Transformer bushing and manufacturing method thereof

A technology of transformer bushing and porcelain bushing, applied in transformer/inductor cooling, transformer/inductor parts, transformer/inductor coil/winding/connection, etc. , can not meet the needs of the use of transformer bushings, etc., to avoid excessive temperature and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing:

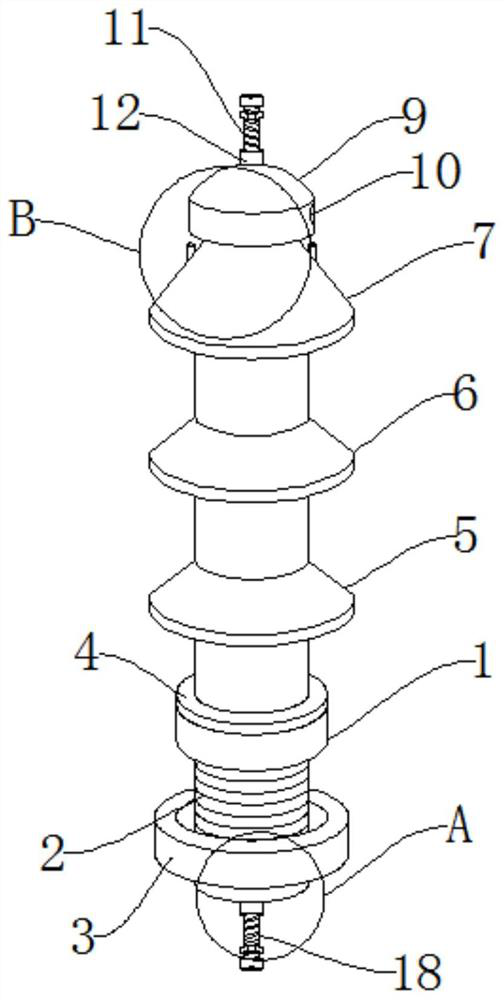

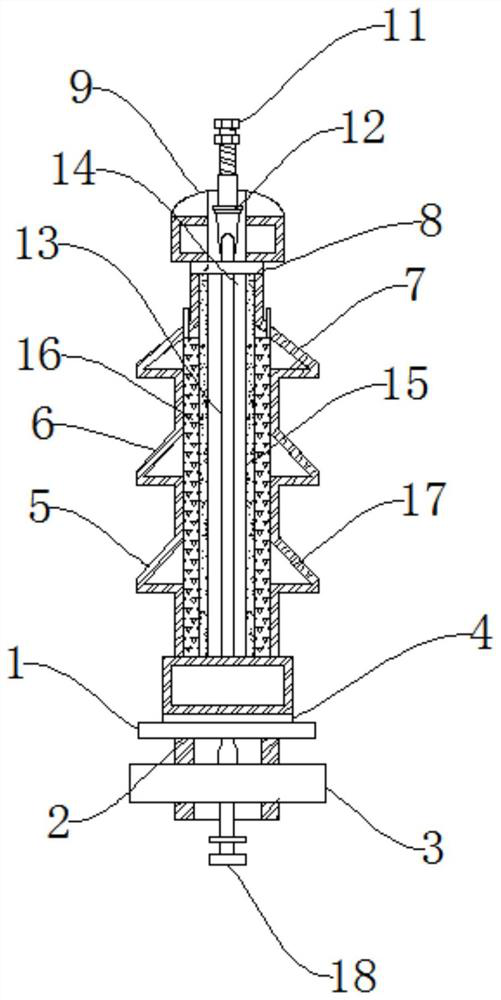

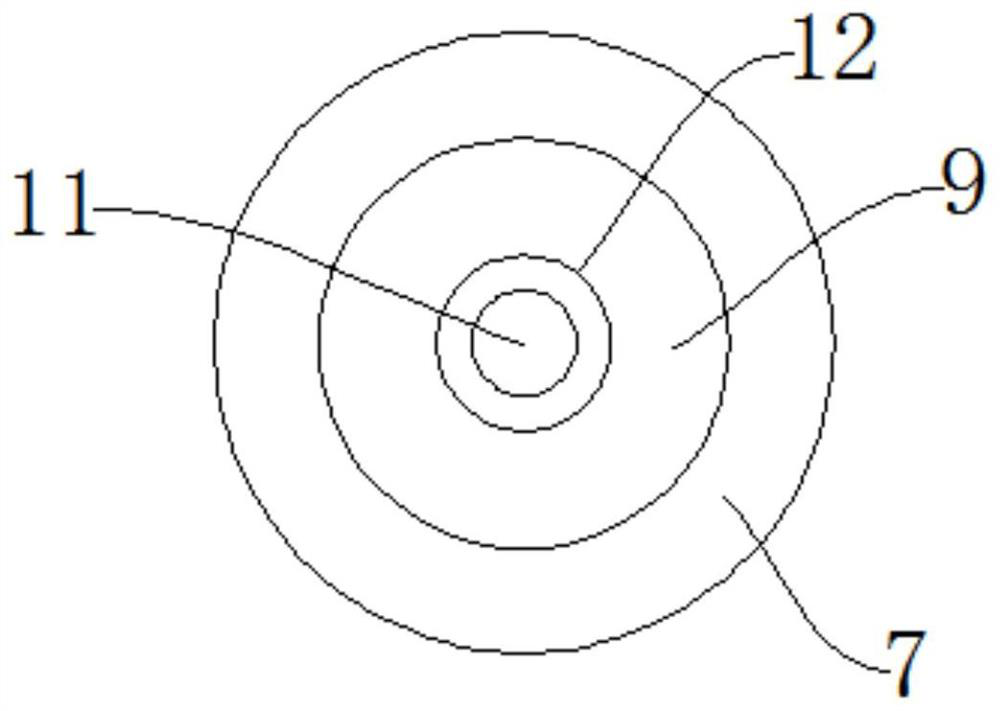

[0035] like Figure 1-Figure 5 As shown, a transformer bushing includes a base 1, a porcelain cap 9 and a high temperature resistant tube 15, the outer side of the base 1 is provided with a thread 2, and the outer side of the thread 2 is provided with an insulating sheath 3, through the insulating sheath 3, the transformer sleeve can be The bottom of the tube should be protected from moisture to avoid short-circuit burning in the transformer caused by moisture between the transformer bushing and the transformer. A gasket 4 is arranged above the insulating shell 3, and a porcelain sleeve 5 is arranged above the gasket 4. Through the porcelain sleeve 5, the Make the porcelain sleeve 2 6 firmly connected, the porcelain sleeve 2 6 is arranged above the porcelain sleeve 1 5, the porcelain sleeve 3 7 is arranged above the porcelain sleeve 2 6, the dustproof ring 8 is arranged abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com