Graphene antistatic floor paint and preparation method thereof

A technology of graphene and floor paint, applied in the field of floor paint, can solve the problems of poor electrical conductivity of floor paint, reinforcement, and easy agglomeration of graphene, so as to enhance antistatic performance, solve spontaneous agglomeration, and avoid interlayer gaps The effect of reducing the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

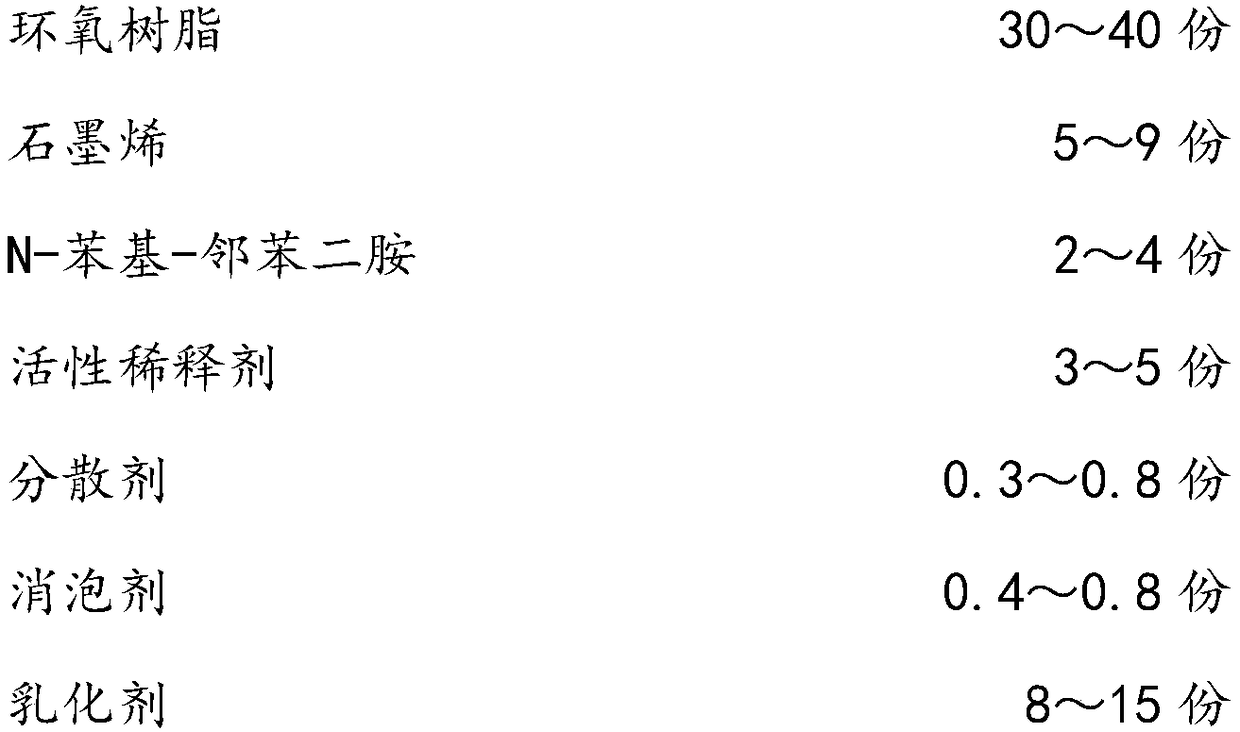

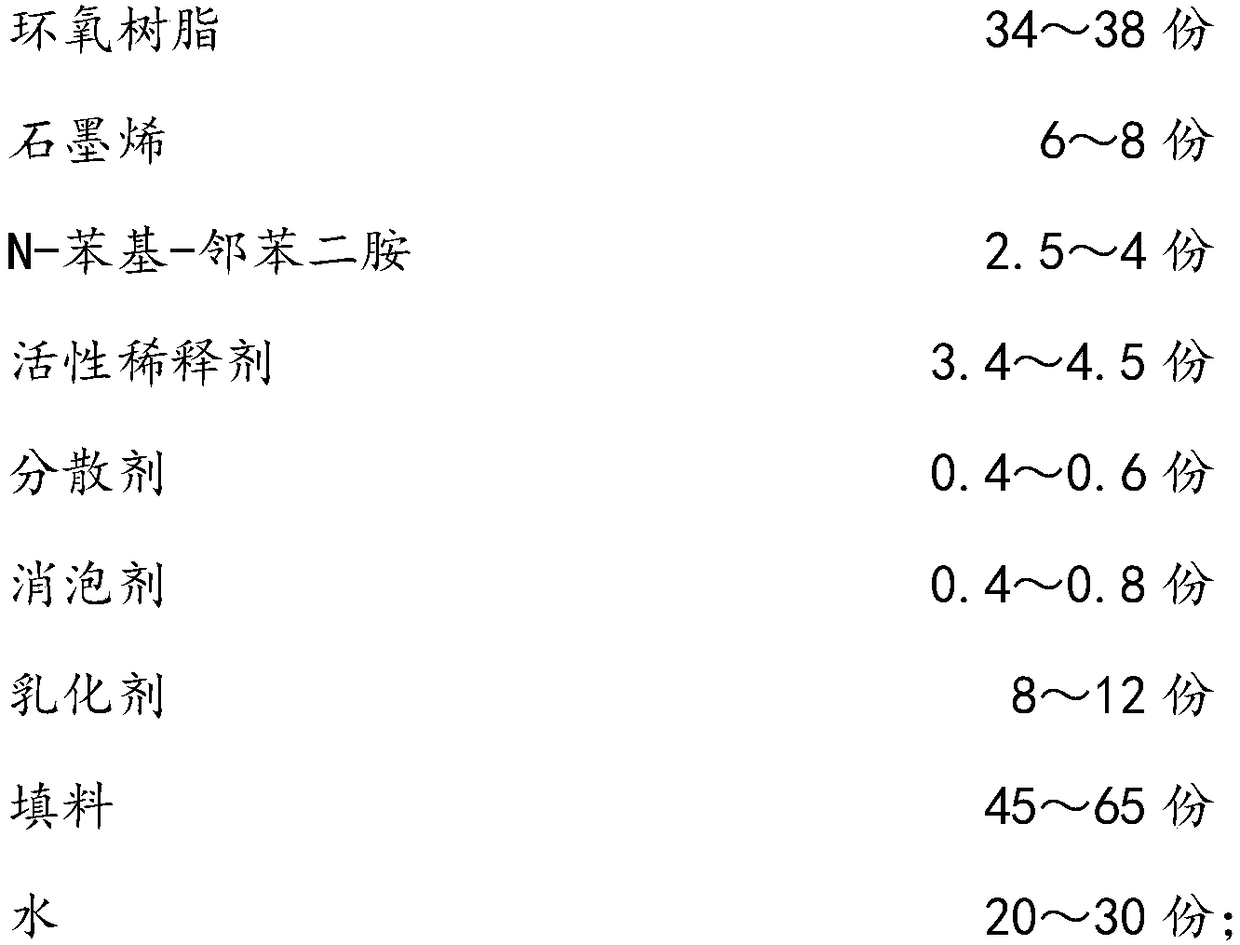

Method used

Image

Examples

Embodiment 1

[0056] A component preparation:

[0057] Step 1. Mix 35 parts of epoxy resin, 0.6 part of dispersant and 9 parts of emulsifier with 18 parts of water, and stir for 60 minutes at a speed of 550 rpm;

[0058] Step 2. Dissolve 6.8 parts of graphene in 7 parts of water, ultrasonically shake for 30 minutes, then add the product of step 1 and 2.6 parts of N-phenyl-o-phenylenediamine, heat up to 65°C, and rotate at 1100 rpm After stirring for 40 minutes, add 0.5 parts of defoamer, 3.6 parts of reactive diluent and 48 parts of filler, continue stirring at 1500 rpm for 2 hours, cool down and discharge to obtain the product of component A;

[0059] Preparation of component B:

[0060] Add 9 parts of amino-modified graphene, 9 parts of pyromellitic dianhydride and 6 parts of acrylonitrile-diethylenetriamine compound into the container, and stir and mix for 50 minutes at a rate of 1000 rpm to obtain the group B sub-products.

Embodiment 2

[0062] A component preparation:

[0063] Step 1. Mix 35 parts of epoxy resin, 0.5 part of dispersant and 9.8 parts of emulsifier with 18 parts of water, and stir for 60 minutes at a speed of 550 rpm;

[0064] Step 2. Dissolve 7.2 parts of graphene in 8 parts of water, ultrasonically shake for 30 minutes, then add the product of step 1 and 2.6 parts of N-phenyl-o-phenylenediamine, raise the temperature to 65 ° C, at a speed of 1100 rpm After stirring for 40 minutes, add 0.4 parts of defoamer, 3.8 parts of reactive diluent and 55 parts of filler, continue stirring at 1500 rpm for 2 hours, cool down and discharge to obtain the product of component A;

[0065] Preparation of component B:

[0066] Add 10 parts of amino-modified graphene, 9 parts of pyromellitic dianhydride and 7 parts of acrylonitrile-diethylene triamine compound into the container, and stir and mix at a rate of 1000 rpm for 50 minutes to obtain the group B sub-products.

Embodiment 3

[0068] A component preparation:

[0069] Step 1. Mix 37 parts of epoxy resin, 0.5 part of dispersant and 10.7 parts of emulsifier with 19 parts of water, and stir for 60 minutes at a speed of 550 rpm;

[0070] Step 2. Dissolve 7.6 parts of graphene in 10 parts of water, ultrasonically shake for 30 minutes, then add the product of step 1 and 3.5 parts of N-phenyl-o-phenylenediamine, raise the temperature to 65 ° C, at a speed of 1100 rpm After stirring for 40 minutes, add 0.7 parts of defoamer, 4.2 parts of reactive diluent and 60 parts of filler, continue stirring at 1500 rpm for 2 hours, cool down and discharge to obtain the product of component A;

[0071] Preparation of component B:

[0072] Add 10 parts of amino-modified graphene, 10 parts of pyromellitic dianhydride and 8 parts of acrylonitrile-diethylene triamine compound into the container, stir and mix at a rate of 1000 rpm for 50 minutes, and then the Group B can be obtained sub-products.

[0073] Wherein, the embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com