combing machine

A combing machine and combing technology, applied in the direction of combing machine, textile and paper making, fiber processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

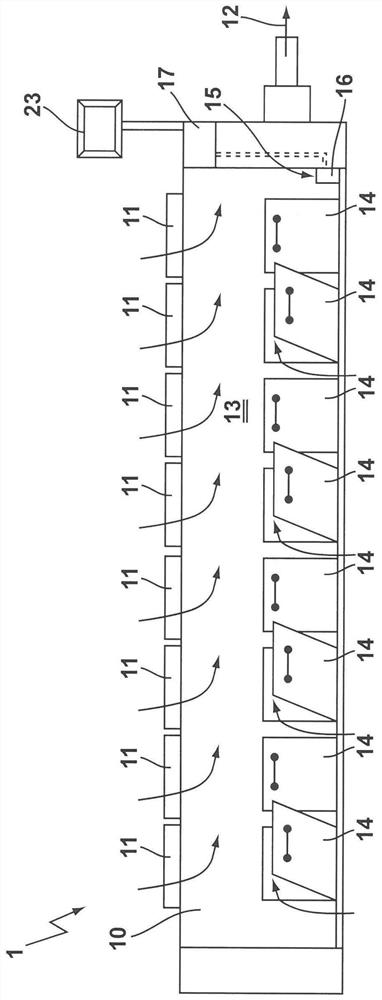

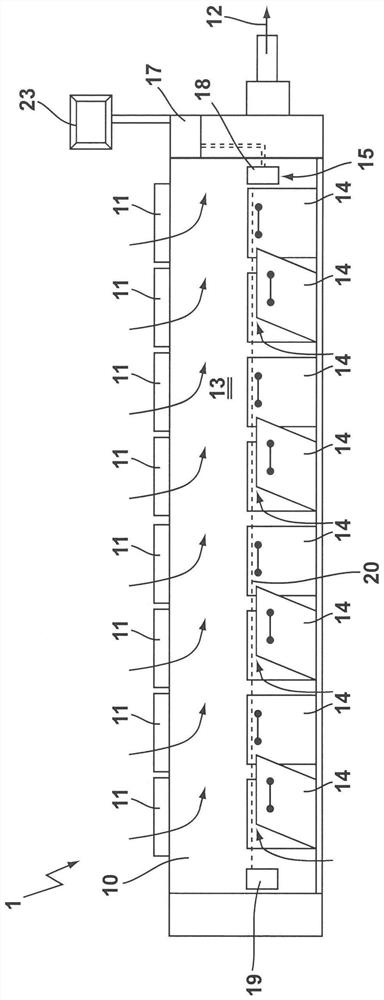

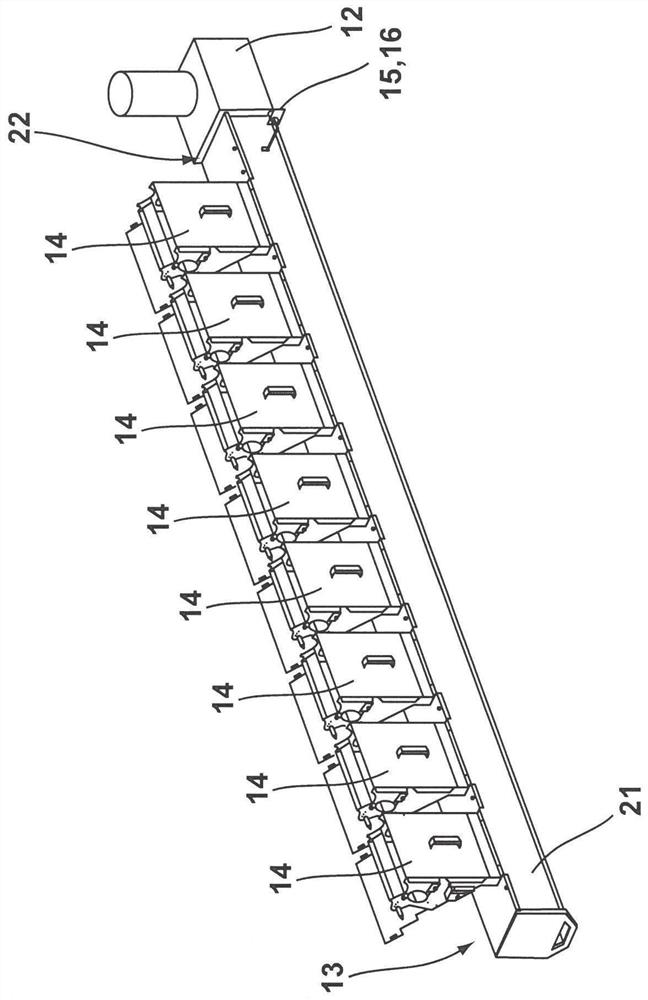

[0020] figure 1 with figure 2 A combing machine 1 with a housing 10 is shown schematically in each case. A plurality of combing units 11 are accommodated in the housing 10 , which are designed to process the laps, not shown in detail, which are fed to the combing units 11 . For example, eight maintenance flaps 14 are arranged on the front side of the housing 10 , wherein the closed state of the maintenance flap and the open state of the maintenance flap are respectively shown.

[0021] The combing machine also has a controller 17 which is connected to the combing unit 11 and controls the combing unit 11 via the controller. The suction mechanism 12 is shown schematically and the components carded from the lap are sucked by the air flow. Simplified here, the suction mechanism 12 is only connected to the housing 10, wherein a collection chamber 13 is formed in the interior of the housing 10 in a manner not shown in detail, in which the combed components from the combing unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com