Furnace flue heat exhaust gas drying closed pulverizing coal-fired boiler unit with exhaust water recovery

A coal-fired boiler, dry and closed technology, applied in the fields of pulverization, coal combustion, flue gas water recovery, and boiler air supply, can solve the problems of low thermal efficiency of lignite boilers, high heat loss of boiler exhaust, and difficulties in stable combustion of boilers, etc. problems, to achieve the effect of improving implementability, improving combustion stability, and economical and effective recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

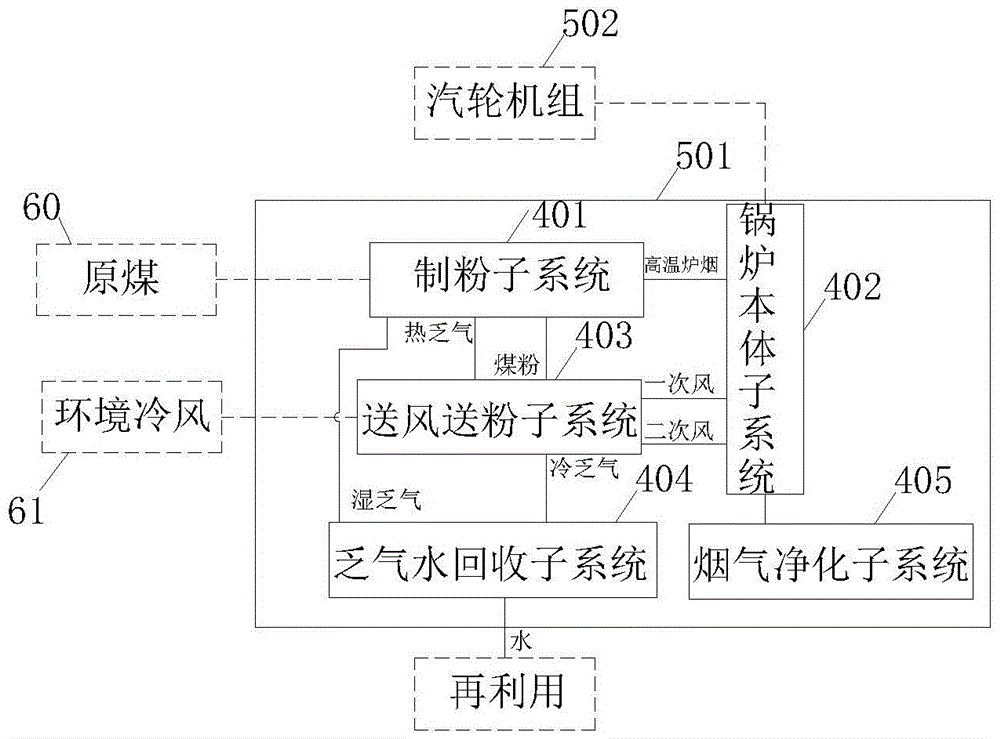

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiment 1 is combined with the accompanying drawings to describe the furnace flue heat exhaust gas drying closed-type pulverized coal-fired boiler with exhaust water recovery of the present invention. The unit elaborates in detail.

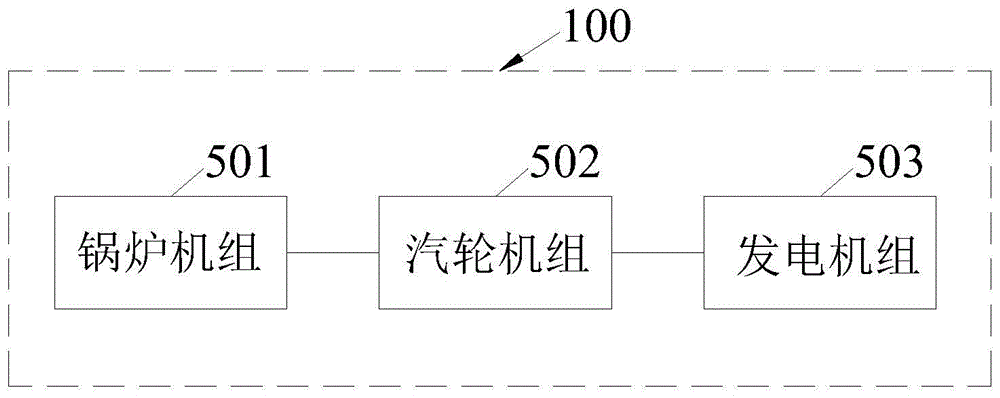

[0026] figure 1 It is a structural block diagram of the power generation system in the embodiment of the present invention.

[0027] Such as figure 1 As shown, the power generation system 100 includes: a closed-type pulverized coal-fired boiler unit 501 with exhaust gas and water recovery, a steam turbine unit 502 and a generator unit 503 .

[0028] The heat generated by the combustion of raw coal in the closed-type pulverizing coal-fired boiler unit 501 with exhaust gas and water recovery heats the water, and the water is heated to form high-temperature and high-pressure steam that enters the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com