Noise-reducing saw blade for timber cutting

A sound-absorbing, wood-based technology, applied in the direction of saw blades, circular saws, etc., can solve the problems that the saw blade is easy to cause fire, the life of the saw blade is easy to shorten, and the life of the saw blade is shortened, so that it is not easy to cause fire and the life of the saw blade is not easy to shorten Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

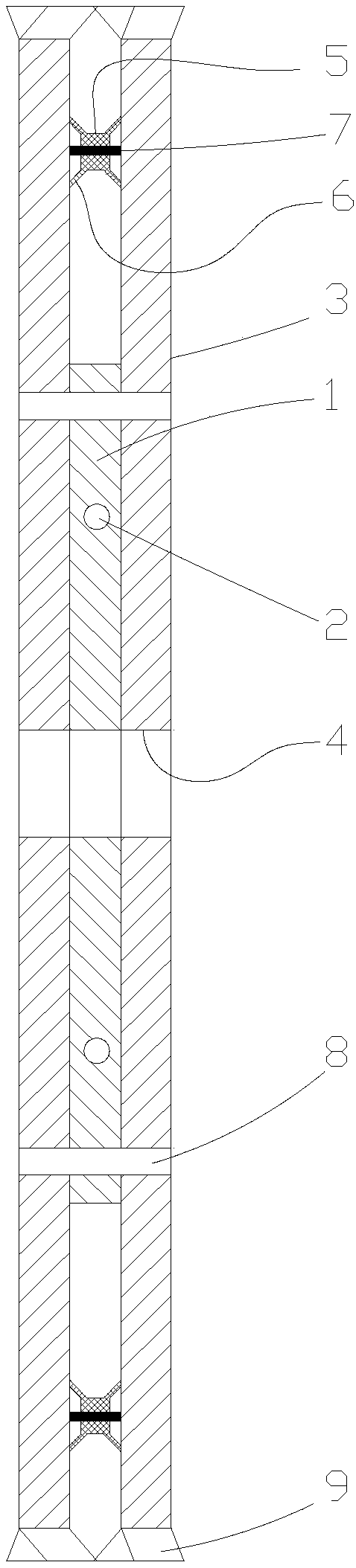

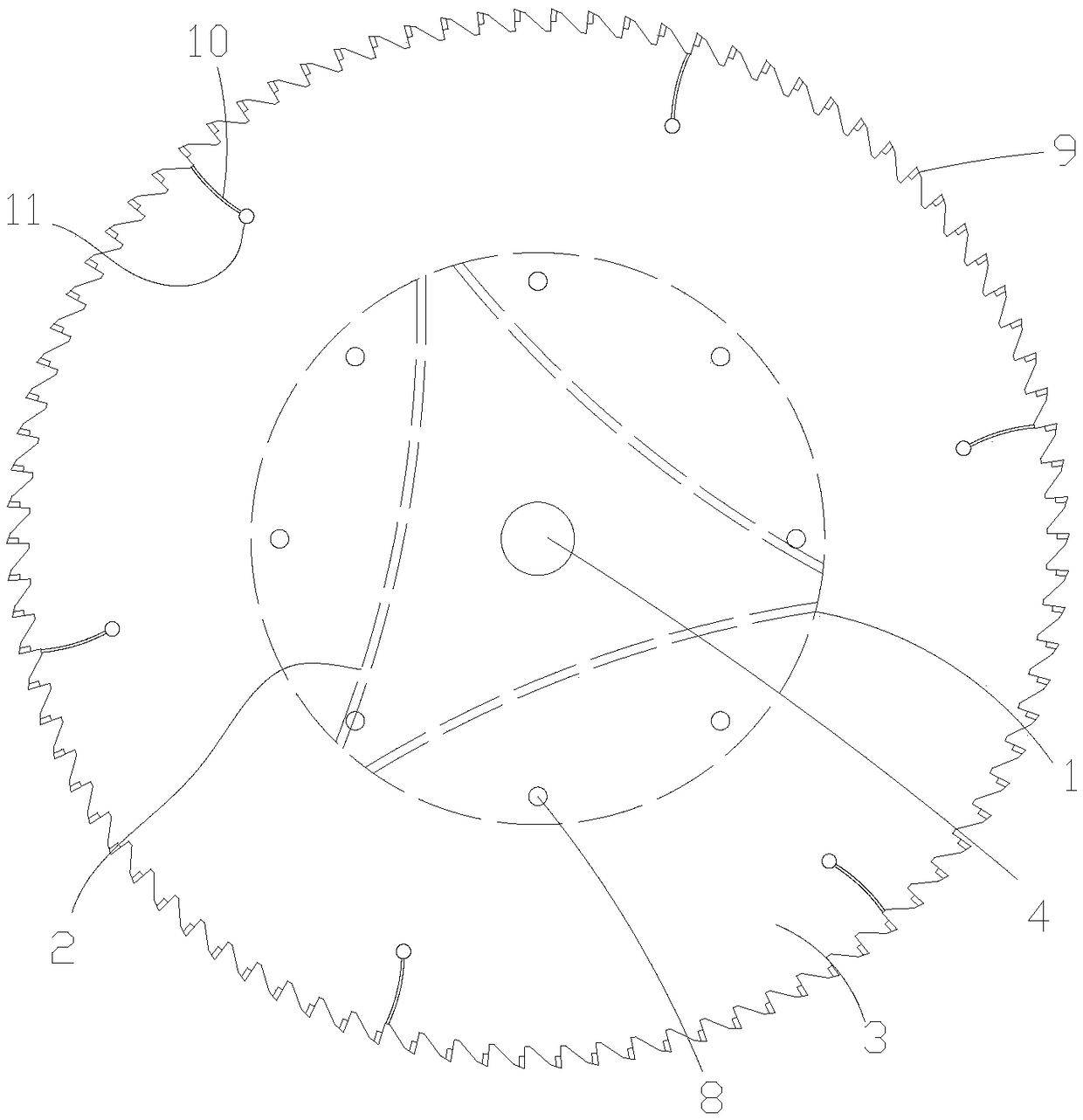

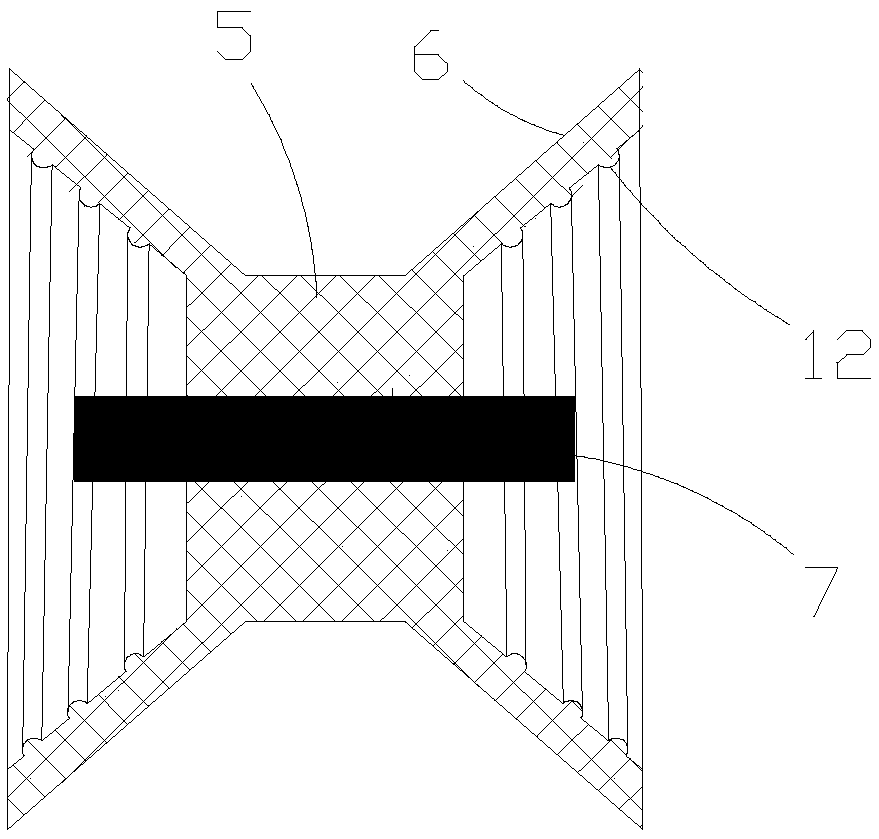

[0013] Example. Silent saw blades for wood cutting, such as figure 1 As shown, the copper core plate 1 is included, and the outer peripheral surface of the copper core plate 1 is provided with a plurality of air holes 2 whose axes are arc-shaped. Both sides of the copper core plate 1 are provided with a cutting disc 3, and the cutting disc 3 is provided with Through the fixing hole 4 of the copper core disk 1, the outer edge of the cutting disk 3 extends outward beyond the outer edge of the copper core disk 1, and a plurality of rubber columns 5 surrounding the copper core disk 1 are arranged between the two cutting disks 3, Both ends of the rubber column 5 are provided with trumpet-shaped elastic body 6, and the rubber column 6 is provided with a screw 7, and the two ends of the screw 7 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com