Laser derusting system of sheet metal

A metal plate, laser derusting technology, applied in the direction of laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of complicated sewage process, damage to the plate area, and large consumption of chemical reagents, etc., to achieve a wide laser radiation area and high efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with specific embodiments.

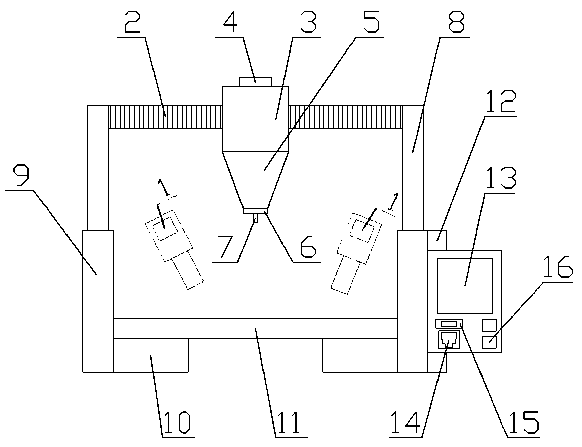

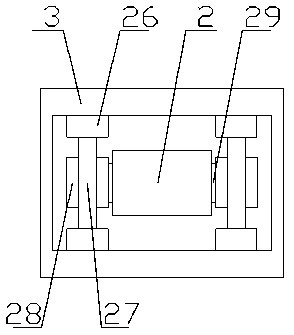

[0059] refer to Figure 1-3 , a metal plate laser rust removal system, including a hyperspectral image acquisition device 1, a support plate 11 for carrying a metal plate, and also includes a lateral movement mechanism, a longitudinal movement mechanism, a vertical movement device, a laser output system, a monitoring system, and a gas injection system , collection system and control terminal; the laser output system and support plate 11 are arranged on the upper side of the longitudinal movement mechanism, the laser output system and the lateral movement mechanism are all arranged on the top of the support plate 11, the control terminal is arranged on one side of the longitudinal movement mechanism, and the vertical movement device Set on both sides of the support plate 11 and fixedly connected with the lateral movement mechanism; the cleaning system realizes the three-dime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com