Novel road crash barrier

An anti-collision guardrail and guardrail technology, which is applied to roads, roads, road safety devices, etc., can solve the problems of buffer effect and protection degree limitation, vehicle paint surface wear, etc., to improve service life, improve strength, and reduce interface holes. and defect effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

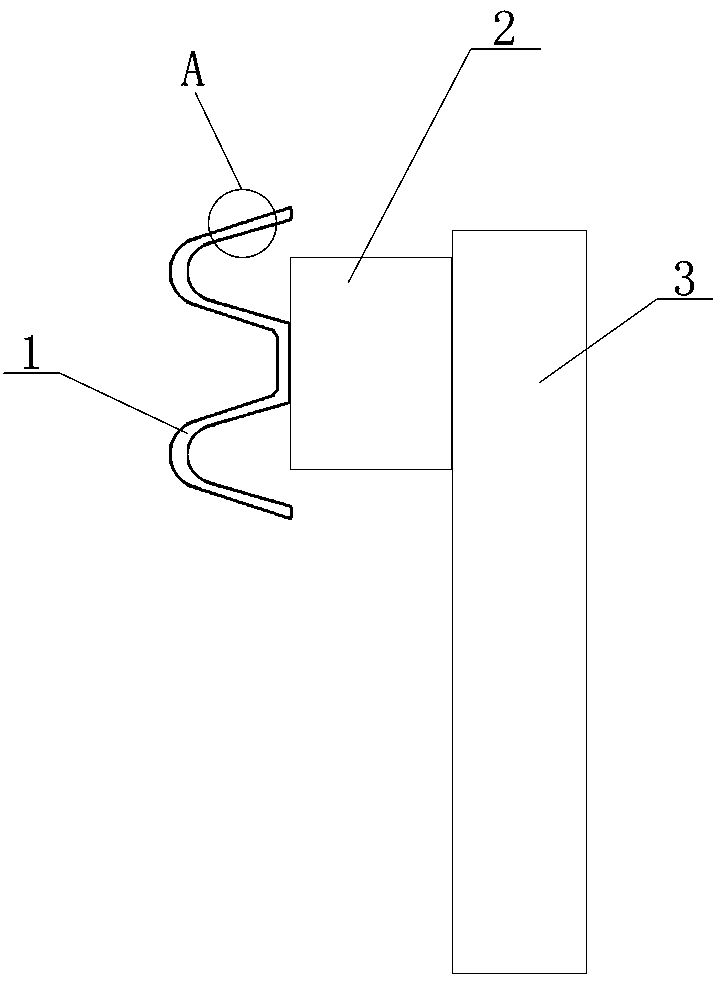

[0029] refer to Figure 1 to Figure 2 , the present invention includes a wavy guardrail 1;

[0030] The guardrails 1 are connected horizontally head-to-tail, and the head-to-tail connections are fastened to one side of the buffer ring 2 through fastening bolts; the other side of the buffer ring 2 is fastened to the support column 3;

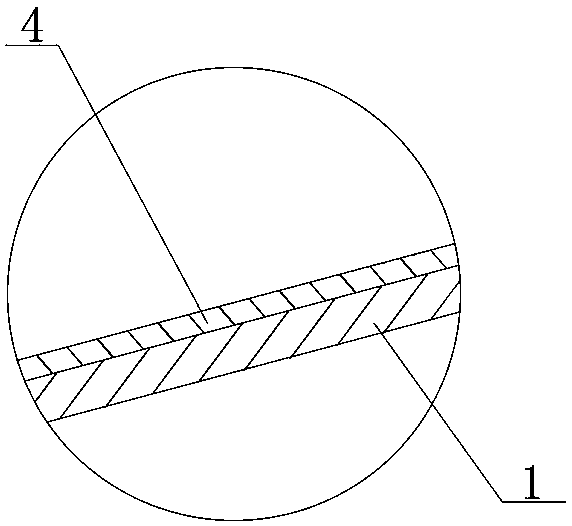

[0031] A buffer layer 4 is provided on the outside of the guardrail.

Embodiment 2

[0033] In order to improve the elasticity, strength and aging resistance of the buffer layer, the present invention improves the material of the buffer layer. Specifically, the buffer layer is prepared according to the following steps:

[0034] Step 1) Weigh raw materials: 100 parts of butadiene rubber, 30 parts of polypropylene resin, 10 parts of phenolic resin, 8 parts of urea-formaldehyde resin, 5 parts of vulcanizing agent sulfur, 3 parts of dioctyl phthalate, 3 parts of diatomaceous earth , 2 parts of hexamethylcyclotrisiloxane, 2 parts of glass fiber, 1 part of stearic acid, 1 part of talcum powder;

[0035] Step 2) Diatomite modification: Put the diatomite into a heating furnace for high-temperature calcination. The temperature in the heating furnace is 750°C, and the calcination time is 30 minutes. Take it out, cool it to room temperature, and then add hexamethylcyclotrisil Oxygen, heated to 80°C, ultrasonic dispersion treatment for 5 minutes under heat preservation co...

Embodiment 3

[0040] In order to improve the elasticity, strength and aging resistance of the buffer layer, the present invention improves the material of the buffer layer. Specifically, the buffer layer is prepared according to the following steps:

[0041] Step 1) Weigh raw materials: 150 parts of butadiene rubber, 50 parts of polypropylene resin, 15 parts of phenolic resin, 12 parts of urea-formaldehyde resin, 7 parts of vulcanizing agent sulfur, 5 parts of dioctyl phthalate, 5 parts of diatomaceous earth , 3 parts of hexamethylcyclotrisiloxane, 3 parts of glass fiber, 2 parts of stearic acid, 1 part of talcum powder;

[0042] Step 2) Diatomite modification: Put the diatomite into a heating furnace for high-temperature calcination. The temperature in the heating furnace is 750°C, and the calcination time is 30 minutes. Take it out, cool it to room temperature, and then add hexamethylcyclotrisiloxane Alkanes, heated to 80 ° C, under the condition of heat preservation, ultrasonic dispersio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com