Steel slag multi-stage treatment method

A treatment method and steel slag technology, applied in grain treatment, chemical instruments and methods, solid separation, etc., can solve the problems of comprehensive utilization of steel slag that have not yet been realized, and achieve the effect of improving the value of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

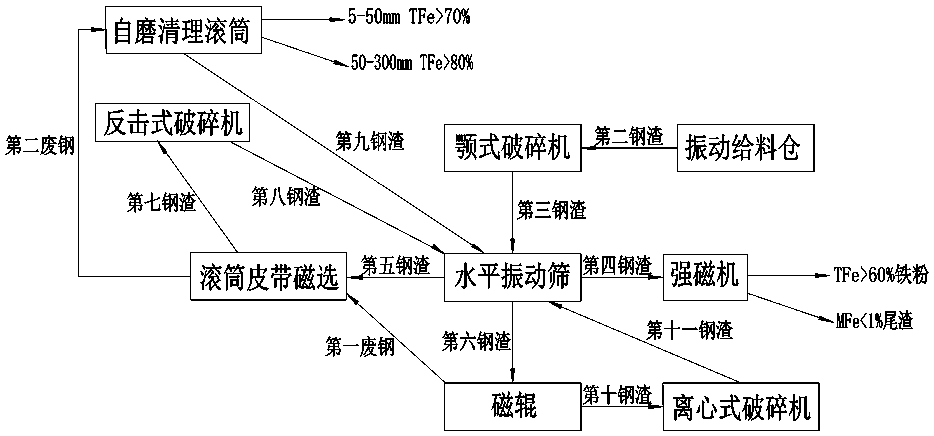

[0034] The flow process of the steel slag multistage treatment method of the present embodiment is as follows figure 1 , including the following steps:

[0035] (1) The hot and stuffy steel slag is discharged, loaded into the contractor's dump truck, transported to the steel slag factory material shed for transfer, and enters the vibrating feeding bin through the feeding platform.

[0036] (2) Vibrating feeding into the hopper, the diameter range of the feeding is 0-800mm; the steel slag raw material transfer station with a diameter of more than 800mm has a separate environmental protection dust removal pretreatment area, which is cut to less than 300mm by oxygen and then processed online.

[0037] (3) Steel slag is divided into >300mm and 0~300mm two types by pre-selection drum screen. After sorting those larger than 300mm, part of them will be returned to the cutting area for cutting.

[0038] (4) The 0-300mm steel slag is directly sent to the jaw crusher, and after crushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com