Preparation method of columnar copper granular film

A copper particle, columnar technology, applied in the field of electrochemistry, can solve the problems of poor structure uniformity, complex process, single product form, etc., and achieve the effects of low cost, simple preparation process and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 0.6g acetic acid to 100g water, stir to dissolve, use it as electrolyte, copper sheet as anode, platinum sheet as cathode, the distance between anode and cathode is 2.0cm, anodic oxidation is carried out at 40°C and 40V DC, the reaction time for 20min. After the anodizing experiment, the copper sheet was removed and cleaned with deionized water.

[0024] Add 3.2g of copper sulfate and 0.06g of sodium 2-cyclohexylaminoethanesulfonate into 100g of water, stir and dissolve, use this solution as the electrodeposition solution, use the copper sheet that has been anodized before as the cathode, the platinum sheet as the anode, and the cathode The distance from the anode is 2.0cm, at room temperature, the current density is 85mA / cm 2 DC electrodeposition under the condition of 2min. After the experiment, the sample sheet was removed, washed with deionized water, and dried with warm air to obtain a columnar copper particle film.

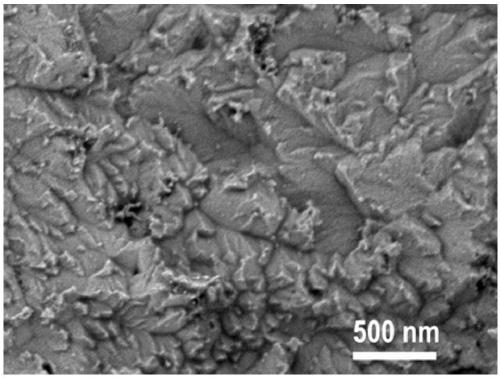

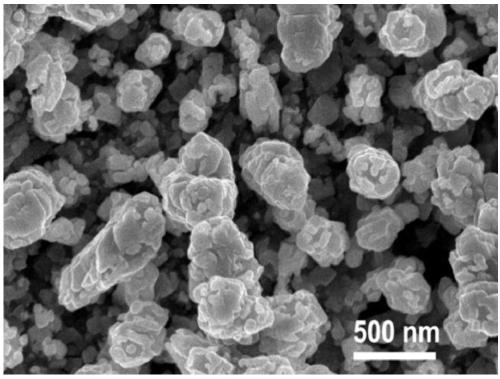

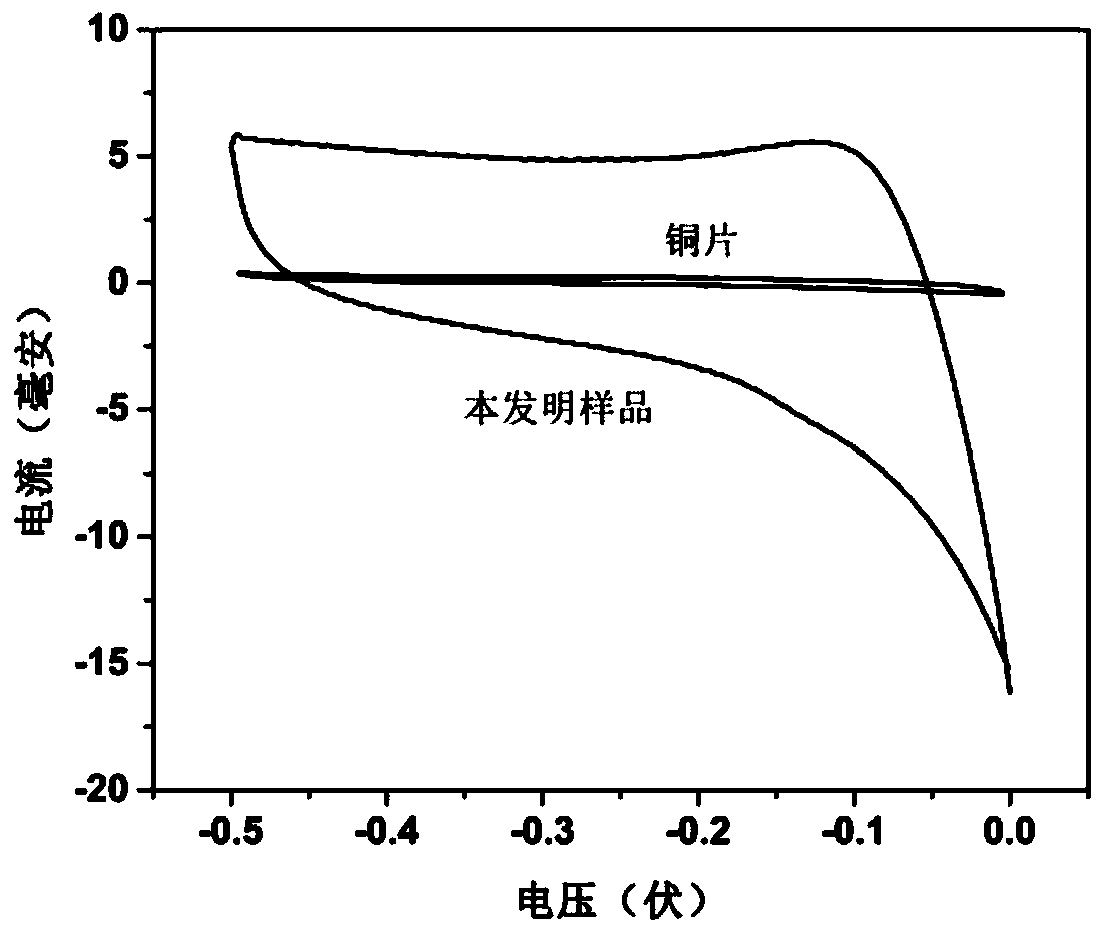

[0025] figure 1 It is the surface morph...

Embodiment 2

[0029] Add 1.0g acetic acid to 100g water, stir to dissolve, use it as electrolyte, copper sheet as anode, platinum sheet as cathode, the distance between anode and cathode is 2.0cm, anodic oxidation is carried out at 40°C and 10V DC, the reaction time for 30min. After the anodizing experiment, the copper sheet was removed and cleaned with deionized water.

[0030] Add 6.5g of copper sulfate and 0.1g of sodium 2-cyclohexylaminoethanesulfonate to 100g of water, stir and dissolve, use this solution as the electrodeposition solution, use the copper sheet that has been anodized before as the cathode, the platinum sheet as the anode, and the cathode The distance from the anode is 2.0cm, at room temperature, the current density is 150mA / cm 2 DC electrodeposition under the condition of 1min. After the experiment, the sample sheet was removed, washed with deionized water, and dried with warm air to obtain a columnar copper particle film, the performance of which was similar to that ...

Embodiment 3

[0032] Add 0.1g acetic acid to 100g water, stir to dissolve, use it as electrolyte, copper sheet as anode, platinum sheet as cathode, the distance between anode and cathode is 2.0cm, anodic oxidation is carried out at 40°C and 50V DC, the reaction time for 5min. After the anodizing experiment, the copper sheet was removed and cleaned with deionized water.

[0033] Add 0.5g of copper sulfate and 0.01g of sodium 2-cyclohexylaminoethanesulfonate into 100g of water, stir and dissolve, use this solution as the electrodeposition solution, use the copper sheet that has been anodized before as the cathode, the platinum sheet as the anode, and the cathode The distance from the anode is 2.0cm, at room temperature, the current density is 25mA / cm 2 DC electrodeposition under the condition of 5min. After the experiment, the sample sheet was removed, washed with deionized water, and dried with warm air to obtain a columnar copper particle film, the performance of which was similar to that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com