Method for alkaline flocculation harvesting and circulation culture of microalgae

A technology of circular culture and microalgae cultivation, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of reducing microalgae revenue, microalgae cultivation reactor amplification, microalgae growth limitation, etc., to achieve Reduce the cost of microalgae cultivation, reduce the cost of carbon source supply, and avoid the effect of continuous infusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

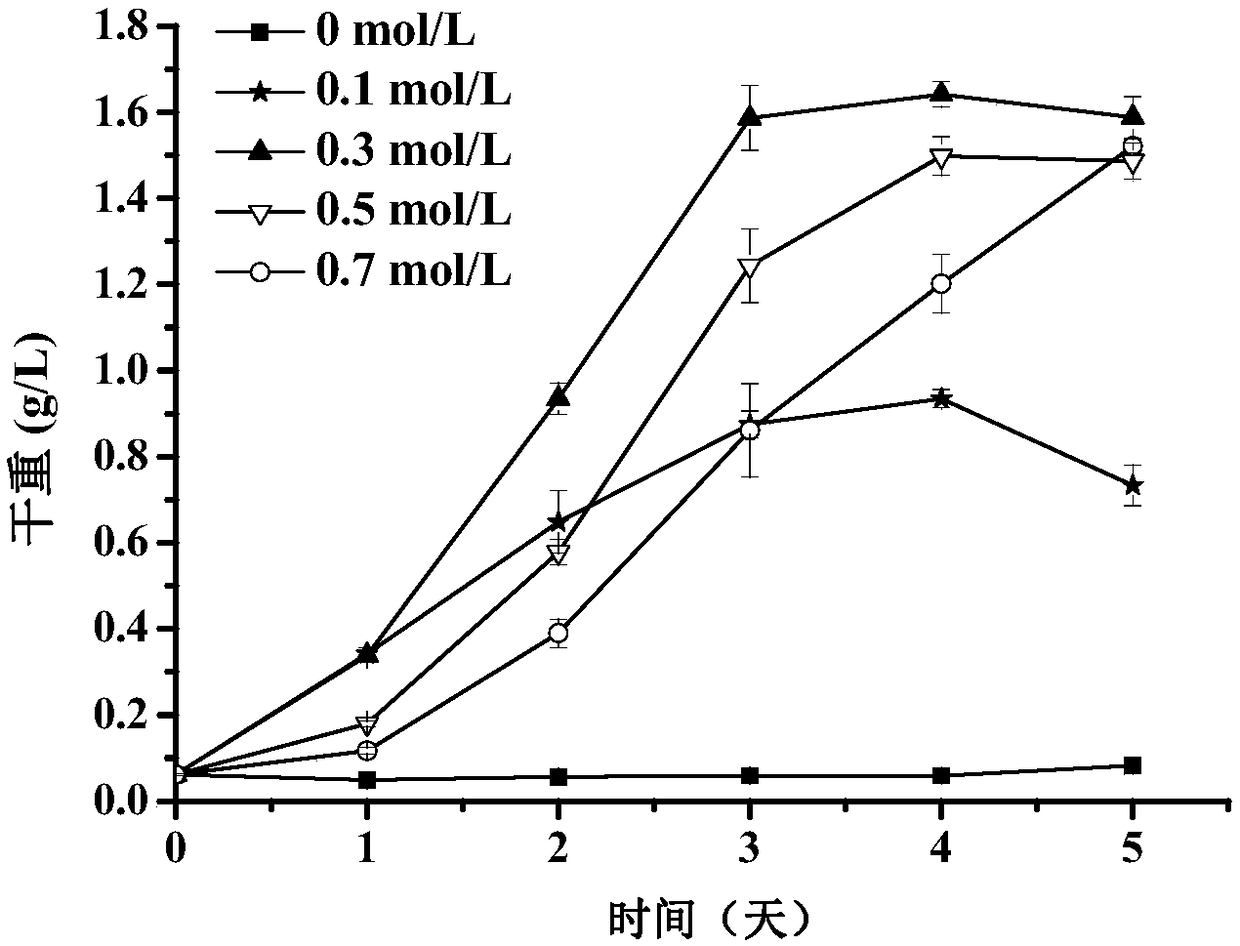

[0048] Embodiment 1: the influence of different concentrations of sodium bicarbonate on the growth of oil-rich new green algae

[0049] First, explore the effects of different concentrations of sodium bicarbonate on the growth of oil-rich neochloroalgae. The concentration of sodium bicarbonate is set to 0, 0.1, 0.3, 0.5, 0.7 mol / L, and the composition and content of other nutrients remain the same. For details, see the formula in Table 1 , Table 2. The culture system is a 1L Erlenmeyer flask, the culture volume is 400mL, the inoculation density is 0.05g / L, and the light intensity is 141.5μmol / m 2 · s, the temperature is 25° C., and the culture time is 5 days.

[0050] Experimental results such as figure 1 As shown, after being cultured in medium containing different concentrations of sodium bicarbonate for 5 days, its biomass concentration reached 0.083g / L, 0.91±0.04, 1.64±0.03, 1.50±0.05 and 1.52±0.02g / L respectively, of which 0.3 The biomass of mol / L sodium bicarbonate ex...

Embodiment 2

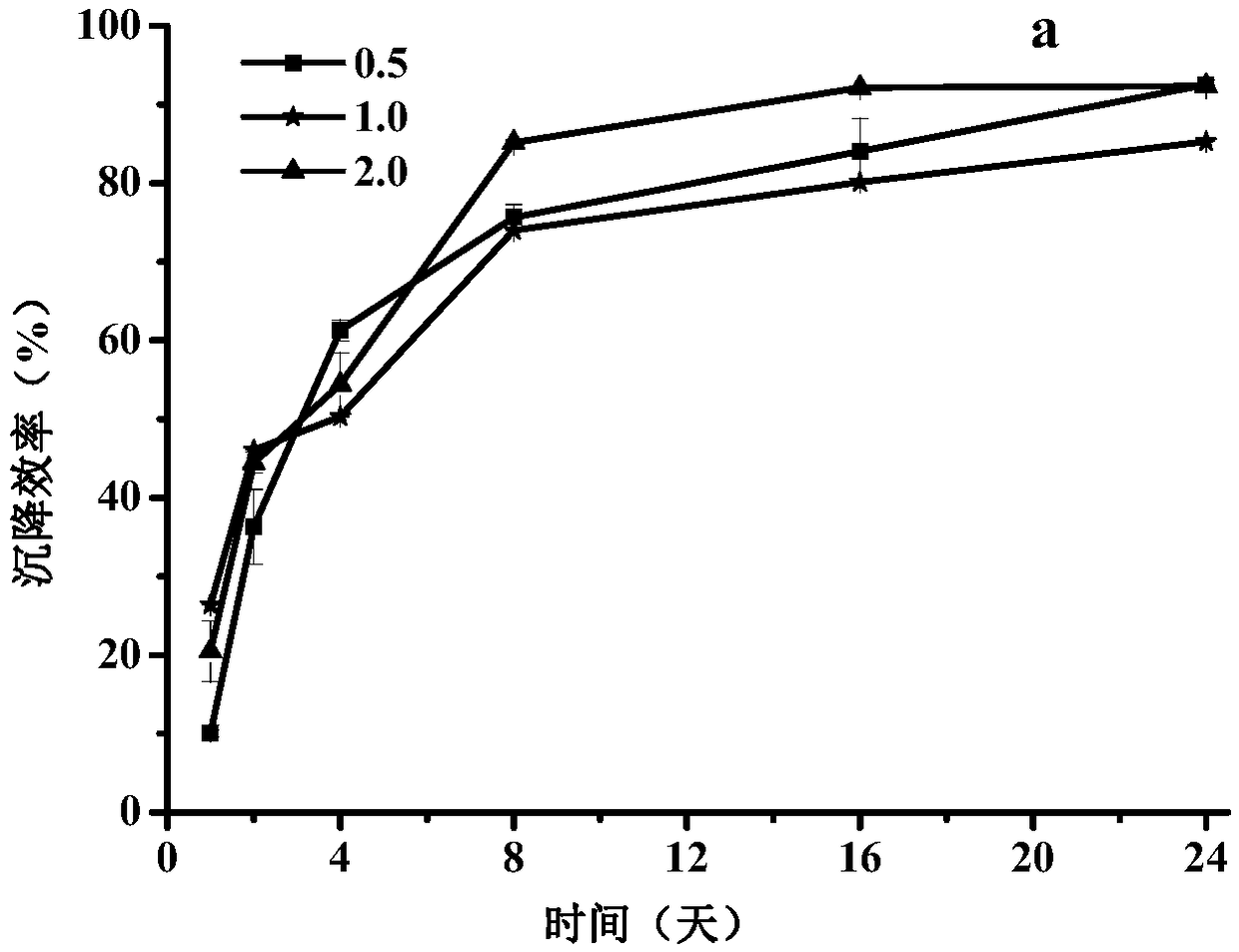

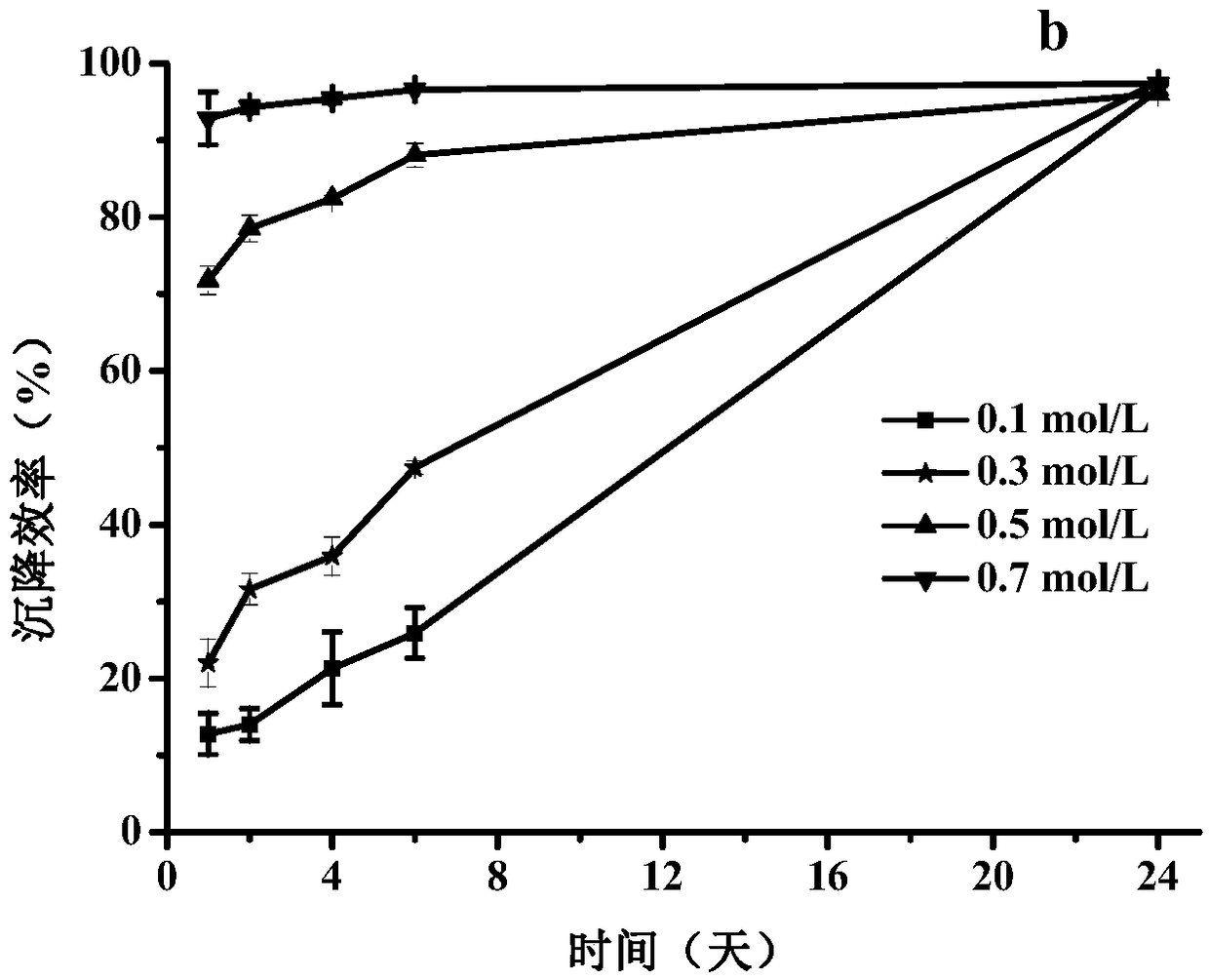

[0055] Example 2: Self-flocculation of oil-rich Neochlorella under alkaline conditions

[0056] In the process of microalgae cultivation, the bicarbonate in the medium is consumed, resulting in a highly alkaline environment, which can efficiently recover microalgal biomass without adding any flocculants, and does not produce any Biomass pollution. Therefore, the oil-rich neogreen algae cultured at the optimum sodium bicarbonate concentration (0.3mol / L) were harvested by centrifugation first, and the algae were washed several times with 0.5mol / L NaCl solution, and redissolved in the initial fresh medium with pH 10.0 The resuspended algae solution with cell concentration of 0.5, 1.0 and 2.0 g / L was obtained, and transferred to a 50 mL pre-dried graduated cylinder, and allowed to settle for 24 hours. In addition, this example also explored the influence of different concentrations of sodium bicarbonate (0.1, 0.3, 0.5, 0.7 mol / L) on self-flocculation.

[0057] Such as figure 2...

Embodiment 3

[0059] Example 3: Alkaline flocculation of oil-rich neochloroalgae at different calcium ion concentrations

[0060] In order to investigate the effect of calcium ion concentration on the flocculation and sedimentation of oil-rich Neochlorella, the oil-rich Neochlorella in the logarithmic growth phase was harvested by centrifugation, washed with 0.5mol / L NaCl solution for several times, and redissolved in the initial fresh culture at pH 10.0. Base, and set the cell concentration to 0.5g / L. Add 40mL of resuspended algae solution into a 250mL conical flask, then place the conical flask on a stirrer, stir the algae solution at a speed of 1000rpm, and mix different concentrations of CaCl 2 (5, 10, 15 and 20mmol / L) were slowly added to the culture medium, stirred for 10 minutes, then stirred at a speed of 250rpm for 20 minutes, transferred to a 50mL pre-dried measuring cylinder, left to settle for 24 hours, and the absorbance value A was measured. 750 .

[0061] The result is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com