Gas sensor with gas chromatographic analysis function

A gas chromatographic analysis and gas sensor technology, applied in the direction of analytical materials, instruments, scientific instruments, etc., can solve the problems of increased operating costs, more auxiliary equipment, long detection cycle, etc., and achieves reduced demand, less auxiliary equipment, and improved quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

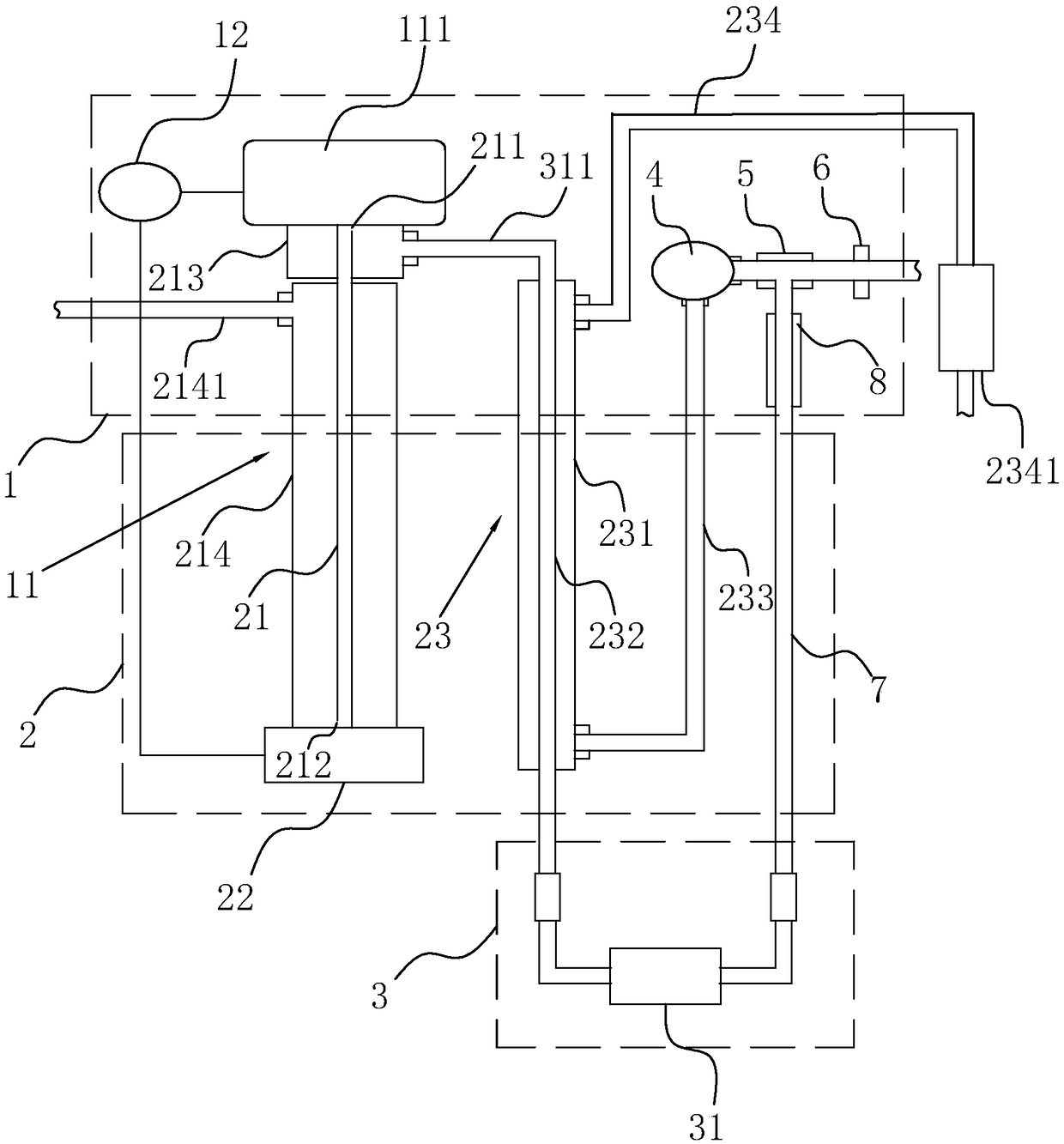

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings, wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower", "bottom" and "top" used in the following description refer to the Directions, the words "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

[0033] A gas sensor with gas chromatographic analysis function, such as figure 1 As shown, it includes a degassing device for separating the gas in the drilling fluid, a gas detection device 11 connected with the degassing device for gas chromatography analysis, and a gas detector 11 for driving the gas in the degassing device into the gas detection device 11. road drive. Wherein, the degassing device is set as a gas-liquid separation cavity 31 closed by an oil-gas separation semi-permeable m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com