A kind of industrial waste gas treatment method

A treatment method and technology for industrial waste gas, applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve problems such as easy drop of microorganisms, single biofilm structure, displacement, etc., to increase space utilization and realize Effects of updated use and various functional structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0037] Such as Figure 1-Figure 8 Shown, a kind of industrial waste gas treatment method described in the present invention, this method comprises the following steps:

[0038] S1: Spray water to remove dust from the waste gas generated during production;

[0039] S2: cooling the gas after dedusting;

[0040] S3: Perform initial desulfurization treatment on the cooled gas;

[0041] S4: Pass the gas after initial desulfurization into the biofilter for final filtration;

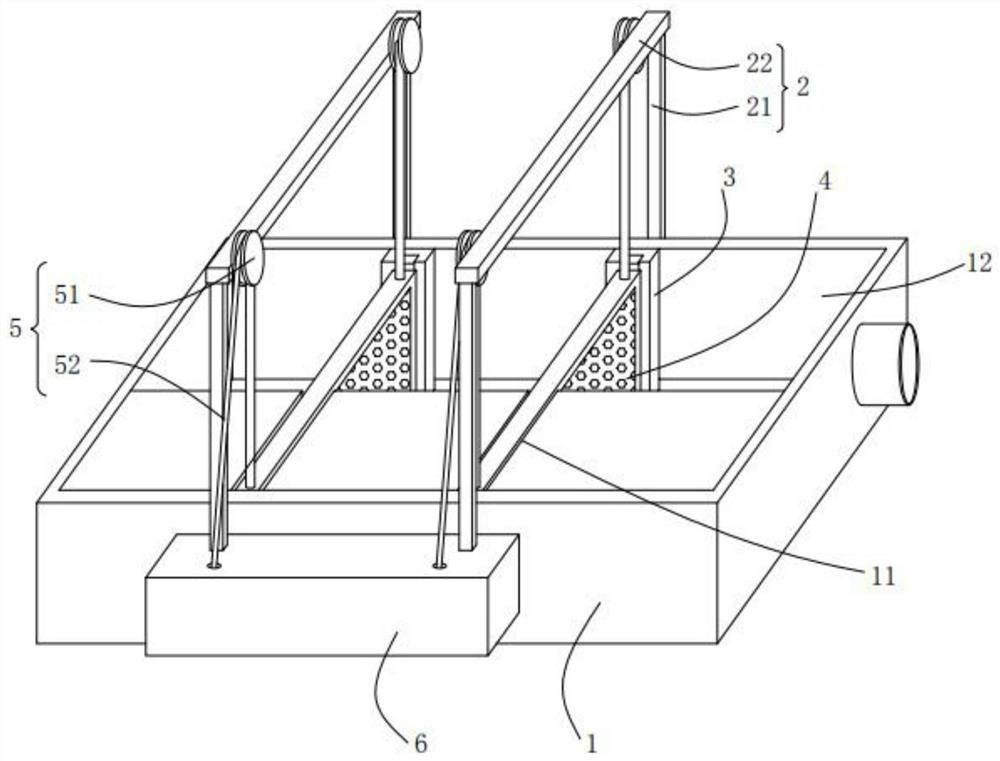

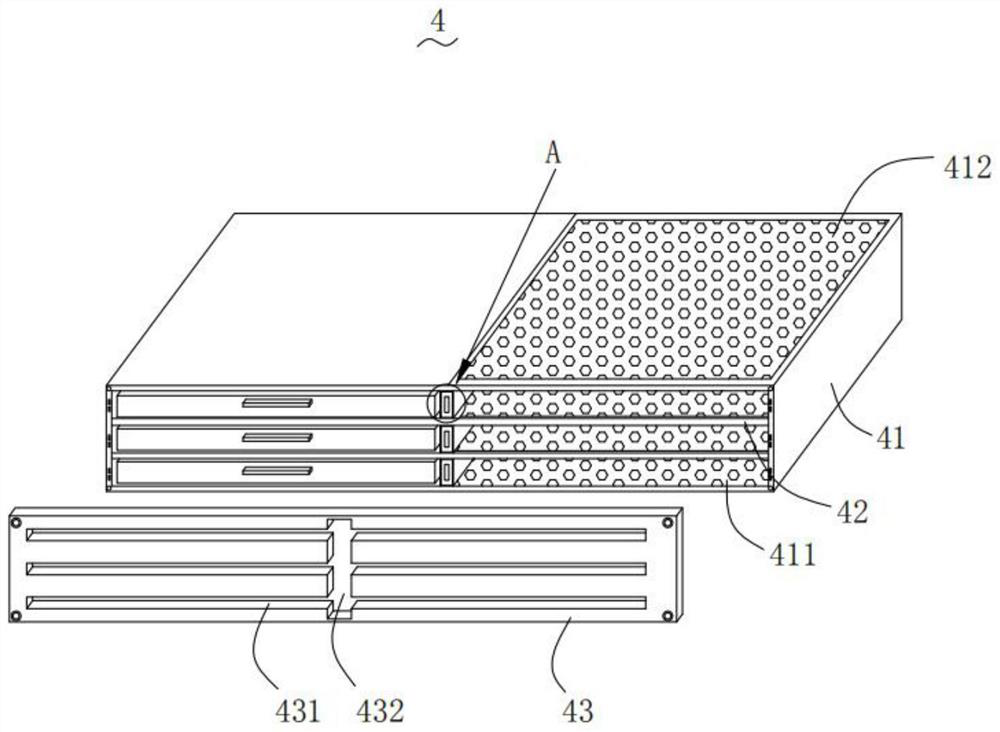

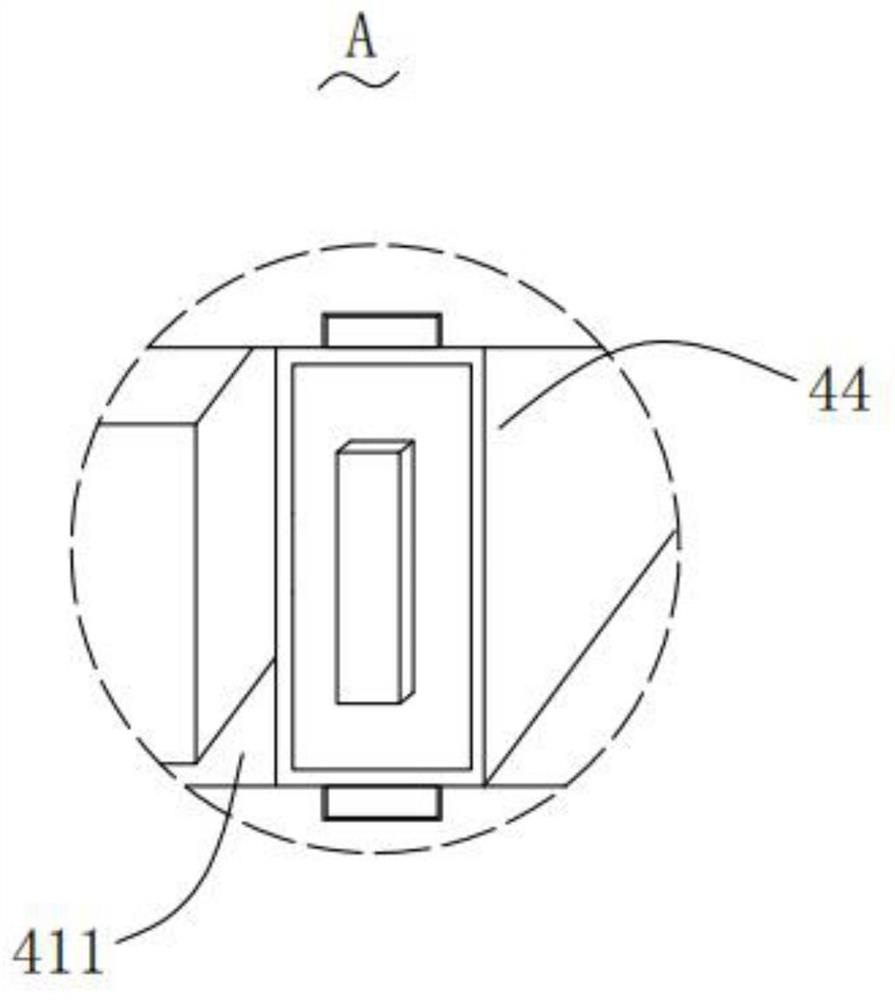

[0042] The biofilter used in this method includes a base 1, a support mechanism 2, a sliding seat 3, a storage mechanism 4, a lifting mechanism 5, a biofilm mechanism 7 and a locking mechanism 8; the inner wall of the base 1 is provided with the sliding seat 3. The sliding seat 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com