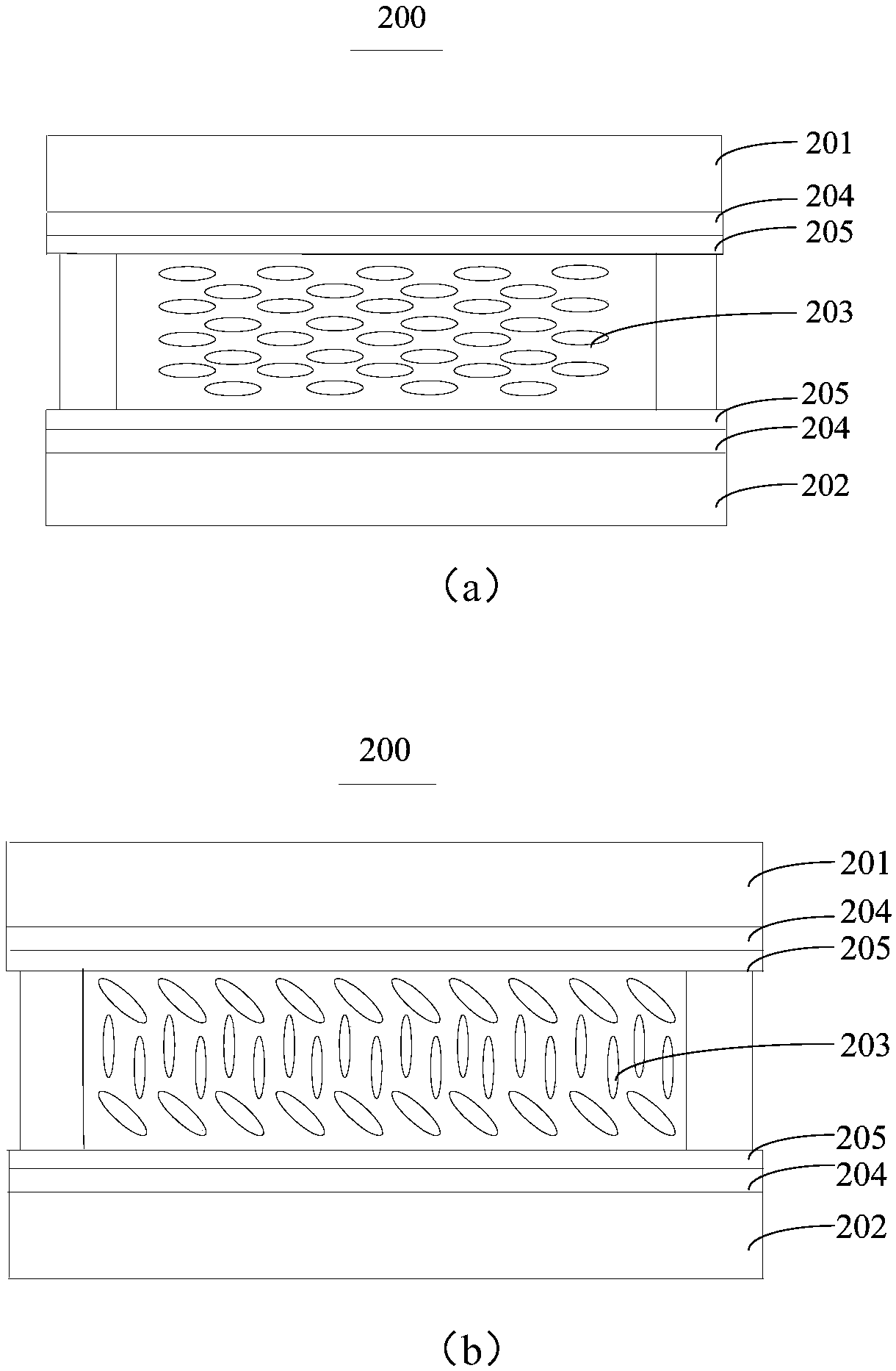

In the existing technology, the q-plate is generally divided into 12 parts on average, and the fast axis direction of each part is fixed, so the fast axis direction of the q-plate is segmented, thus affecting the spot quality of the outgoing light

And because the liquid crystal unit cannot be made small enough, the diffraction phenomenon cannot be effectively suppressed, resulting in low conversion efficiency

In traditional devices that generate vector beams, it is often necessary to manually adjust or replace the wave plate, which is not only slow but also cumbersome, wasting a lot of time and energy

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Login to View More

Abstract

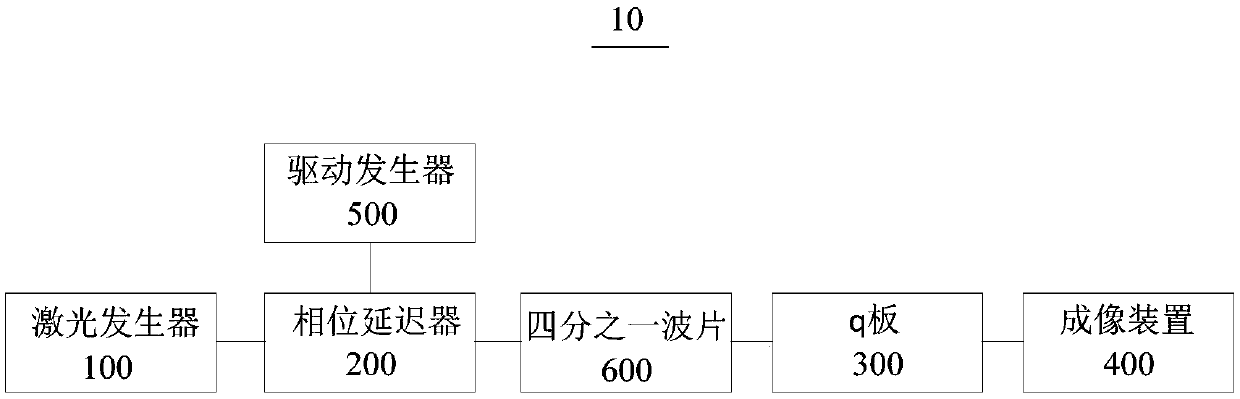

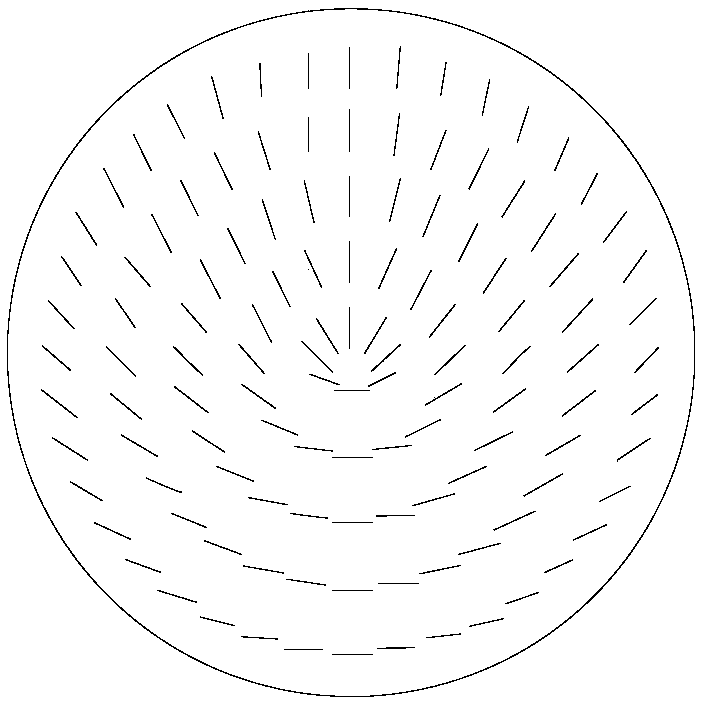

The embodiment of the invention provides a vector beam electrically-controlled generation device which comprises a laser generator, a phase delayer, a q board and an imaging device,wherein the laser generator generates incident laser; the phase delayer is arranged at the light emergent side of the laser generator for carrying out phase delaying processing on the incident laser; the q board is usedfor carrying out vector polarization processing on a beam subjected to phase delaying processing; the imaging device is arranged at the light emergent side of the q board and is used for presenting alight spot formed on the imaging device by light emerging from the q board; the q board is formed by utilizing femtosecond laser to etch a micro-nano structure on a glass board; and the micro-nano structure on the q board shows a shape continuously changed along with a polar angle in a direction of a fast axis of the micro-nano structure. By design of the micro-nano structure on the q board, a segmented phenomenon is avoided, and quality of emergent light is improved. Moreover, due to additional arrangement of the phase delayer, phase delaying processing can be changed by regulating a size ofa voltage so as to avoid waste of time and effort, which is caused by manual regulation or replacement of a wave plate in the prior art.

Description

technical field The invention relates to the field of optical technology, in particular to an electronically controlled generating device for vector beams. Background technique The q-plate (q-plate) is a non-uniform anisotropic medium that arranges tiny liquid crystal cells in a specific geometric pattern. Its structure changes with the change of the azimuth angle. The direction of the optical axis of a uniaxial crystal changes, so the q-plate can be regarded as a spatially non-uniformly distributed phase retarder or wave plate whose fast axis changes with the azimuth angle. Modulation of polarization state of light field. In recent years, due to the spin-orbital angular momentum conversion in the q-plate, it has great applications in generating vortex beams. The general device for generating vector beams uses a laser to generate a Gaussian beam, then controls the polarization state of the incident light through a laser polarizer and a wave plate, and then passes through a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02F1/01G02F1/13363

CPCG02F1/0136G02F1/13363G02F1/133638

Inventor 王瑞斯罗海陆

Owner HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com