Rotating shaft torque measurement method and system based on wireless technology

A technology of torque measurement and wireless technology, applied in the field of torque measurement of rotating shafts, can solve the problems of reduced safety and reliability, difficult wiring of power supply systems, system interference, etc., and achieves lightweight structure, low power consumption, and good anti-interference ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

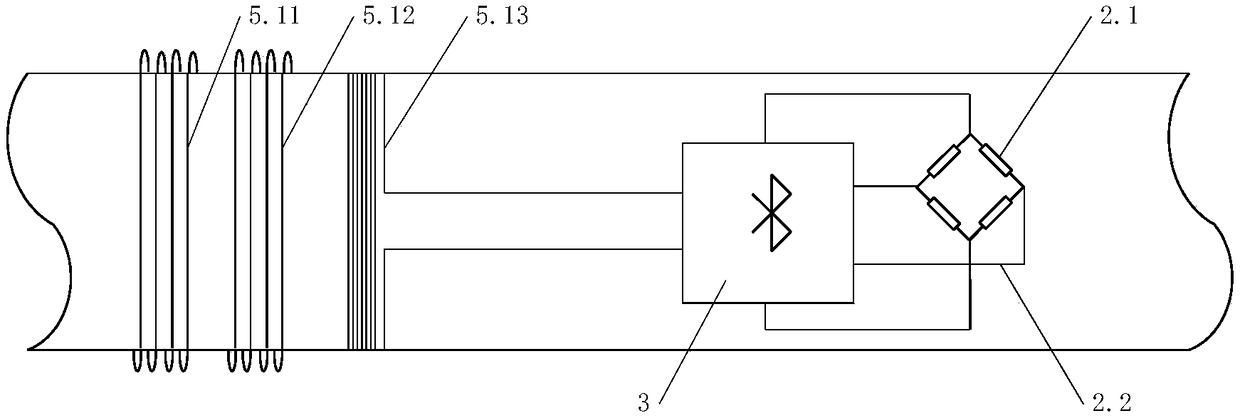

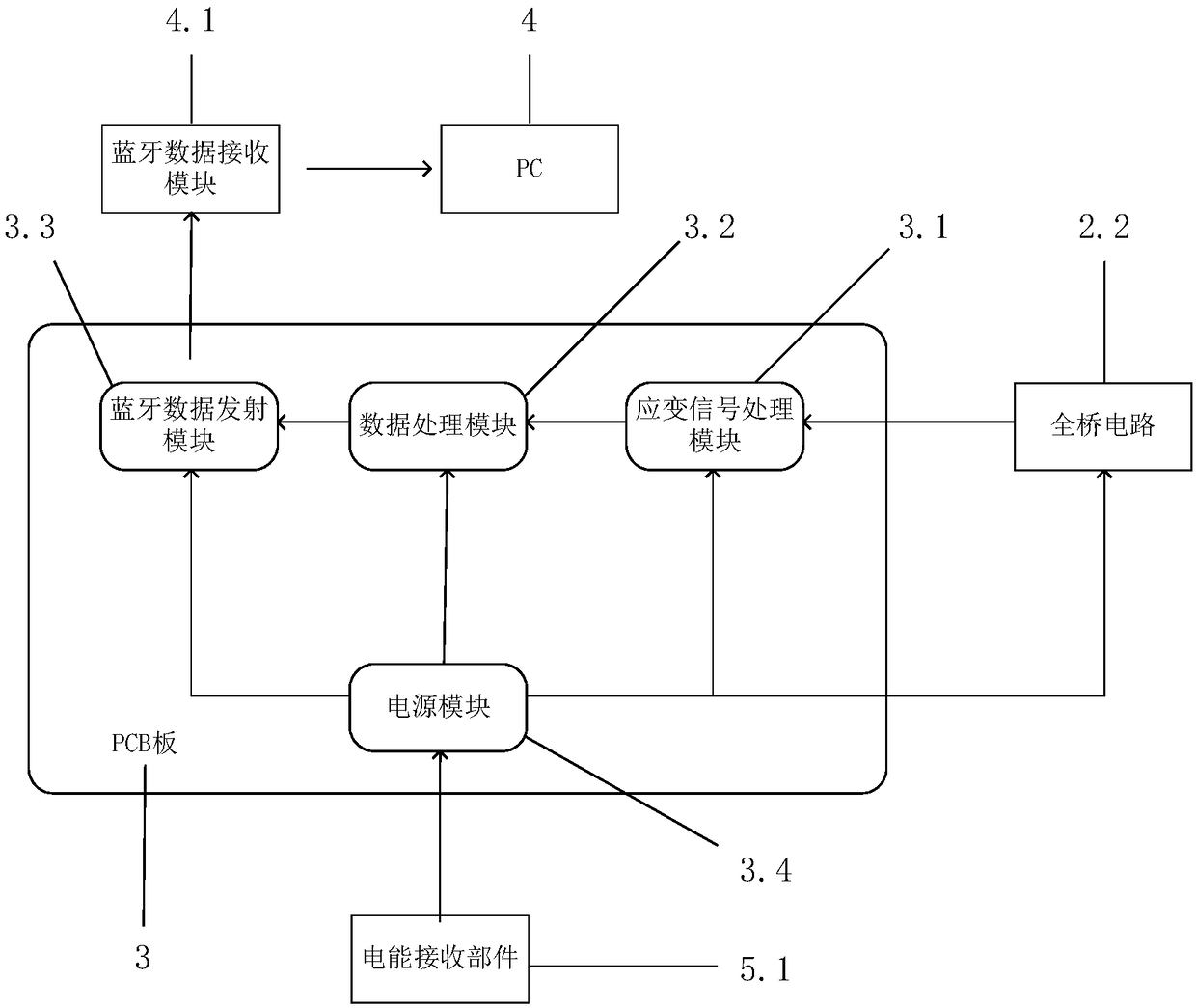

[0031] Such as Figure 1~6 As shown, the rotating shaft torque measurement system based on wireless technology designed in this embodiment includes a strain gauge type torque sensor 2 , an integrated circuit board 3 , a host computer 4 and a wireless power supply device 5 . in:

[0032] The strain gauge type torque sensor 2 includes four strain gauges 2.1 arranged along the axial direction of the rotating shaft 1 at ±45°, and the four strain gauges 2.1 form a full bridge circuit 2.2, which can output a voltage signal proportional to the torque M, That is, the voltage analog signal.

[0033] The wireless power supply device 5 includes a power receiving component 5.1 and a power transmitting component 5.2. The power transmitting part 5.2 includes a high-frequency signal generator 5.21, a power amplifier circuit 5.22 and an exciting coil 5.23 connected in sequence, and the exciting coil 5.23 is set within the wireless power receiving range of the power receiving part 5.1. The ...

Embodiment 2

[0043] Based on the rotating shaft torque measurement system provided in Embodiment 1, this embodiment provides a method for measuring rotating shaft torque based on wireless technology. The method comprises the steps of:

[0044] 1) When the rotating shaft 1 rotates, the strain gage torque sensor 2 collects a voltage analog signal and transmits it to the strain signal processing module 3.1.

[0045] 2) The strain signal processing module 3.1 performs amplification, filtering and analog-to-digital conversion on the voltage analog signal to obtain a voltage digital signal.

[0046] 3) The data processing module 3.2 receives the voltage digital signal from the strain signal processing module 3.1, and transmits it to the upper computer 4 equipped with the Bluetooth data receiving module 4.1 through the Bluetooth data transmitting module 3.3, and obtains the rotation axis through the processing of the upper computer 4 1 torque value. In this torque system, the torque of the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com