Combined unclogging method for coiled tubes of horizontal well

A technology for horizontal wells and tubing, which is applied in the field of composite plugging removal of coiled tubing in horizontal wells. It can solve the problems of long construction period of tubing drilling, grinding and descaling, long acidizing construction time, composite blockage of horizontal wells, etc., and achieves increased wellbore treatment effect, Improve the effect of plugging removal and the effect of a wide range of plugging removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained below in conjunction with the drawings.

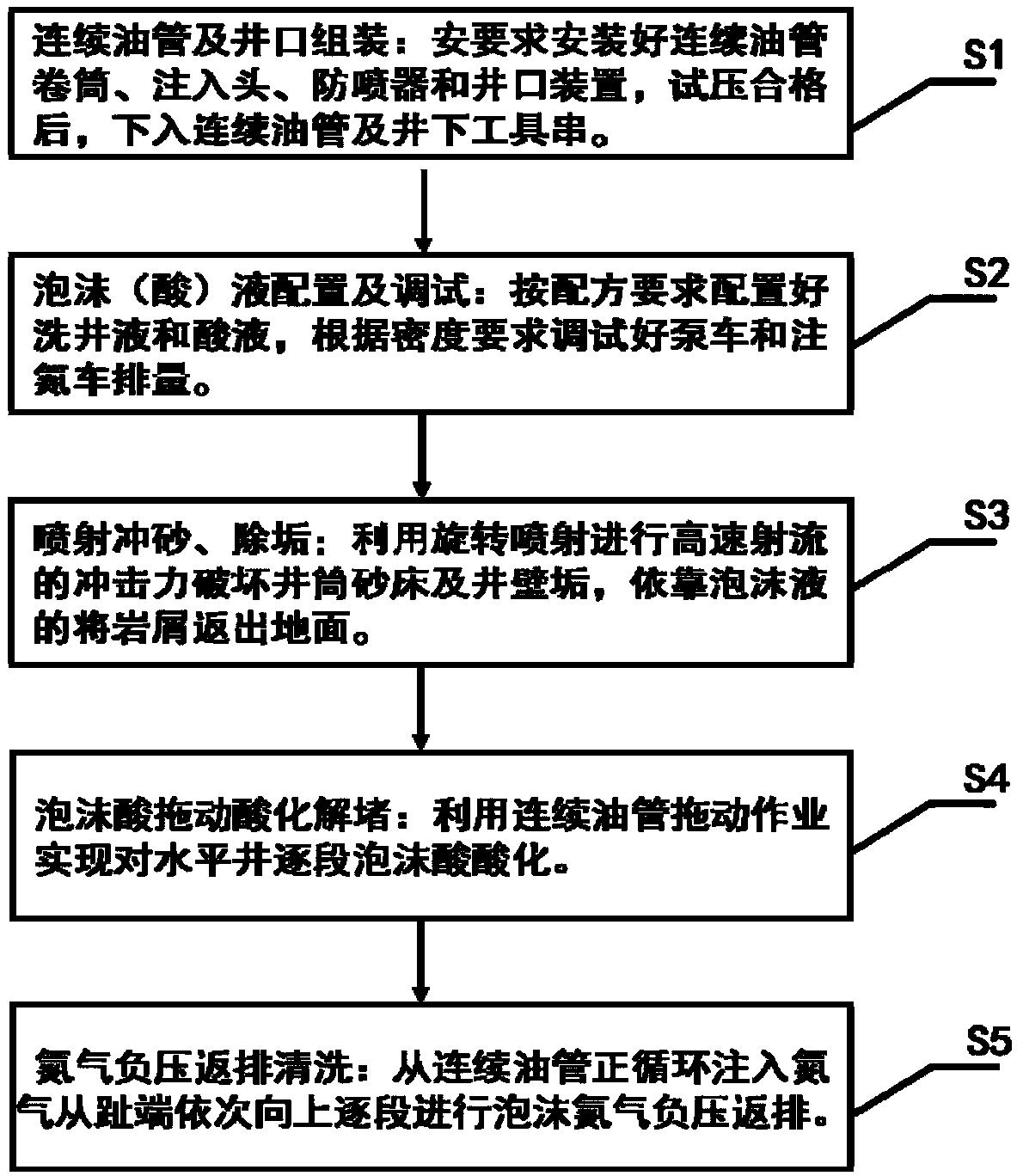

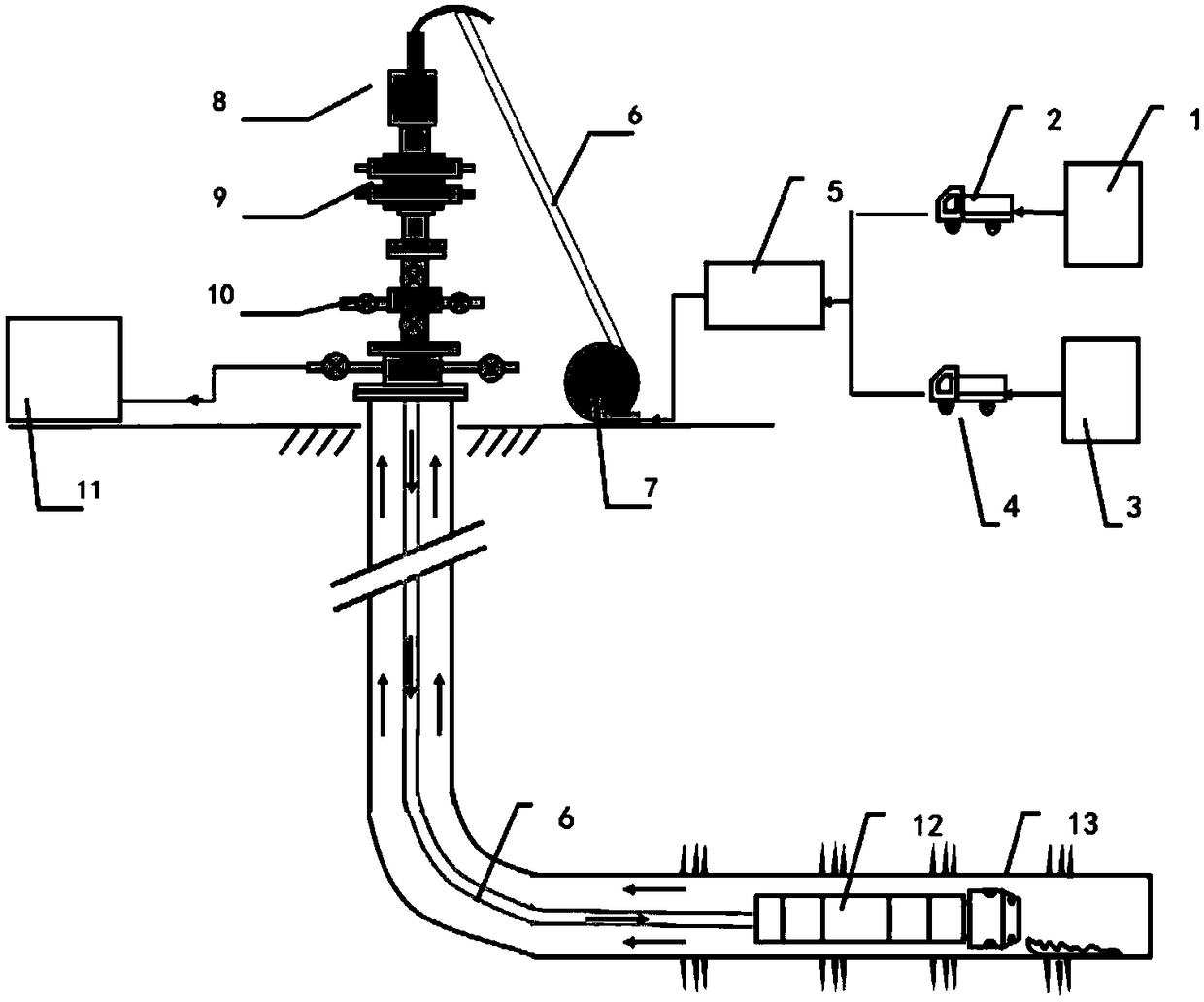

[0032] Such as Figure 1 to Figure 4 Shown. The present invention provides a horizontal well coiled tubing composite deblocking method. The method adopts coiled tubing 6 and uses the impact force of a rotary jet tool to break the wellbore sand bed and well wall scale, and nitrogen foam acid dissolves blockages and foam near the well. Methods such as negative pressure flowback to dredge the oil flow channel for compound deblocking include the following process steps:

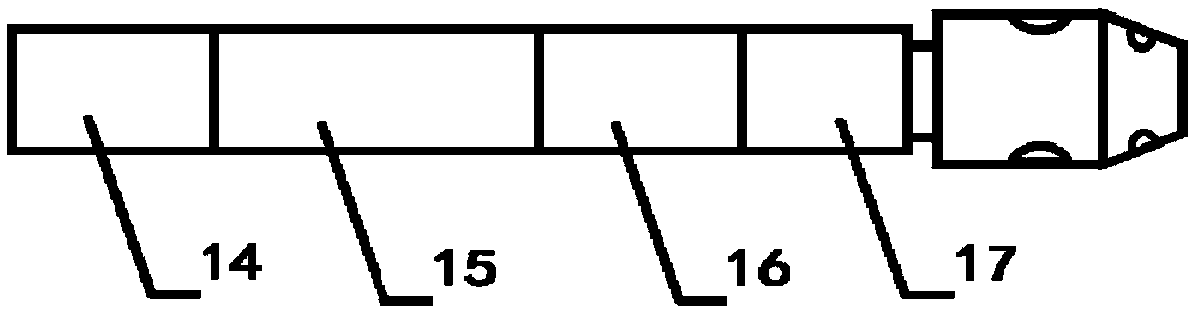

[0033] 1) Coiled tubing installation: install the coiled tubing reel 7, the coiled tubing injection head 8, the coiled tubing blowout preventer 9, and the wellhead device 10, and perform the coiled tubing blowout preventer system and wellhead pressure test as required, and install the downhole casing 13 The coiled tubing 6 and the downhole rotary jet tool string 12 in the inside are near the deflection point. The rotary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com