Continuous-working defrosting device for quick-freeze storage

A quick-freezing storage and working technology, applied in defrosting, household refrigeration equipment, household appliances, etc., can solve the problems of high processing cost, long time, inconvenient maintenance, etc., and achieve the effect of reliable operation, convenient maintenance and compact structure

Pending Publication Date: 2018-12-28

SIFANG TECH GRP CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there are patents that mention the screw drive and the sprocket as the transmission mechanism of the air jet groove, but it is not mentioned that it is suitable for an ultra-long evaporator, and the spare switch for controlling the direction of the air jet groove is troublesome to make and inconvenient to maintain.

Generally, the quick-freezing warehouse needs to be shut down for frosting and cleaning after working for a certain period of time. The special quick-freezing warehouse needs to work continuously for 6 days, and the screw is used as the transmission mechanism of the air jet groove. Too long, high processing cost

The surface of the evaporator needs to be blown dry after the water in the quick-freezing warehouse that works continuously is frosted. The traditional method is to turn on the fan to blow dry, which consumes a lot of energy and takes a long time.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

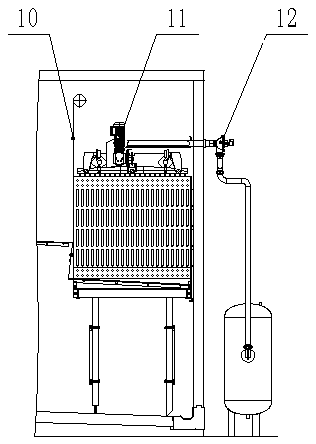

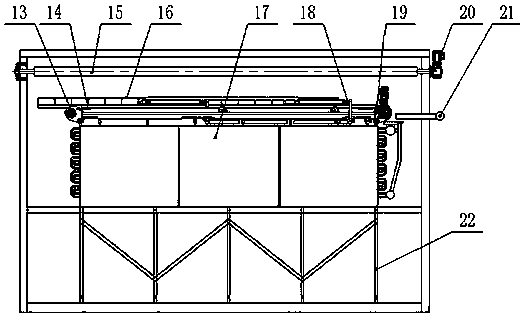

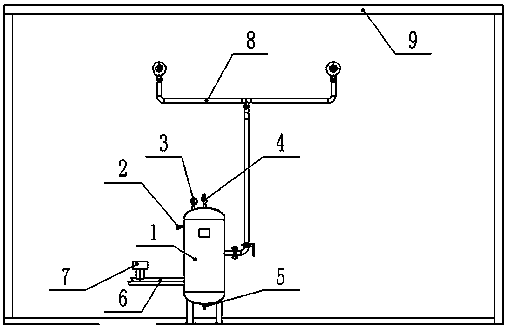

The invention relates to a continuous-working defrosting device for a quick-freeze storage. The continuous-working defrosting device comprises a compressed-air defrosting component, a thermal-insulation storage body, an air injection tank component, an air injection tank component reversing transmission mechanism, a water defrosting system and an automatic water retaining device and is characterized in that the compressed-air defrosting component comprises an air storage tank, the lower end of the air storage tank is provided with an automatic water discharge valve, and the upper end of the air storage tank is provided with a pressure gauge, a safety valve and a pressure transmitter. The continuous-working defrosting device has the advantages that the device is especially suitable for a super-long evaporator, low-pressure compressed air is used for performing blow drying after defrosting, nozzles are close to the evaporator, fast blow drying is achieved, the large-flow rotary nozzles are mounted on the guide rail of the air injection tank component, structure compactness is achieved, air injection tank reversing uses a special double-proximity-switch control manner, work reliability and maintenance convenience are achieved, and the automatic-control water retaining device is used during evaporator water defrosting to prevent low-temperature discharge water from splashing aroundto cause mesh belt icing.

Description

technical field The invention relates to a defrosting and defrosting device for a continuous working quick-freezing store. Background technique At present, there are patents that mention the screw drive and the sprocket as the transmission mechanism of the air jet groove, but it is not mentioned that it is suitable for an ultra-long evaporator, and the spare switch for controlling the direction change of the air jet groove is troublesome to make and inconvenient to maintain. Generally, the quick-freezing warehouse needs to be shut down for frosting and cleaning after working for a certain period of time. The special quick-freezing warehouse needs to work continuously for 6 days, and the screw is used as the transmission mechanism of the air jet groove. It is too long, and the processing cost is high. The surface of the evaporator needs to be blown dry after the water in the quick-freeze storage that works continuously is frosted. The traditional method is to turn on the fa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F25D21/06

CPCF25D21/06

Inventor 杨长春钱丹朱金祥朱晓林徐翔锋

Owner SIFANG TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com