Lightweight PC/ABS weight loss composite material and preparation method thereof

A composite material, lightweight technology, applied in the field of materials, can solve the problem of hollow glass microspheres being easily broken, and achieve the effects of excellent mechanical properties, maintaining integrity and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

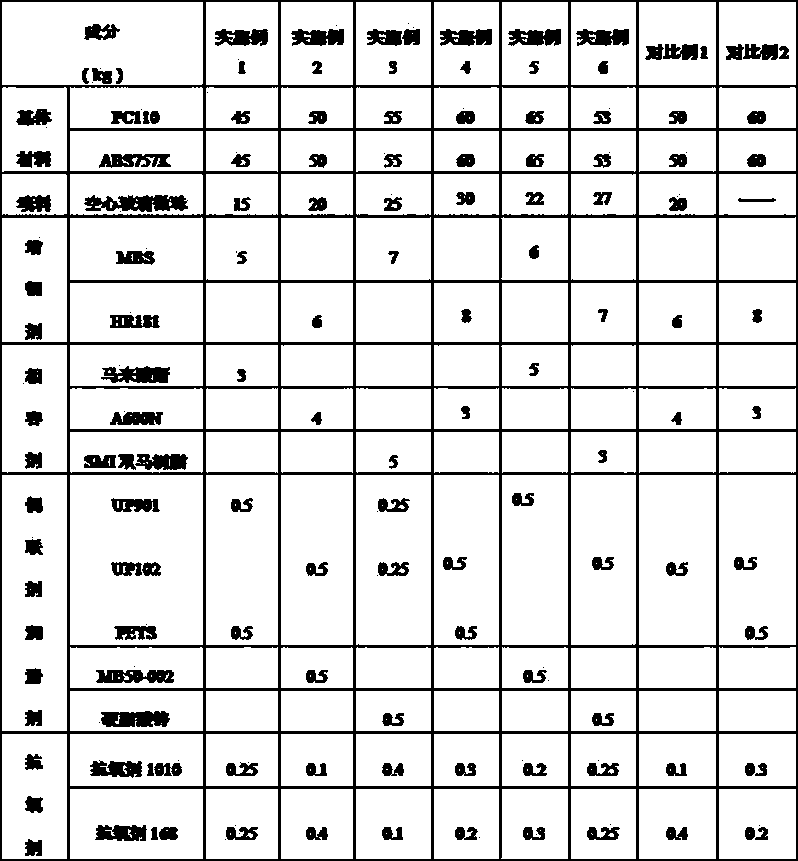

Embodiment 1

[0035] The formula composition of the lightweight PC / ABS weight-reducing composite material of this embodiment is as follows: PC110 45 kg, ABS757K 45 kg, hollow glass microspheres 15 kg, MBS 5 kg, maleic anhydride 3 kg, UP901 0.5 kg, PETS 0.5 kg, Antioxidant 1010 0.25 kg, Antioxidant 168 0.25 kg.

[0036] The preparation method of the weight-reducing composite material of this embodiment is prepared by referring to the above-mentioned method.

[0037] The performance evaluation method of the weight-reducing composite material of this embodiment is determined by referring to the above-mentioned evaluation method.

Embodiment 2

[0039] The formulation of the lightweight PC / ABS weight-reducing composite material in this example is as follows: PC110 50 kg, ABS757K 50 kg, hollow glass microspheres 20 kg, HR181 6 kg, A600N 4 kg, UP102 0.5 kg, MB 50-002 0.5 kg , antioxidant 1010 0.1 kg, antioxidant 168 0.4 kg.

[0040] The preparation method of the weight-reducing composite material of this embodiment is prepared by referring to the above-mentioned method.

[0041] The performance evaluation method of the weight-reducing composite material of this embodiment is determined by referring to the above-mentioned evaluation method.

Embodiment 3

[0043] The formulation of the lightweight PC / ABS weight-reducing composite material in this example is as follows: PC110 55 kg, ABS757K 55 kg, hollow glass microspheres 25 kg, MBS 7 kg, SMI double horse resin 5 kg, UP901 0.25 kg, UP102 0.25 kg , zinc stearate 0.5 kg, antioxidant 1010 0.4 kg, antioxidant 168 0.1 kg.

[0044] The preparation method of the weight-reducing composite material of this embodiment is prepared by referring to the above-mentioned method.

[0045] The performance evaluation method of the weight-reducing composite material of this embodiment is determined by referring to the above-mentioned evaluation method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com